Tig Welding Aluminum Test - Tips for cleaning

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Tig Welding Aluminum

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

see more videos on tig welding aluminum

do the aluminum drill - getting the best aluminum practice

affects of frequency for tig welding aluminum

What is the most important thing to do for preparing a 1G aluminum Butt joint test weld...that will be x rayed?

You will see in the video but let me explain it here also.

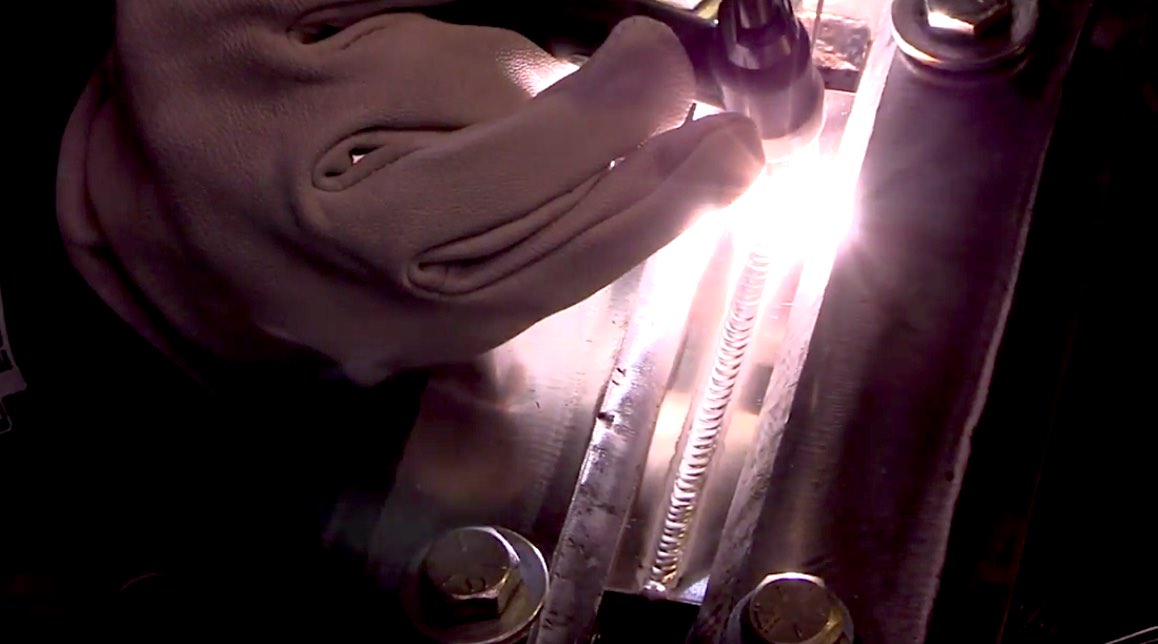

This video demonstrates the need for cleaning aluminum for test welds and for critical applications or when the weld will be x rayed.

Yes, it will help to wire brush the aluminum to remove oxide.

Yest it will help to wipe with acetone

Wait for it.....

Cleaning the sheared edge of a test piece makes more difference than any other single thing.

The sheared edge of a piece of aluminum sheet metal is rough with lots of embedded oxides.

unless you remove those oxides, they can create linear porosity.

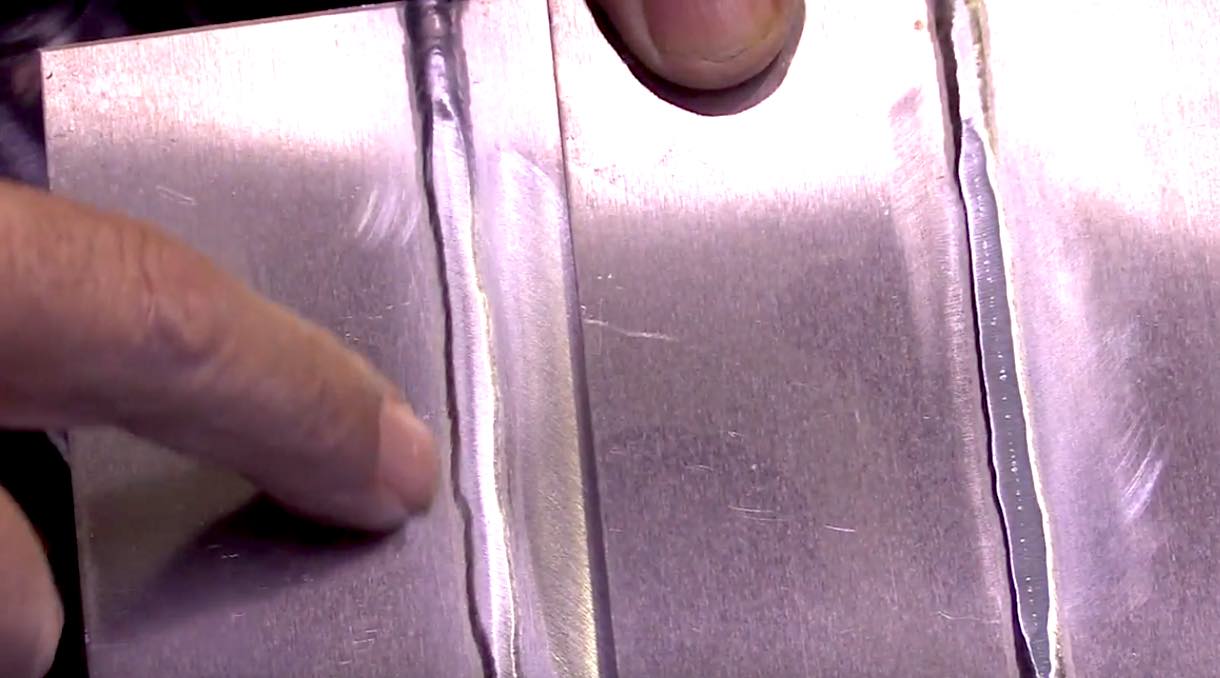

Linear porosity is bad. The limits for linear porosity in code books are much more stringent than scattered porosity.

that is due to the fact that linear porosity is much more likely to form a crack.

So how do you determine if your cleaning method is up to snuff for x ray without an x ray test.

One way I have learned is to blend off the penetration side of the plate using scotch brite discs.

I start with a brown one and then use a red one and I have found that will reveal any significant porosity.

you could even take it a step further and use finer polishing wheels to reveal really small porosity.

This is just a down and dirty information test not sanctioned by the AWS ANSI, or ASTM. Its just a really quick way to get some results to know if your process and procedures on on the right track.

aerospace welding tests

there was a time when I administered a whole bunch of tests like the one shown in the video.

The test plates would be sent to x ray after a visual test.

there was once a time when I send some test welds to x ray and they all failed...all the aluminum tests anyway.

That is where I learned this down and dirty technique for testing an aluminum 1G butt weld test to determine if changes in cleaning procedure were affecting x ray results.

x ray testing is great if you can get immediate results.

But that is often not the case in a facility that primarily is concerned with testing actual aircraft parts and not test welds.

So while not a conclusive test, blending and polishing a weld does provide immediate information.