TIG Welding Aluminum with a Gas lens

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- tig welding aluminum gas lens

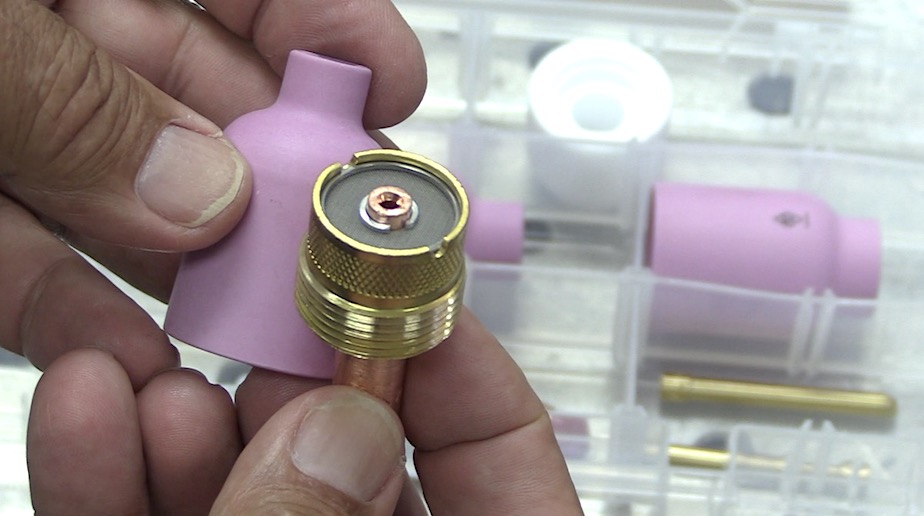

This page is about tig welding aluminum with a gas lens kit and #6 cup.

I don't always use a gas lens on aluminum.

In fact there are many situations where a standard #5 cup and collet body work just fine. Sometimes even better than a gas lens,

But for the particular weld in this video, I was using an air cooled 17 style torch.

Its

a good all around torch for me and can handle 200 amps for brief weld

but, it can get pretty hot at 175-200 amps if you weld very long at

all.

So I decided to use a gas lens setup because the extra mass you get with a large diameter gas lens collet body helps keep the torch cooler...at least a little bit.

A 17 style air cooled torch is typically rated at 150

amps but I often go higher than that for short periods without a

problem.

If I were to get an order for 100 of these parts, I would definitely go with a water cooled torch.

The

weld is a solid aluminum plug welded on the inside diameter of piece of

1/4” wall thickness 2” diameter tube to form a corner joint.

I used 4043 3/32" filler rod.

On a corner joint like this sometimes the main objective is to wrap the corners with the edge of the bead in a single pass.

That is why I rounded the tip of the tungsten and set my amperage to 200 and used a foot pedal to control my amperage.

I used all 200 amps at first but quickly let off to 175-185 amps once the part heated up.

I used a rounded 2% lanthanated tungsten electrode because it has a very high amperage limit.

When

I am in the upper limit amperage for a 3/32" tungsten, rounding the tip

seems to help maintain the same shape from start to finish and also

helps to fan out the arc cone to wrap the corners on the joint.d

An outside corner on 1/8” aluminum does not require a super wide bead so I only slightly rounded the tip of the electrode for better arc starts and a bit more control.

A tee joint is a different story. Getting penetration all the way into the root of the joint can be a challenge.

So for the tee joint filet weld, I just left the tip tapered and allowed it to round off on its own.

Here are a few takeaways to remember about tig welding aluminum with a gas lens

- I did three different joints and different thicknesses of aluminum and I used the same 3/32” 2% lanthanated electrode for everything.

- I could have used a larger electrode for the first joint that was thicker but I don’t really like to switch electrodes unless I really need to so just rounding the tip did the job.

- I also could have just welded all three joints with the same rounded tip but in my opinion it just worked better to tailor the tip for each joint.

- I also want to point out that I used a slightly longer electrode stick out than I would normally… strictly for filming so we can all see the puddle better.

- I showed a subtle technique where I lengthen the arc a bit while I am adding filler metal because puddle height usually grows a bit every time you add filler rod.

- Lengthening the arc a bit while you add filler helps avoid taking the tip for a swim in the puddle.

What is the difference between gas lens and collet body aluminum?

What is the difference between gas lens and collet body aluminum?

A gas lens uses several layers of fine screen diffusers to provide a non turbulent flow of shielding gas. A collet body uses simple port holes.

For some aluminum applications, a collet body works fine but a gas lens allows for longer tungsten stick out and better gas coverage.

Why use a gas lens for TIG welding?

Why use a gas lens for TIG welding?

Being able to use a longer stick out while maintaining good gas coverage is necessary for certain situations and for certain metals.

Stainless steels, nickel alloys, chromoly, tool steels, and titanium all require more gas shielding than plain carbon steel and a gas lens helps achieve that.

Is a gas lens better for tig welding?

Is a gas lens better for tig welding?

Not always. there are certain situations where a collet body will suffice.

And for those rare situations where galvanized coatings can't be completely removed, a gas lens will just get messed up.

But a gas lens will give usually provide better results across the board.