Mild Steel TIG Welding Rods

- HOME

- TIG WELDING

- Mild Steel Tig Welding Rods

scroll down for videos

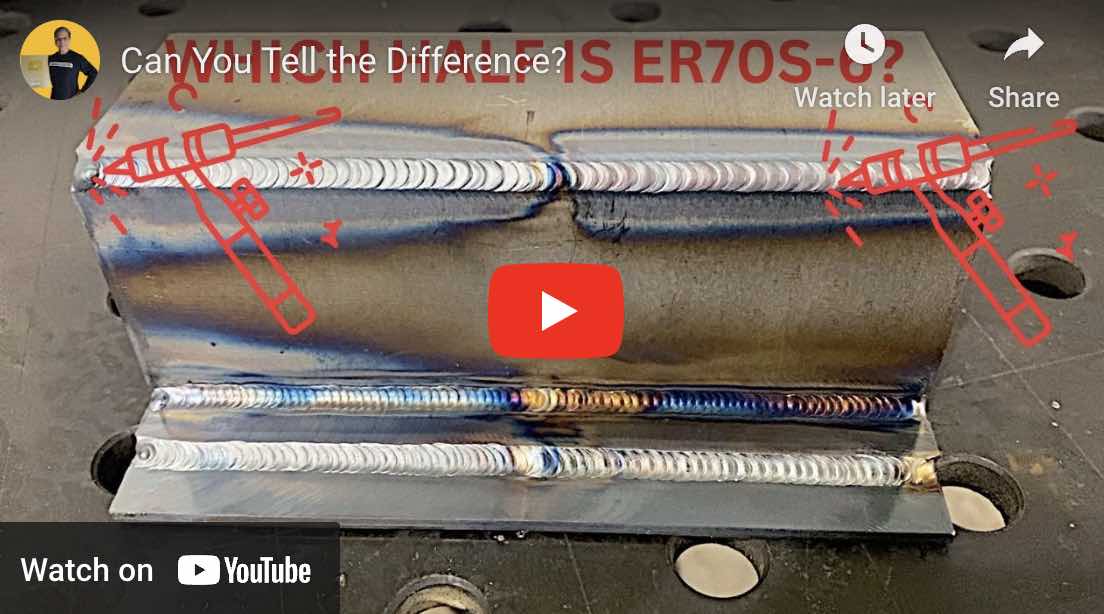

When it comes to mild steel tig welding rods, ER70S-6 and ER70S-2 are the two main choices.

ER70S-6 has more silicon content and typically has a slightly more fluid puddle. ER70S-6 mild steel tig welding rods excel at open root joints where the back side of the joint is exposed to air.

ER70S-2 is a triple de oxidized mild steel tig welding rod that is slightly less fluid than ER70S-6 but also contains additional deoxidizers like zirconium, titanium, and aluminum.

A note of caution: Gas welding rods like rg45 or rg60 often look just like mild steel tig welding rods but do not contain the same deoxidizer elements.

DON'T USE GAS WELDING RODS FOR TIG WELDING UNLESS YOU LIKE POROSITY AND CRAPPY LOOKING WELDS!

I Have answered numerous emails where gas welding rods used for TIG welding was the problem.

Mild steel TIG welding rods are cheap so why chance it?

TIG welding filler metal is in stock at Weldmonger.com

When a Welding Procedure is used, the filler metal will usually be specified.

When a procedure calls for ER70S-2, that is what you need to use ...even though ER70S-6 might work better.

When you are the one selecting the mild steel tig welding rods, ER70S-6 might be your choice.

For a lot of applications, the 2 rods weld almost identical.

It takes experience to know where one excels over the other.

The differences are subtle.

Some swear by ER70S-2 for welding vertical uphill or for filling gaps.

Others love the way ER70S-6 flows on 4130 chromoly.