Vertical Uphill Welding Technique

For mig welding of ¼” and thicker steel, this vertical uphill welding technique penetrates way better than downhill welding.

WAY BETTER!!

No matter how hot you set the downhill, you cant penetrate as much as you can uphill.

ok, enough of stating the obvious...

The problem is that looks are important too and if you cant make a good looking uphill weld, its tempting to just weld downhill.

But what about being able to sleep at night? That’s important too.

There are really important welding jobs like work platforms, a hitch on an aircraft tug, lifting devices, aerial boom trucks and cranes, etc, where if the weld fails, someone will get hurt.

You need to have confidence that your welds are going to hold above all else. Its important that your welds look good, but its even more important that the welds don’t break.

Here is a little uphill welding technique that does both. It looks good, and its burns in deep.

I made this video recently using .035 e70s6 wire , short circuit mig welding with 75/25 argon/co2 , using a millermatic 251 set at 19 volts and about 250 ipm.

its 1/4" hot rolled 1010 steel ...not cleaned.

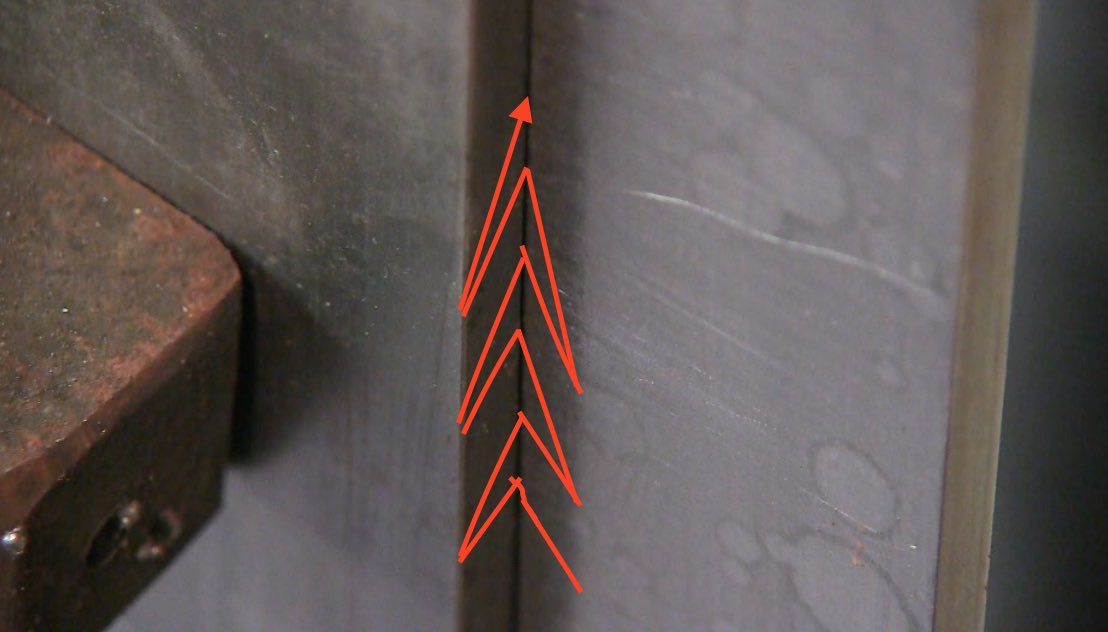

A couple of years ago , I put up a youtube welding video showing a slightly different uphill mig welding technique where an upside down V is used by going from side to side tracing the leading edge of the puddle in a series of upside down V’s.

The weld didn’t look all that great because I was maneuvering around a camera and tripod.

But it didn’t look that bad either. You would have thought it was the worst weld in the world by the way all the youtube douches came out of the woodwork to weigh in on how to do it better....At first it kind of pissed me off, but it got me thinking about a better technique for uphill mig.

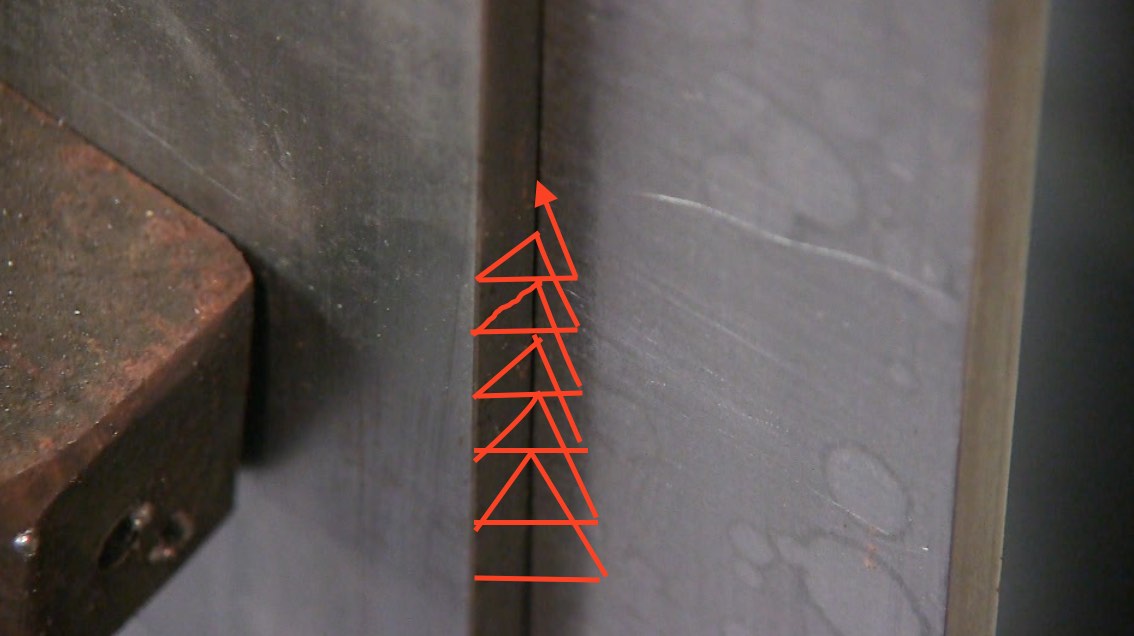

One of the uphill techniques suggested was some kind of Christmas tree welding technique. Anyway, it got me experimenting and I settled on this little uphill technique that is essentially a series of triangles.

I have tested a whole bunch of these joints…like hundreds.

Both the upside down V and triangle techniques work . Both techniques penetrate well into the corner of a joint when done right using a tight stickout with the right settings…

but the triangles almost always look better.

So that is my new favorite uphill welding technique.

Here is a hot tip…this welding technique also works for 6011, 6010, and 7018 uphill stick welding .

The videos should explain pretty well what is going on, so I will shut up and let you finish watching..

exit vertical uphill welding see more mig welding tips