Tig Welding Carbon Steel parts using pulse and without pulse

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

Tig welding carbon steel motorcycle oil filter canisters today at Roy Crumine's shop.

These are fairly simple parts but there is one requirement for zero melt thru that requires some attention.

There is a washer on one end of the part that is only .038” thick.

who knows why? but that is less than 1mm thick and it is welded to a much thicker fitting.

So

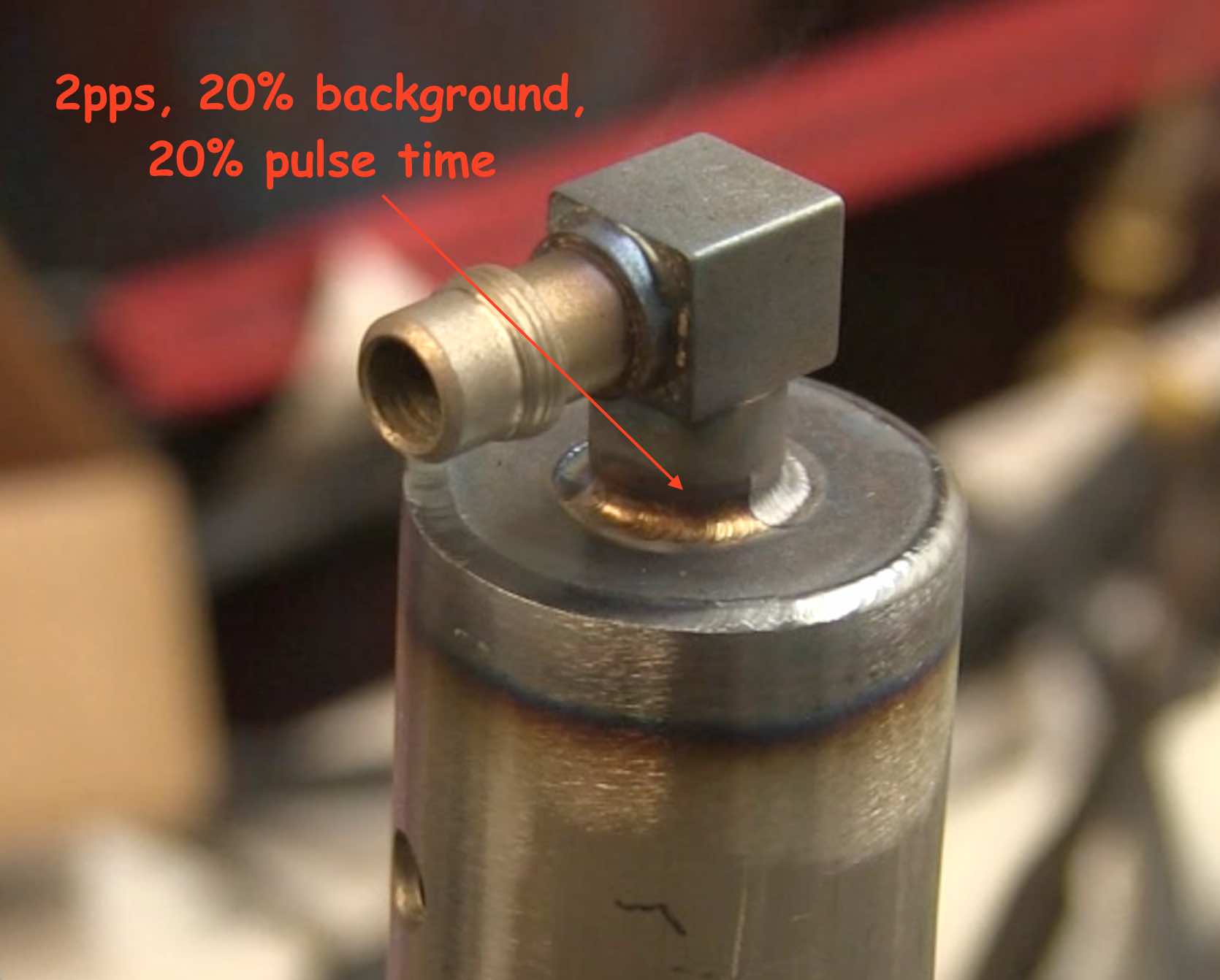

the solution was to not use filler metal and to use pulse settings of

around 2pps, 20% pulse time, and 20% background current.

Pulse settings with low background current and low pulse time are helpful when you are trying to limit heat input on.

The round welds are being done using a positioner and Roy has a MK Cobra turn on loan along with his Atlas positioner he got off Ebay.

Here is a tip for when you use a positioner…

And its based on manual welding speeds.

After watching lots of really good tig welders, I have noticed most of them add rod about once per second….

and they progress the torch about 1/8” (3.2mm) per second too.

If you think about it, thats a pretty simple formula.

1/8” per second is travel speed. or 60/8 per minute whick equals 7.5 inches per minute.

But all you need to do to get a good starting point is mark off a piece a tape in 1/8” increments.

then wrap the tape on the part you are about to weld and set the positioner to a speed where one of those marks passes a fixed point every second.

If you have a digital readout you can always translate the diameter of your round part into circumference using pi 3.14 …so a one inch part will be 3.14 of weld. so it would take 2 rpm to reach 7.28.

and 2 rpm is exactly the speed used on the once inch round weld in this video.

These parts are housings for a motorcycle oil filter and there is a seating surface underneath the first fitting you saw welded in the video.

that means no melt thru is allowed…

It would seem that going to a thicker washer would have been a easy fix on these parts but that was not an option for Roy…he had to use what the customer specified.

Aluminum backer bar helps prevent melt thru for tig welding carbon steel, or stainless steel

But because of the zero melt thru requirement, a piece of aluminum

backing was used and it actually worked very well ( along with pulse

settings of 2pps, 20% pulse time, and 20% background current.)

For the stationary welds, filler wire was used (.030” er70s2) and no puse current was needed.

Furick #12 pyrex cup for tig welding carbon steel, stainless, inconel, and even titanium

Read an old article about using large tig cups here

You dont always need great argon coverage and a long stickout....

but sometimes you do.

For tig welding 4130 chromoly, stainless, inconel, and titanium, this cup is a great choice.