TIG Weld Techniques, Ripple spacing, travel speed, and heat input

This video shows TIG Weld Techniques for tight and loose ripple spacing on an outside corner joint.

There is a common misconception that each ripple is a bead.

I guess that came to being due to beads on a necklace resembling a tig weld bead.

But a weld bead is a whole series of ripples....not just one.

Each

ripple is actually just a freeze line where filler rod is added and

momentarily changes the solidification...or a ripple can be caused by

pulsing the current if no filler is used.

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

Tight vs Loose Ripples

First off, neither one is necessarily better than the other.

Tight ripple spacing has a smoother surface. While loose ripple spacing tends to have more peaks and valleys.

But as you can see in the cross section test in the video, the peaks and valleys are not as drastic as they seem visually.

How TIG Weld Techniques affect travel speed

Travel speed has a big effect on heat input.

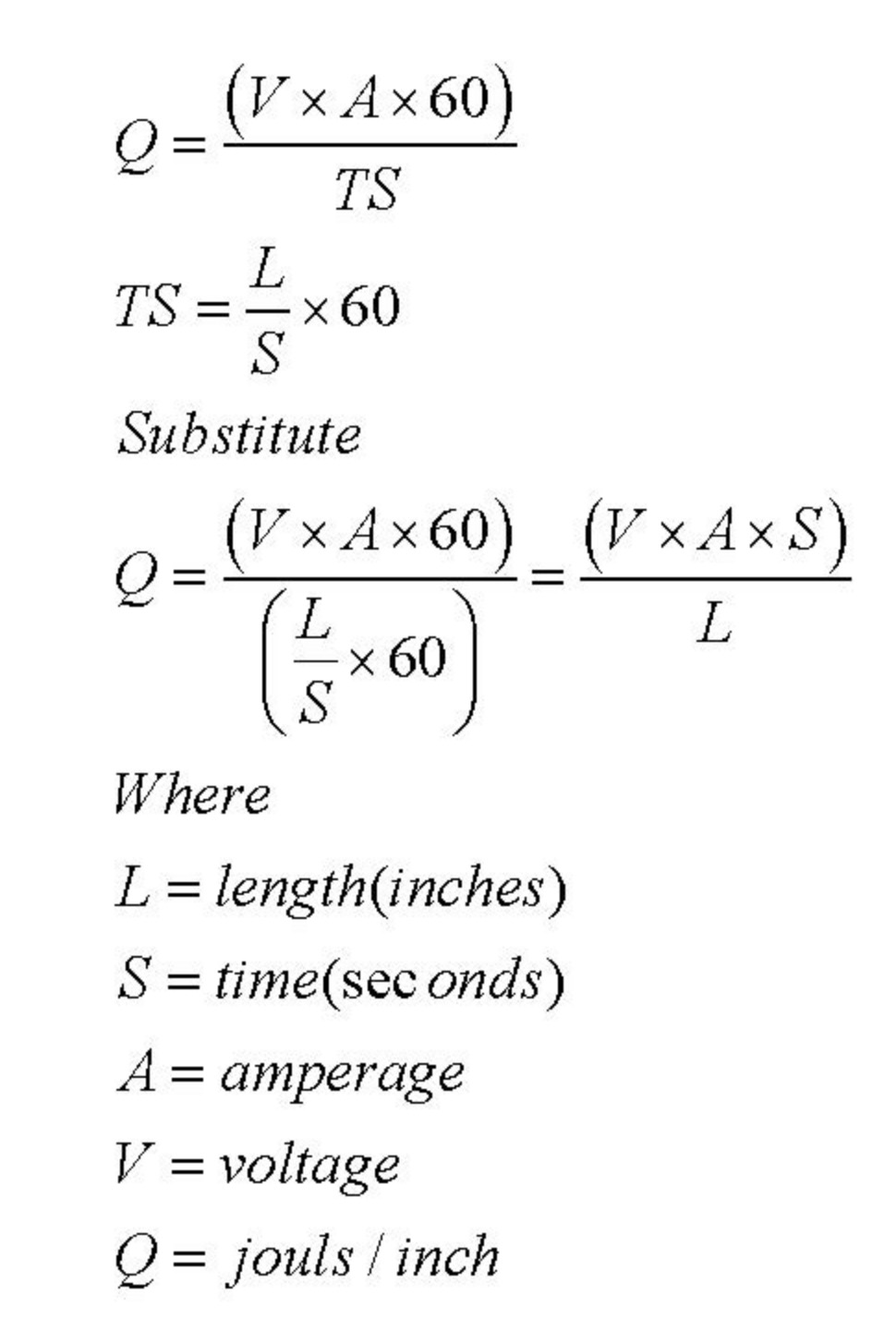

the formula for travel speed is something like this

Basically, heat input is calculated by multiplying voltage times amperage times 60 ...and then dividing that by travel speed.

So if travel speed is excessively slow in order to achieve a tight ripple spacing, then that might cause distortion, or even grain growth.

But if ripple spacing is so wide that the cross sectional thickness of the weld is too thin, then that is not good either.

That is why, I like to shoot for ripple spacing somewhere in between these 2 exaggerated examples.

In addition to that, with manual tig welding, sometimes my filler wire feeding hand struggles to keep up with my torch hand.

The rate at which I feed rod needs to be such that I have time to feed rod in between dabs.

I am still trying to get better at feeding rod, even after many years of doing it, I still have plenty of room for improvement.

I still think the best way to improve skill in feeding rod is to do it while you sit and relax in your favorite chair...or by doing what I call the

What is the Aluminum Drill?

The aluminum drill is a skill drill where you pad aluminum beads on a piece of scrap plate.

It provides a lot of wire feeding practice because with aluminum, you feed a lot more rod than you do with steel.