Welding Stainless Steel

"stainless steel takes about 1/3 less amperage than carbon steel !"

- HOME

- TIG WELDING

- Welding Stainless Steel

I have created a No BS TIG workbook for you to help you learn to TIG weld...and its free

Download your Free TIG workbook here

Download your Free TIG workbook here

Tig Welding Stainless walking the cup vs free hand multi pass

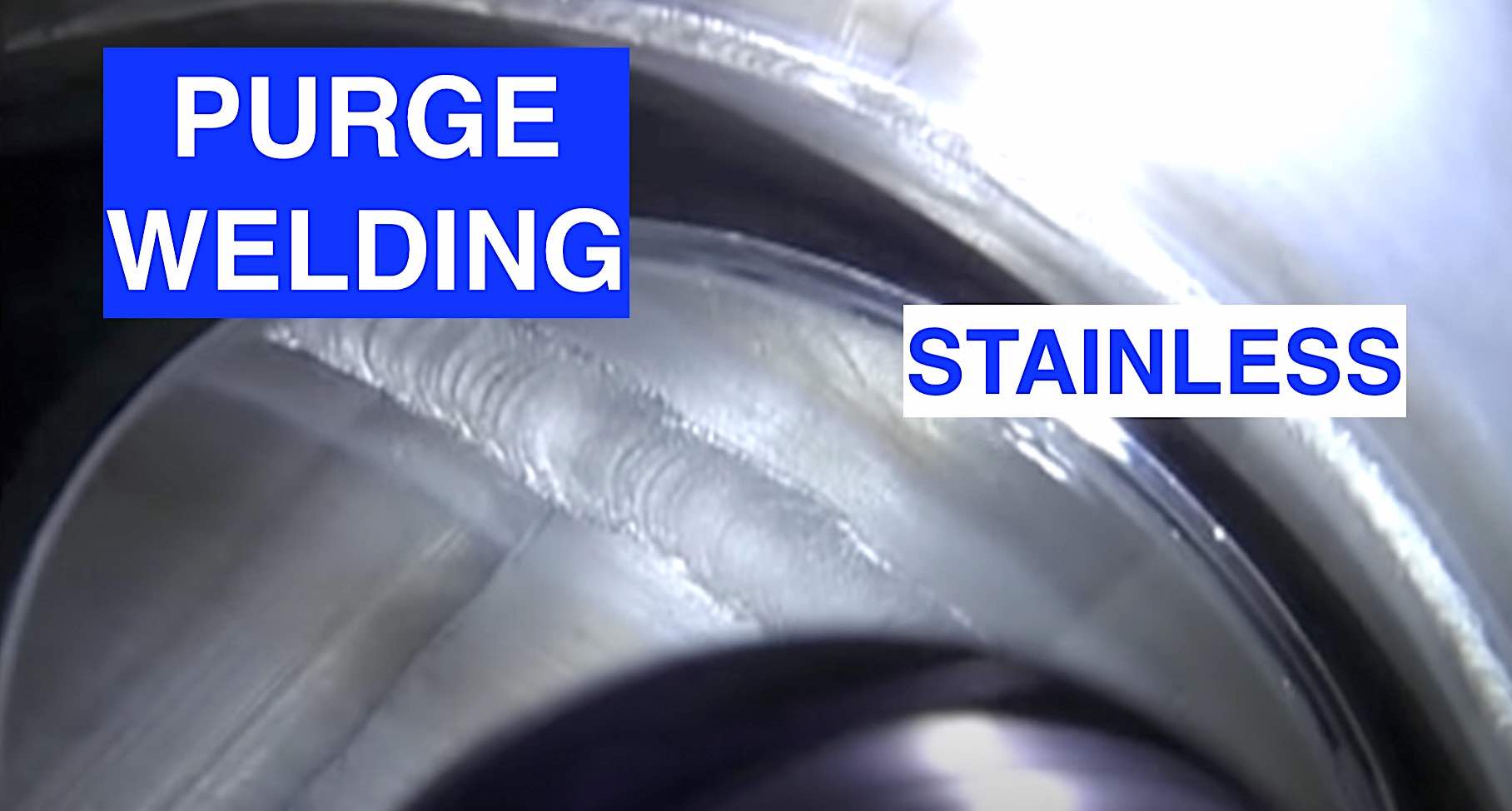

Tig Welding Stainless Steel Tubing with purge

Before we get too deep into welding stainless steel, if you read my web page on Welding carbon Steel , you may remember that plain carbon steel is basically Iron and Carbon with small amounts of other stuff like manganese.

Low Carbon Steel has .3 percent carbon. Not 3 percent but 0.3 percent or point 3 percent. That’s not much.

For comparison sake, Cast iron has a full 3 percent and sometimes more. That’s why cast iron is such a pain to weld and also why low carbon steel is the easiest metal to weld… low carbon steel is also the cheapest metal to buy.

Low Carbon Steel is what is most often uses in learning how to weld and low Carbon steel is what we compare all other metals to when we study metals.

Why? Well it’s easier to understand stuff if we can compare it to something we already know and understand.

Well now its time to compare something else to carbon steel.

Let’s compare stainless steel to carbon steel.

Stainless steel comes in several different varieties but the most common are 300 series stainless.

and the most common 300 series stainless is 304

The stainless properties of stainless steels are primarily due to the presence of chromium in quantities greater than roughly 12 weight percent.

stainless steels contain some combination of iron, chromium, and nickel as the main elements.

Most stainless steels are mostly iron. If your are familiar with the term 18-8 stainless that was widely used in the advertisement of stainless steel cookware, the 18-8 signifies 18 percent chromium and 8 percent nickel with the remainder being iron except for some small percentages manganese and other elements.

One thing I have to mention about welding stainless steel is that the back side of a fully penetrated weld needs argon shielding just as much as the front.

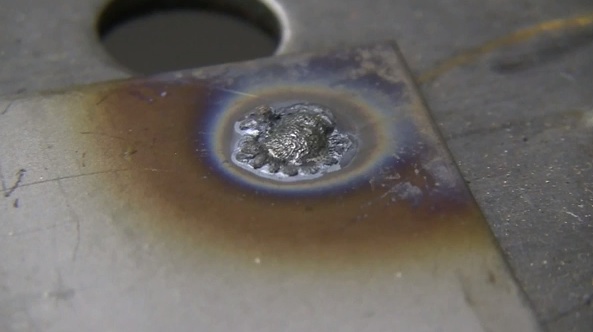

top portion purged...bottom no purge

If the penetration side is not shielded with argon, it will "sugar" which is a slang word for oxidize.

Granulation is another descriptive term that accurately describes what happens.

A closeup photo of the granulated or sugared stainless steel weld reveals why sugared welds fail in service. There are deep pits and crevices that are bound to develop into cracks.

"stainless loves argon!.. "

watch more tig welding stainless steel videos