Aerospace Welding Tests with Tips, Settings, arc shots in simple short videos

scroll down for Aerospace Weld Test videos

Basic Stainless 1G aerospace welding test per D17.1 specs

go to main weld test page with videos on 6g pipe welding tests as well as 3g and 4g plate tests

Most Aerospace weld tests are done using some type of purge fixture.

If you have never taken a weld test like this, the video above will give you some good tips for how to position the pieces in the fixture, amperage and purge flow settings, along with clear arc shots and tips.

Basic Stainless 2f Tee joint aerospace welding test per D17.1 specs

The tee joint in 2F position can be a difficult weld test.

The goal on this aerospace welding test is to achieve penetration into the root of the joint without melting through.

The AWS D17.1 specification provides some tolerance for melt thru but weld test supervisors all interpret it differently.

A lot of inspectors don't want to see any melt thru at all on thicknesses .063" and under

Aerospace Welding Test practice Tips

2g aerospace welding test practice using Carbon steel

The Aerospace alloys most often used for weld certification tests are:

- 4130 chromoly

- 17-7 ph stainless ( ph stands for precipitation hardening)

- Inconel 718

- 6061 aluminum

- Az31B Magnesium

- 6AL4V Titanium

- Haynes 188 or L605

Some of these alloys are extremely expensive so it makes sense to get some practice on plain carbon steel before attempting to weld on the more expensive alloys listed.

Carbon steel is cheap practice metal but still provides good practice for aerospace welding tests.

Tips for passing a 1G aluminum aerospace welding test

Cleaning the sheared edge on butt joints is one of the most important steps in passing an aluminum aerospace weld test.

go to main weld test page with videos on 6g pipe welding tests as well as 3g and 4g plate tests

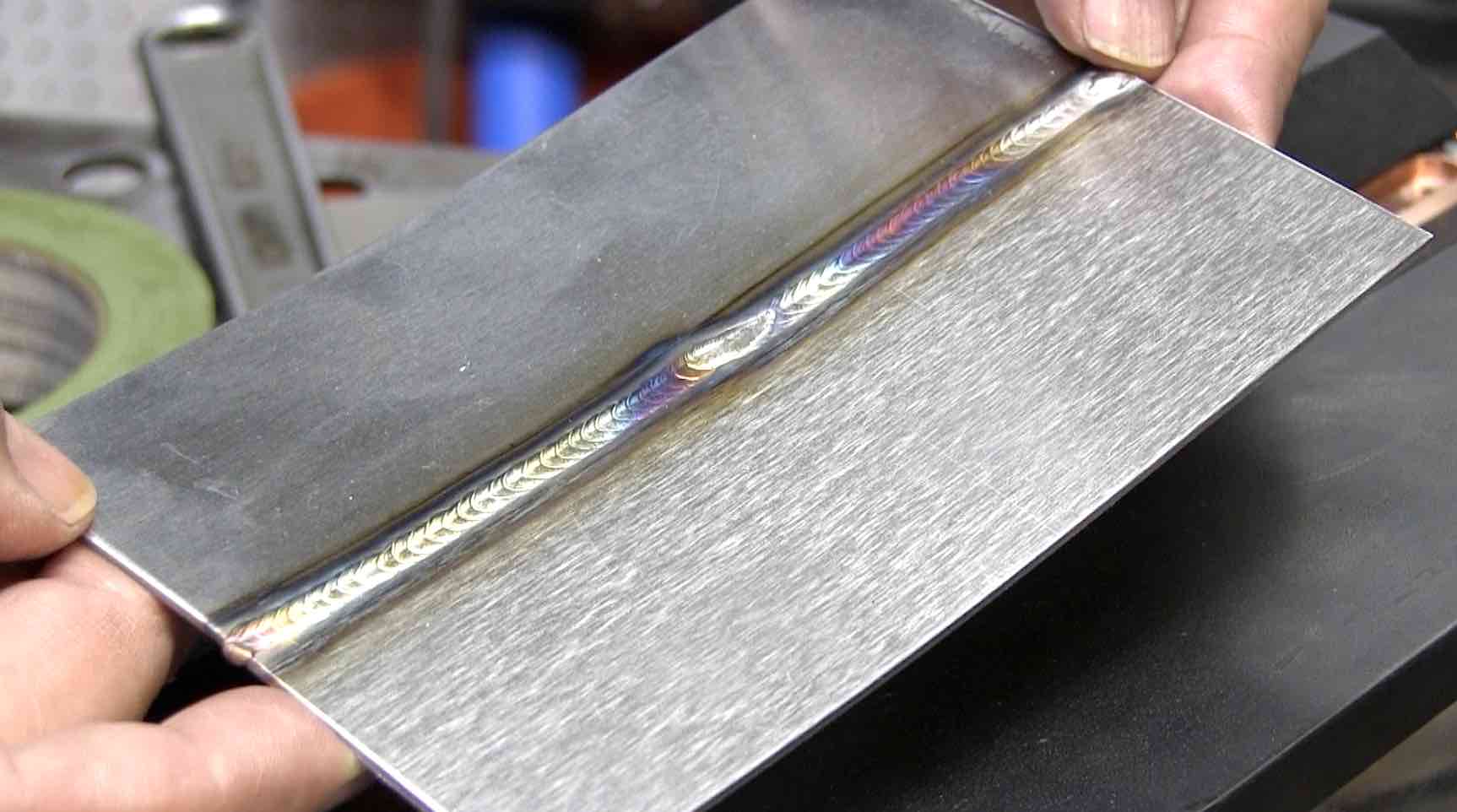

1G Titanium Aerospace Welding Test

Cleaning and Gas shielding are 2 very important parts of the welding process when welding titanium.

In some ways titanium is just as easy to weld as stainless steel provided proper gas shielding and cleaning is done.

But a titanium puddle can be very sticky.

The filler metal tends to stick to the base metal right near the fusion line.

That requires special wire feeding techniques.