TIG Welding Mild Steel

3 of the Best Videos you will find on TIG Welding Mild Steel

Video #1 is a Better Way to learn to TIG weld mild steel by alternating beads of aluminum and mild steel

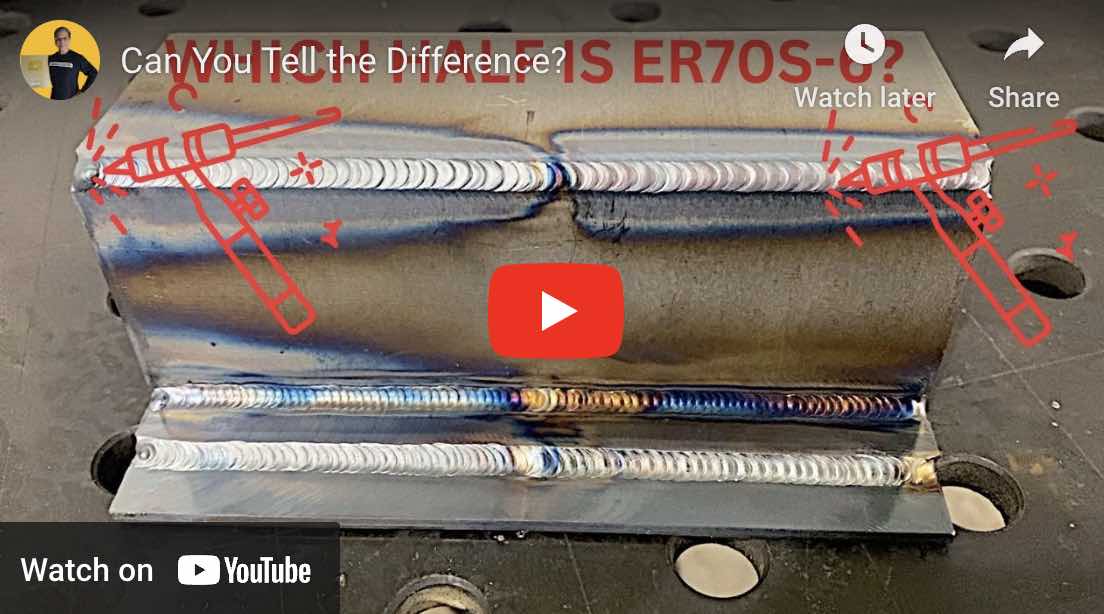

Video #2 Shows a Corner Joint, Lap Joint, and Tee Joint on 11ga mild steel using both ER70S-2 AND ER70S-6

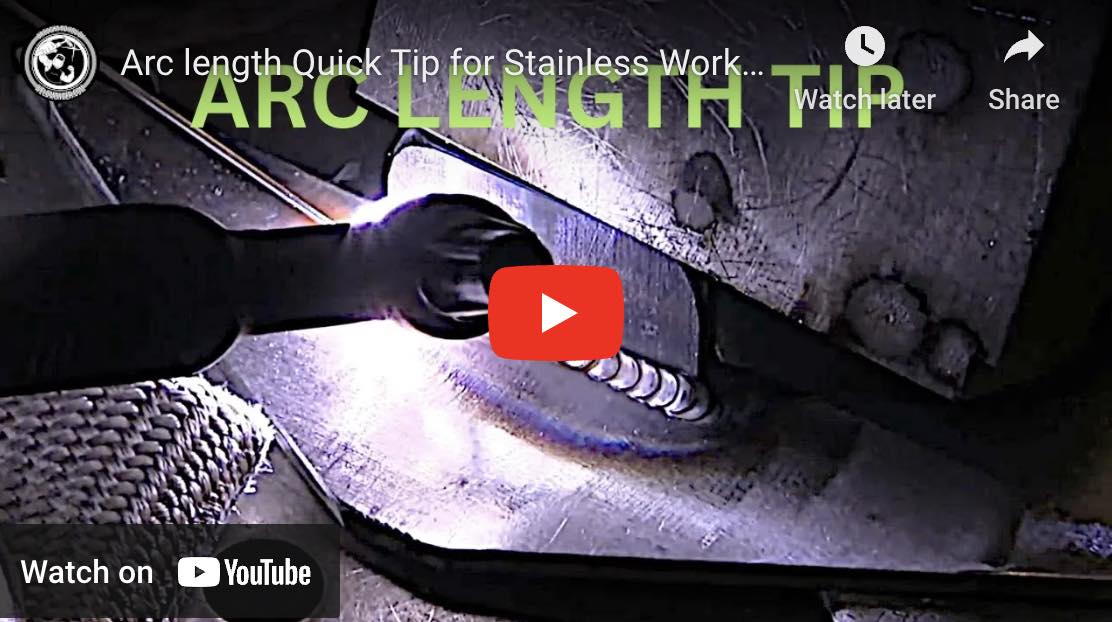

Video #3 Shows the importance of cleaning mill scale before tig welding mild steel along with tips for welding stainless, aluminum, and other alloys.

Mild Steel is another term for low carbon steel.

It is easy to work with. Easy to weld, easy to bend, drill, grind, shape, etc.

Mild Steel does not crack easily and does not harden much when heated and quick cooled

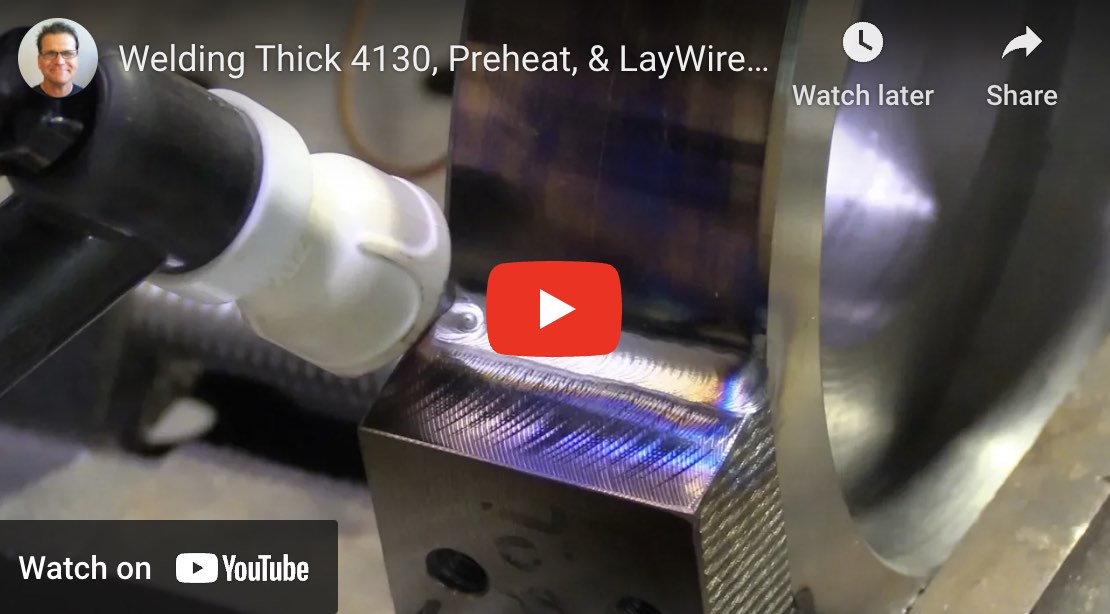

High Strength Steels and 4130 chromoly have higher carbon content and other elements that make them more likely to harden during the welding process.

Depending on the thickness, a preheat is often used on high strength steels and 4130 chromoly to slow the cooling rate and prevent hardening.