Stainless Steel Welding Tips for TIG

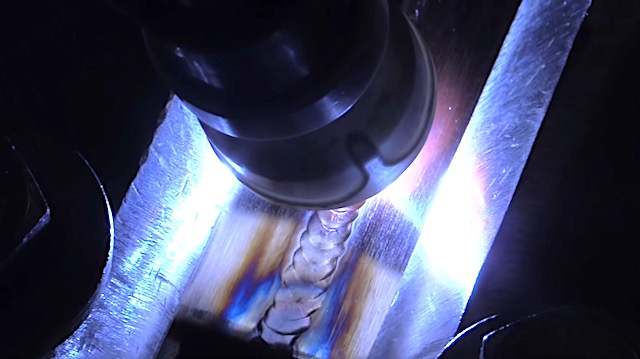

This video is about Stainless Steel Welding tips and I am welding a water manifold for a local factory.

Ideally, stainless square tubing would be used for the body but the stainless sheet was readily available in JD's shop so he decided to cut pieces on the plasma cam and use outside corner joints for the body of the manifold.

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

TIG Welding Stainless Steel pipe Root pass technique

This short video shows bridge tacks vs penetrated tacks, root pass technique and all settings used

Tips for stainless steel welding using Gas Tungsten Arc Welding (gtaw)

- Some welds require a high purity argon purge. an example of this is sanitary tubing for food service applications...But some stainless welds can be adequately protected on the back side using aluminum or copper backing.

- Use a dedicated Stainless steel wire brush...one that has strictly been used on stainless only...and make sure its clean.

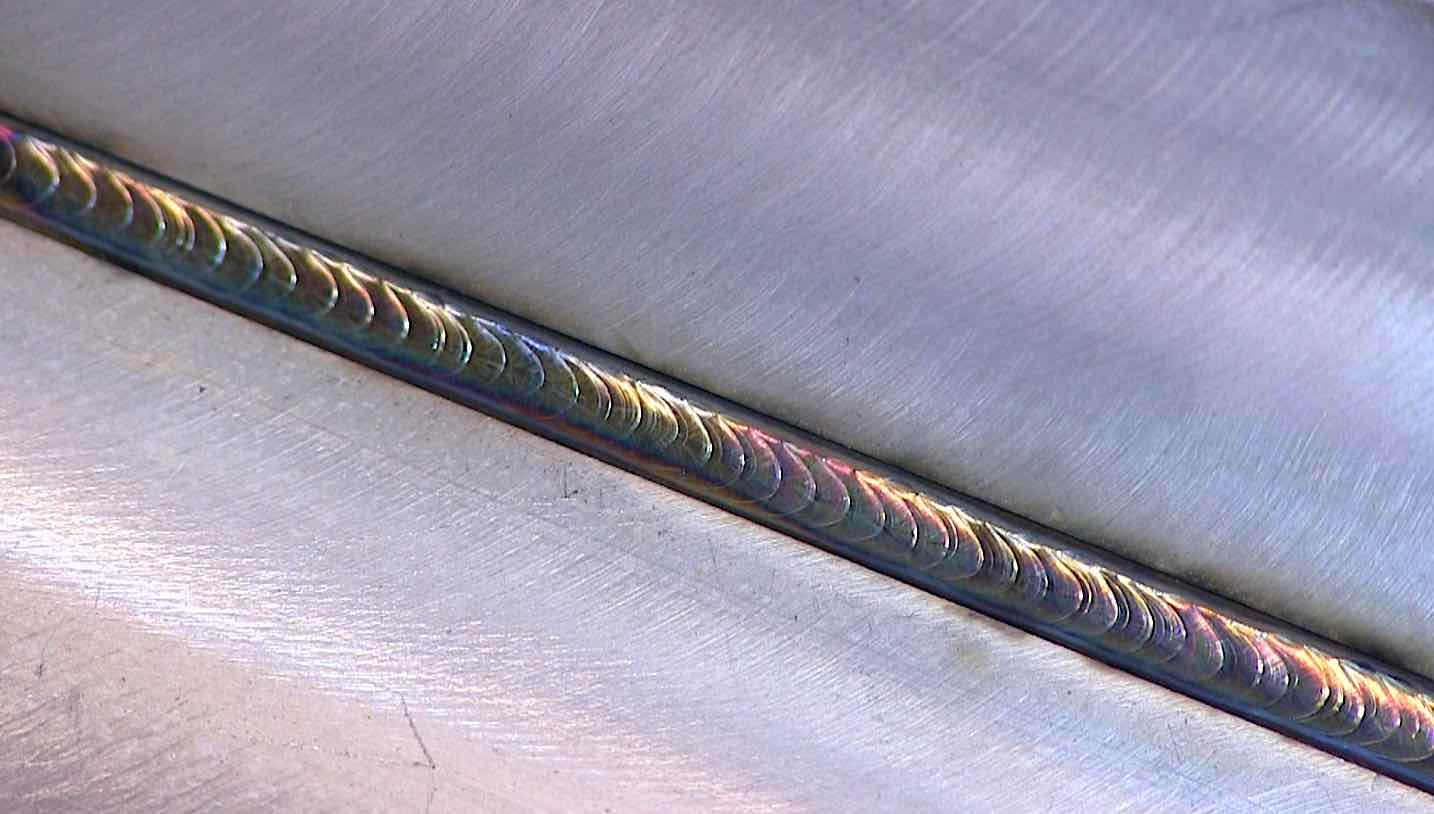

- Discoloration is basically oxidation. Grey and black indicates sever oxidation and straw thru blue and purple indicate slight oxidation. its best to limit discoloration my using a gas lens cup along with chill bars if possible.

- Stainless Steel is less thermally conductive than carbon steel and requires about 2/3 the amperage in some cases. For the outside corner welds in this video, I used 100 amps for .125" thick 304 stainless steel whereas I probably would have used 125 amps if the part were carbon steel.

- Using one size smaller filler wire can be helpful for stainless steel welding because too large a filler requires more amperage to flow smoothly.

- Clean the part before welding. Sometimes an acetone wipe is enough but the metal needs to be free from tape residue, shop dust, or any other coatings before welding.

Why use Chill Blocks?

300 series stainless steels are susceptible to a phenomenon known as carbide precipitation as a result of carbon combining with chromium to for create chromium depleted areas.

this condition can cause stress corrosion cracking.

That is why any stainless steel welding procedure should be written to limit the time the metal stays at elevated temperature.

Chill blocks are very effective in increasing the cooling rate and limiting the time at high temperature.

Another benefit is that chill blocks greatly help with discoloration.

Using a combination of a large size gas lens along with chill blocks limits distortion, limits discoloration, and limits the time at high temperature.

Filler metal

There are many different types of stainless steel but the most common is 300 series.

And the most common 300 series is 304

er308L filler is used to weld 304 stainless steel and for this video, I used 1/16" (1.6mm) er308L filler metal

What is electro polishing and How can it help maintain Stainless properties?

During the welding process, heavy oxides can form and that oxide layer is not as corrosion resistant as it should be.

Electropolishing removes a layer of metal and exposes fresh stainless for the highest corrosion resistance.