3g Mig Welding Certification Test tips

scroll down for complete video

Before we get too deep into 3g mig welding test techniques...

A word about short circuit mig.

Short circuit mig is properly called GMAW-S.

GMAW stands for gas metal arc welding - and the s is for short circuit.

The term "short circuit" indicates the way the metal melts into the puddle....many times per second, the wire actually short circuits into the puddle before arcing back and then short circuiting again.

Most structural welding is done using flux core (fcaw), stick (smaw), or even gmaw spray transfer. ( also called spray mig)

Thats because short circuit mig requires contractors to perform extra procedure qualification tests while smaw and fcaw allow for using pre-qualified procedures.

Qualifying your own weld procedures involves many more tests than qualifying a person.

Its complicated, but the simple reason all the extra tests are required because short circuit mig is the most likely process to cause cold lap.

Short circuit mig is used for pipe welding more than for structural and in preparation for pipe welding, it makes sense to weld plate first because its easier and cheaper, and it is good practice especially when using the same bevel, gap, land, etc. because the exact same settings work.

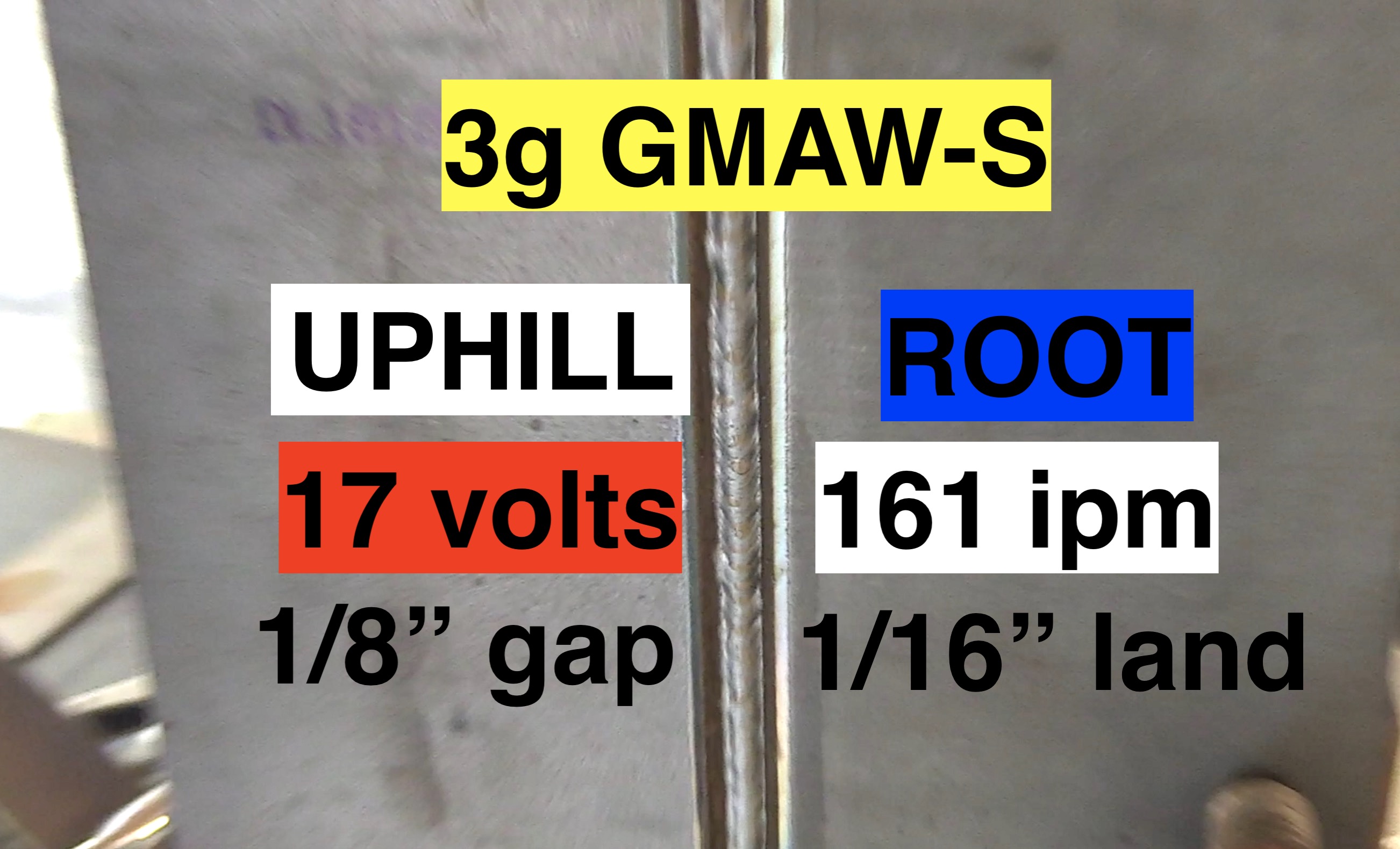

A common Mig welding certification test is a 3g Mig along with a 4g Mig on 3/8" thick plate.

This video is about the 3g mig welding certification test...

the 4g overhead plate test is here.

When a 3g vertical and 4g overhead plate are done together, all positions are qualified according to most AWS codes...thats a lot of bang for the buck.

2 plate test welds and you get qualified for flat, horizontal, vertical, and overhead positions.

So...Here are some tips for passing a 3g mig plate test...

• Clean the mill scale to 1/2" away from the weld...clean to bright shiny metal. (in the real world, you might not clean as much, but for a test, it helps)

• grind or file a 1/16" land on the bevels ( some prefer no land at all)

• gap the pieces 1/8" plus or minus 1/32"

• mig machine ( millermatic 250) settings go something like this...

• 19 volts , 245 ipm, 25 cfh of argon/co2 75/25

• 245 ipm wire feed speed ( turned it up to around 275 ipm for second pass)

• Make the tack welds large enough so that when you light up on the tack, you dont lose the gap.

• Stay on leading edge of puddle for all passes.

• Second pass technique is to "trace" the leading edge of the puddle.

• Second pass should be 1/16" below flush in order for the cover pass to go in well.

• let cool before cover pass

• Cover pass should be equal to or less than 1/8" above flush.

- HOME

- MIG WELDING

- 3g Mig

Differences in Short Circuit, spray , and globular transfer in GMAW.

