7 Tips for TIG welding Aluminum

(okay maybe 8)

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Tips for Tig Welding Aluminum

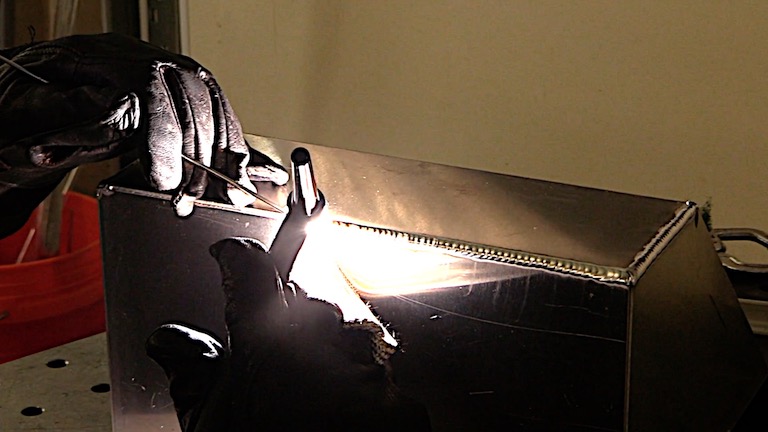

TIG Welding Aluminum

1. Get your AC Balance setting tuned right to get a clean puddle

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Tips for Tig Welding Aluminum

A simple turn of the AC balance knob can make a huge difference. The positive side of the alternating current is where you get cleaning from and the AC balance control adjusts the level of cleaning action you get from the arc by letting you adjust the percentage of electrode positive.

Learn more about this affordable tig welder with bonus kit at weldmonger.com

2. Aluminum has a property called "hot shortness". Here is a hack to prevent a tack weld from popping loose

Unlike steel which gets ductile when heated, Aluminum gets weak and brittle.

That is why small aluminum tack welds so often crack.

A small inboard tack can prevent the end tack from breaking when welding from an end on aluminum.

3. Avoid Wide Spaced ripples on thin aluminum

Making big widely spaced ripples on thinner aluminum can cause problems..especially if there is any gap at all…frequent dabs of filler rod at frequent spacing helps prevent opening up a hole on thin aluminum.

4. Enjoy the benefits of the AC Frequency Setting

High AC frequency settings of 200hz and higer might be annoying to listen to but can really help to focus the arc and make it stable….But your TIG welding machine needs to have enough amperage to handle the higher frequency settings because high frequency settings require more amperage.

5. Rule of 33 for Pulse settings

The rule of 33 can be a big help on thin steels. The rule of 33 simply means using 33 for all the pulse settings. 33 pps, 33% background, 33% peak pulse. You can use the rule of 33 on aluminum if your tig welder does not have a low enough amp start for tig welding thin aluminum.

33 pulses per second is fast enough that it is easy to watch without eye fatigue and also agitates the puddle and allows it to flow better in some situations.

Primeweld TIG325x Videos

I like the digital readout feature on the primeweld tig 325x. It makes setting pulse rates easier.

water cooled package shown below with ck 20 torch

6. Lower AC Frequency settings can help sometimes too

Thick open corner joints that need a wide bead can benefit from a low AC frequency setting as low as 50hz…especially if you are pushing the upper limits on tig welder.

7. What if you just want to "Set it and forget it" on the AC frequency?

120hz is a great all around AC frequency setting if you just want to set it and forget it.

The Miller Diversion TIG has a fixed AC freqency setting of around 120hz because the designers at Miller decided that was a great all around setting for AC frequency.

There is nothing magic about 120hz. It's just a good all around setting for AC freqency

I prefer to be able to adjust AC frequency for each application but sometimes it doesn't seem to matter a lot.

There are lot more tips for TIG welding aluminum here along with videos.

Dont miss a single video by signing up for our newsletter here.