2G Aerospace Weld test group 1 practice tips

The AWS D17.1 welding specification, officially known as "Specification for Fusion Welding for Aerospace Applications," is a standard developed by the American Welding Society (AWS) specifically for welding in aerospace applications. It provides guidelines and requirements for the welding of materials used in the aerospace industry, including aircraft, spacecraft, Ground Equipment, and related components.

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

Here are some key aspects and uses of the D17.1 welding specification:

- Aerospace Industry: D17.1 is primarily used in the aerospace industry to ensure the quality and reliability of welded joints in aircraft and aerospace systems. This specification helps maintain the structural integrity and safety of aerospace components, as welding is a critical process in their fabrication.

- Materials: It covers a wide range of materials commonly used in aerospace applications, including various types of metals and alloys such as carbon and low alloy steels, iron based stainless steels, nickel alloys, aluminum, magnesium, titanium, cobalt, and other exotic alloys like niobium. The specification provides specific requirements for welding these materials as well as welder qualification.

- Welding Processes: D17.1 provides guidance on various welding processes, including gas tungsten arc welding, plasma welding, and other fusion processes. D17.1 outlines the basic procedures and criteria for each welding process and also leaves quite a lot of responsibility on the engineering authorities at each facility.

- Quality Control: The specification includes quality control and inspection requirements to verify that welding processes and welds conform to specified standards. This involves criteria for welder qualification, welder performance, non-destructive testing, and visual inspection.

- Industry Compliance: Compliance with D17.1 is often required by aerospace regulatory bodies, manufacturers, and contractors to ensure that welding processes and products meet the stringent requirements of the aerospace and aviation industry. Adhering to this standard helps ensure product reliability and airworthiness.

Why a 2g weld test?

Many aerospace companies choose to strictly use a 1g flat position test because they have parts positioners and manipulators that can put every weld flat.

Other companies use a 2g and 3g test to provide a wider range of qualifications.

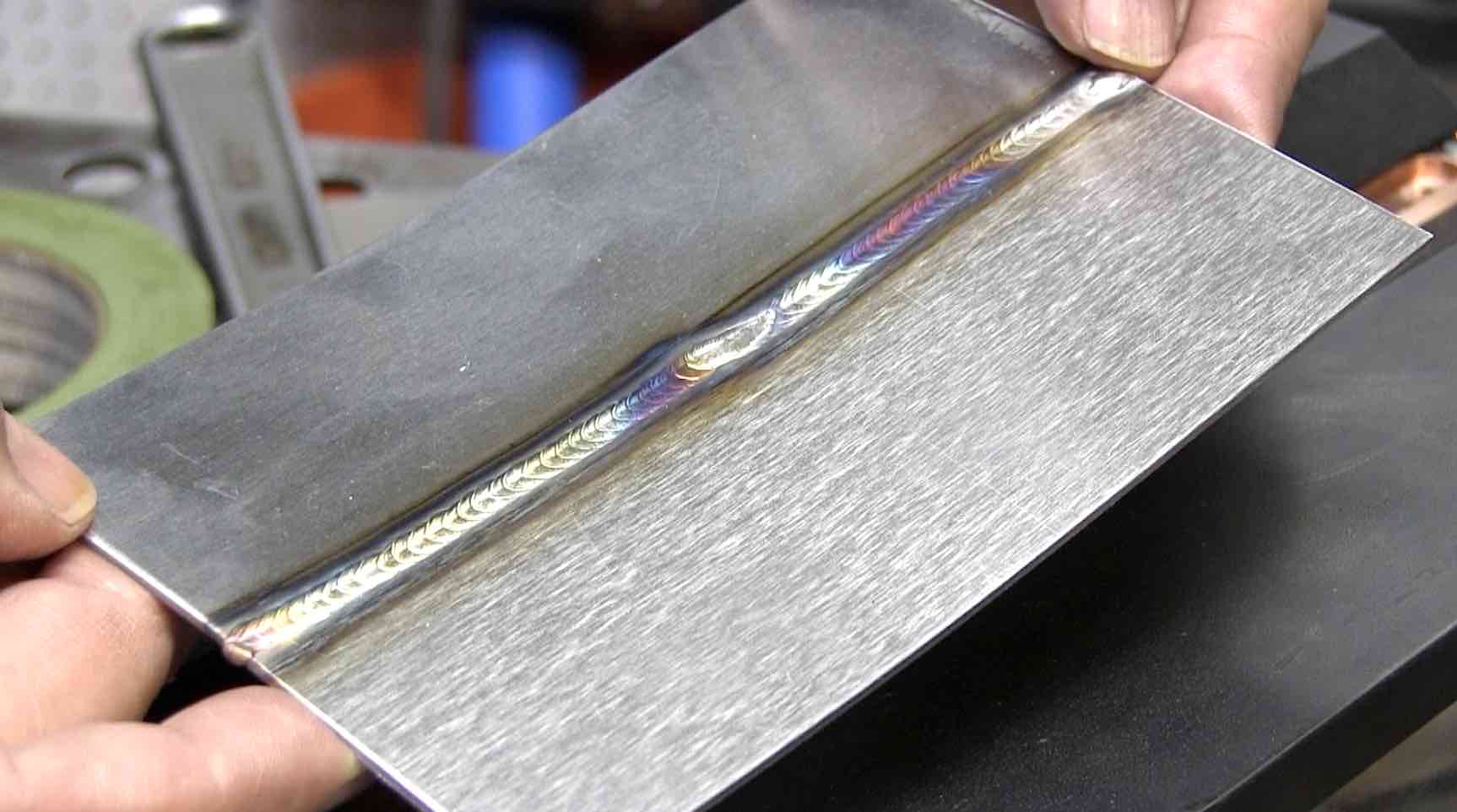

This page is about practicing in the 2g position using plain cold rolled steel before moving on to more expensive metals like 17-7ph stainless, or Inconel 718.

Cold rolled steel provides good practice, is readily available, and its cheap.

I recommend something in the .040" (1mm) thickness range at first.

Once you are consistently making good visually acceptable welds on .040", try going thinner to around .030"

This simple practice will go a long way in teaching you about how to set up the test pieces in the fixture, how much backing gas to use, amperage needed, size filler wire that works best, and a whole lot of other little details.

I used a ceramic jazzy10 cup for this weld and I think its a great choice for aerospace weld tests on carbon and low alloy, iron based stainless steels, nickel alloys, and cobalt based alloys.