Overhead MIG Welding with Primeweld MIG 180

Overhead MIG welding refers to the process of using the MIG (Metal Inert Gas) welding technique to join metal components that are positioned in the overhead position.

In the overhead 4F position, the main challenges for short circuit mig welding are:

- Using settings that are almost as hot as for flat and horizontal

- using a short stickout less than 1/2" (stickout is the amount of unmelted wire extending past the contact tip)

- using minimal gun angle (this can be a slight push or pull angle..both work)

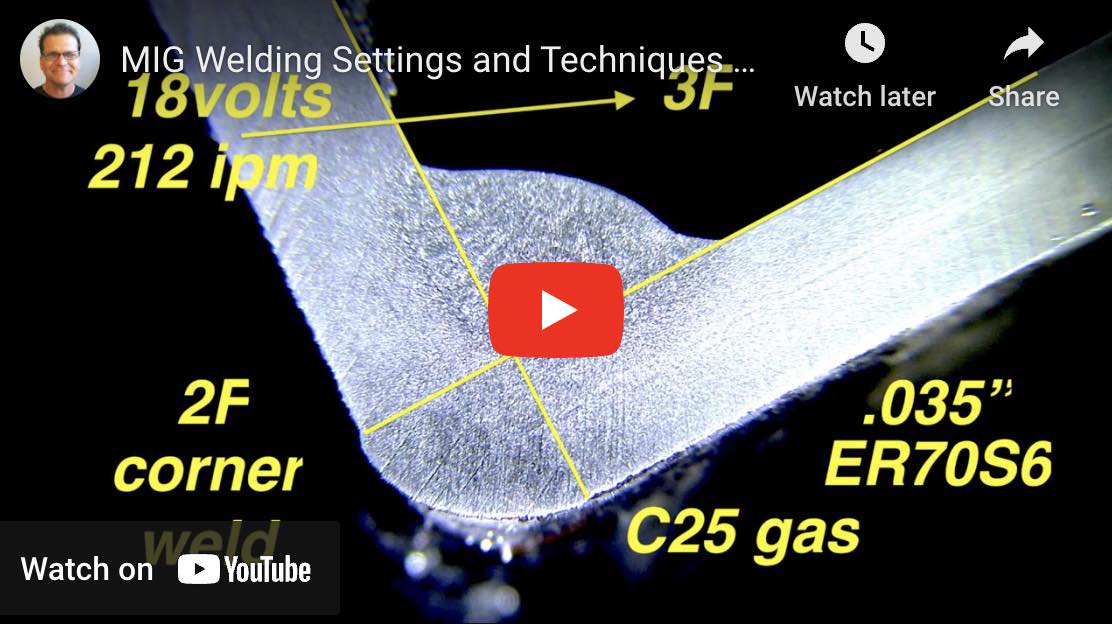

MIG welding, also known as Gas Metal Arc Welding (GMAW), utilizes a continuous consumable wire electrode and a shielding gas to protect the weld from atmospheric contamination. The wire electrode is fed through a mig welding gun, which also supplies the shielding gas.( for short circuit mig, this usually either 75argon/25co2 or straight co2.)

Welding in the overhead position presents unique challenges compared to other welding positions. Gravity affects the weld pool, making it more prone to sagging or crowning up, which can result in an overly convex weld bead along with other potential defects.

One of the main challenges with mig welding overhead requires the welder to maintain an uncomfortable and physically demanding position for an extended period. This often results in using a stickout distance that is too long.

And a long stickout actually reduces amperage and can cause a ropey bead.

To overcome these challenges, several considerations and techniques are employed during overhead MIG welding:

- Electrode angle: for an overhead fillet weld like a tee joint, The mig gun should be aimed at a slightly higher angle compared to other positions. This helps counteract the sagging effect of the weld pool and allows better control of the molten metal.

- Welding parameters: Settings should be similar to what work on flat and horizontal with slightly less wire speed. Don't be fooled into using really cold settings...you need some arc force to penetrated into the root and to help the bead flatten out..but remember to keep your stickout shorter than 1/2" for short circuit mig.

- Technique and travel speed: A slight manipulation of the arc can help the bead to flatten out and helps avoid excess convexity.

- Joint preparation: Hot rolled steel can have a thick layer of mill scale that can act as a barrier to penetration. Cleaning the mill scale works wonders for short circuit mig welding. Square tubing usually has a very light mill scale but thicker hot rolled plate can have a very thick layer. Use your own discretion but you cant go wrong by removing mill scale with short arc mig.

By using these techniques and following best practices, overhead MIG welding can almost as easy as welding on the workbench.

learn more about the MIG 180 at weldmonger.com

I think of my Mig180 mostly as a Great Little MIG Welder with a great arc and nice small mig gun that feels great in my hand... but it also Stick welds, and even comes with a spool gun for aluminum.

just look at all that comes with it... That is a lot of bang for the buck!