How to Mig Weld Vertically uphill using short circuit mig

Scroll down for videos

How to mig weld vertically using the primeweld mig180

Watch the latest videos here

How to mig weld vertically using the Miller Mulitmatic 220 ac dc

Key factors for How to mig weld vertically

- use lower voltage and wire speed than you would use normally for flat welding

- use a short stickout even if that requires you buy a different nozzle and contact tip ...or to trim the nozzle

- limit gun angle ( if you aim for dead nuts 90 degrees you will most likely have a slight upward push angle.

- use a technique that plays the arc on the leading edge of the puddle like either an upside down V ...or series of triangles.

Mig welding uphill on a 5F tube to plate. MIG welding vertically on Tube to Plate

A 5F tube to plate weld test is sometimes used to qualify for fillet welds like socket welds.

A 5F test usually qualifies for all positions depending on the welding code.

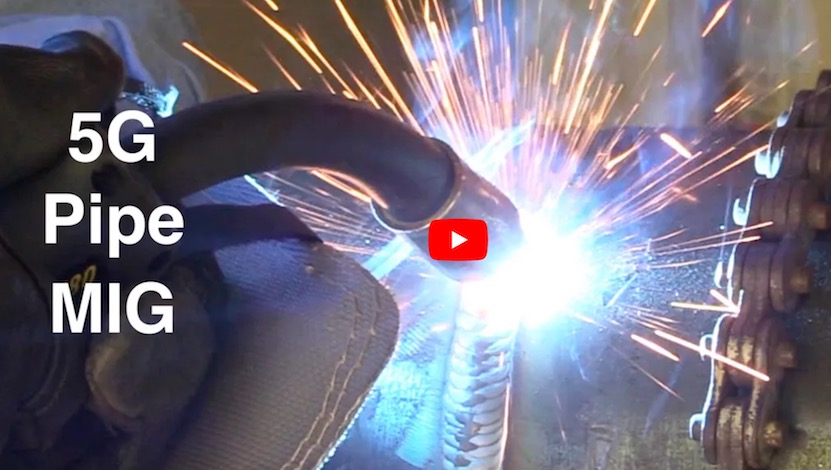

Mig welding a 5G pipe downhill open root...Uphill fill and cap

Some procedures allow for a downhill root for open root pipe or plate.

With a gap, a downhill root works

Downhill short circuit mig welding on anything thicker than 1/8" can easily result in lack of fusion.

With short circuit mig, open roots work very well with either downhill or uphill mig provided correct techniques and settings are used.

Pipe shops often use procedures with downhill root and then switch to uphill fill and cap.

Tuning Voltage and Wire Speed for Vertical Uphill Short Circuit MIG Welding

Welding vertical uphill (3G) with short circuit MIG is tricky because gravity works against you. To get good penetration, fusion, and a consistent bead profile, you need to fine-tune voltage and wire speed carefully

1. Voltage Settings – Lower than Flat or Horizontal Welding

Why?

- Too much voltage = excessive heat, causing the weld puddle to become too fluid and drip.

- Too little voltage = poor penetration and lack of fusion because the arc is too cold.

How to Adjust:

✅ Use lower voltage than flat/horizontal welding.

✅ Typical voltage range: 17V to 20V (depends on wire size and material thickness).

✅ Start lower and increase slightly if the arc feels unstable.

2. Wire Speed Settings – Balanced for Control and Fusion

Why?

- Too fast wire speed = excessive buildup, causing excess convexity

- Too slow = not enough punch...lack of fusion and an unstable arc.

How to Adjust:

✅ Use a moderate wire speed (lower than flat/horizontal welding).

✅ Typical range: Depends on thickness and wire diameter. But often times you can use mig chart settings for one or two lower thickness.

✅ If the arc stubs into the puddle, increase voltage or decrease wire speed slightly.

✅ If the arc is too long or erratic, decrease voltage or increase wire speed slightly.

3. Additional Tips for Vertical Uphill MIG Welding

✔ Use a Short Stickout (⅜” to ½”) – Too long = inconsistent arc & spatter.

✔ Use a a technique that keeps the arc on the leading edge of the puddle (upside down V or Triangle Motion) – Helps with good penetration

✔ use a slight push Angle (~10° Upward)

✔ Use the Right Shielding Gas (75/25 Ar-CO₂ for short circuit mig) – Provides a stable arc and good penetration.