Gas Metal Arc Welding (GMAW), also known as Metal Inert Gas (MIG) welding, offers various modes of metal transfer, including short circuit transfer, spray transfer, and globular transfer. These modes differ in terms of the electrical and physical characteristics of the welding process. Here's a brief explanation of each mode:

- Short Circuit Transfer: In short circuit transfer, the welding wire comes into contact with the base metal, creating a short circuit. The current flowing through the wire melts the wire tip, forming a small molten droplet. The short circuiting action causes the droplet to detach from the wire and transfer across the arc to the weld pool. This mode is characterized by low current and voltage settings and is commonly used for welding thin materials or in positional welding. The most common shielding gas for short circuit mig is called c25 (75/25 argon/co2) but pure Co2 can also be used.

- Spray Transfer: Spray transfer occurs when the welding current and voltage are higher than in short circuit transfer. In this mode, the welding wire does not make direct contact with the base metal but is continuously fed into the arc. The current melts the wire, producing a fine spray of molten droplets that are propelled across the arc to the weld pool. Spray transfer is ideal for welding thicker materials and offers higher deposition rates and better penetration than short circuit transfer. Spray transfer mig is limited a bit in that it is too hot for vertical uphill and sometimes difficult for certain overhead joints. Spray transfer mig requires different gas. There are several shielding gases that work but 90/10 90 argon/10 Co2 is fairly versatile and can also work with pulse spray mig.

- Globular Transfer: Globular transfer is characterized by larger molten droplets that form at the wire tip but do not detach as consistently as in spray transfer. The droplets are transferred to the weld pool through a combination of gravity and electromagnetic forces. Globular transfer typically occurs at moderate current and voltage settings and is commonly used for welding thicker materials, though it may result in more spatter compared to spray transfer. There are actually procedures that specify globular transfer but often times, it is just an accident and from poor settings.

It's important to note that in the case of a coded weld, the welding procedure will specify the mode of transfer.

Otherwise the choice of transfer mode depends on factors such as material thickness, joint configuration, welding position, desired weld quality, and the specific requirements of the welding application. Welding parameters such as shielding gas mix, current, voltage, and wire feed speed can be adjusted to optimize the transfer mode and achieve the desired welding results.