Titanium Welding

IF you are new to titanium welding, I believe this page will be a great help to you.

See main page on welding titanium

Scroll Down for Videos on Titanium Welding

What are the 3 Biggest Mistakes in Titanium Welding?

You might think the #1 biggest mistake in titanium welding is failing to clean or purge with argon.

Both these are important but the biggest mistake you can make is accidentally using the wrong rod.

Get the Best Gear for TIG welding Titanium

Weldmonger® dual flowmeter with lifetime warranty

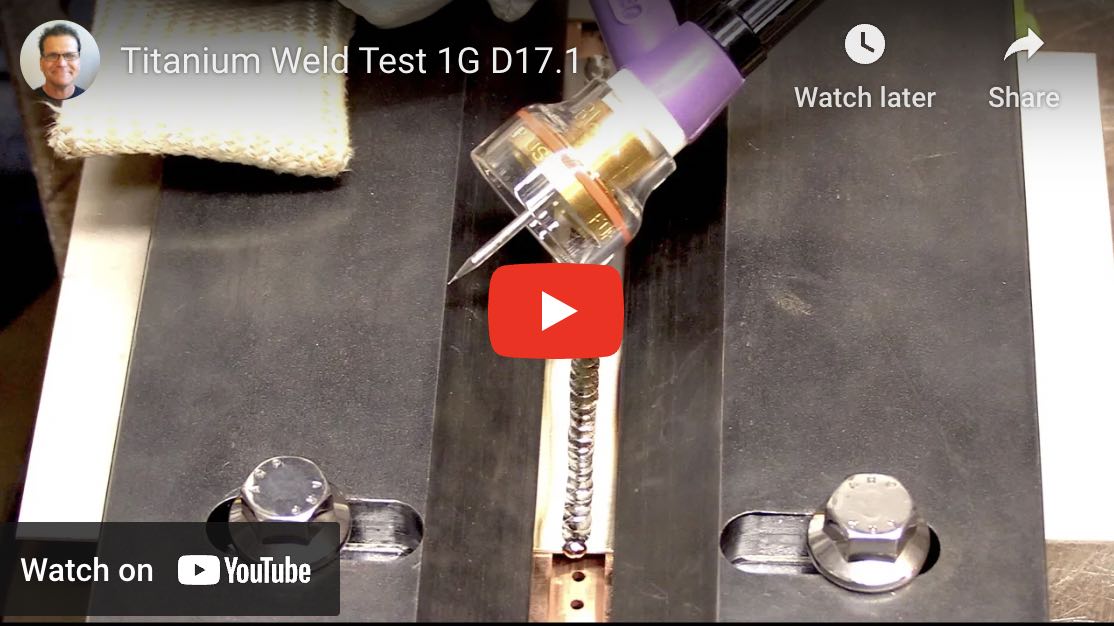

1G titanium weld test - based on AWS D17.1 aerospace specs

A 1G weld test in the .020" -.063" thickness range on 6AL4V titanium is a very common test for aerospace welding.

.040" thickness is very commonly used to titanium welding tests like this.

2G Titanium Weld Test Based on AWS D17.1 aerospace specs

Cleaning the edge before welding is key to passing any titanium welding test.

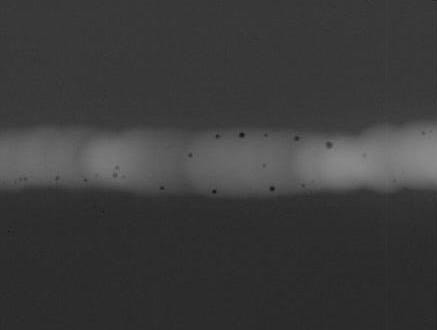

A 2G test is more likely to show porosity on X ray than other positions so clean those edges thoroughly before welding.

The main cause for failure on a titanium weld test is porosity and porosity is mostly caused by some type of contamination like oil or embedded grit from a sanding disc.

the x ray negative below shows scattered porosity in a titanium weld.

3G Titanium Weld Test Based on AWS D17.1 aerospace specs

3G is the vertical position. Getting comfortable is the key to passing a 3G titanium welding test.

Titanium Welding on a Bike Frame with Mike Zancanoto

Mike Zanconato walks us thru putting together a titanium bike frame and talks abot cleaning, purging, and argon shielding.

Best practices for Titanium Welding

- wipe titanium with acetone first to remove any residual oils or shop dust

- brand new clean titanium might only require degreasing, wire brushing, and deburring before welding. Make sure to use clean stainless steel brushes that are dedicated to titanium use only.

- If abrasives are needed, make sure they are fine grit and dedicated to titanium use only

- Purge the back side of any area that might exceed 1100F

Use a large size gas lens cup like a Furick BBW or MK14 or Cippy BBW to get great argon shielding on titanium.