TIG stainless steel

IF you are searching for tips on how to TIG stainless steel, I hope this page helps you.

There are over 50 videos here on how to tig stainless.

The video below lays out best practices for TIG stainless Steel

Gas Shielding for TIG stainless steel

### Importance of Gas Shielding in TIG Welding Stainless Steel

In TIG (Tungsten Inert Gas) welding, especially when working with stainless steel, gas shielding is critical for several reasons. Here's a simple explanation:

#### 1. **Protection from Contamination**

- **Shielding Gas**: Argon is the most common shielding gas in TIG stainless steel welding. and in fact, the most common shielding gas across the board for tig welding all types of metals.

- **Purpose**: The argon shielding gas creates a protective atmosphere around the weld area, preventing contamination from oxygen, nitrogen, and other atmospheric gases.

- **Result**: This protection helps maintain the integrity of the weld and also helps the weld pool flow better.

#### 2. **Prevention of Oxidation**

- **Oxidation**: When stainless steel is exposed to air at high temperatures, it oxidizes, forming a layer of oxides.

- **Effect**: If this oxidation is excessive, it can compromise the stainless properties.

- **Solution**: Shielding gas prevents oxidation by displacing the air around the weld, resulting in a smooth, shiny, and clean weld.

#### 3. **Improved Weld Quality**

- **Consistent Arc**: Shielding gas helps stabilize the welding arc, ensuring consistent heat application and better control.

- **Weld Strength**: By protecting the weld from impurities, the gas helps maintain the mechanical properties of the stainless steel, resulting in a stronger and more durable weld.

#### 4. **Corrosion Resistance**

- **Chromium Oxide Layer**: Stainless steel’s corrosion resistance is due to a thin layer of chromium oxide.

- **Importance of Clean Welds**: A clean, oxide-free weld allows this protective layer to form correctly, maintaining the corrosion resistance of the material.

### How to Ensure Proper Gas Shielding:

- **Use Pure Argon**: Ensure you use high-purity argon or an appropriate argon-based mixture as your shielding gas.

- **Flow Rate**: Flow rate is usually determined by the cup size used. Set the gas flow rate correctly to cover the weld area adequately without wasting gas. Usually 2-3 times the cup size will be a good flow rate...example: a #10 cup x 2.5 = 25 cfh.

- **Proper Setup**: Make sure the welding torch and gas nozzles are in good condition and correctly positioned to ensure optimal gas coverage.

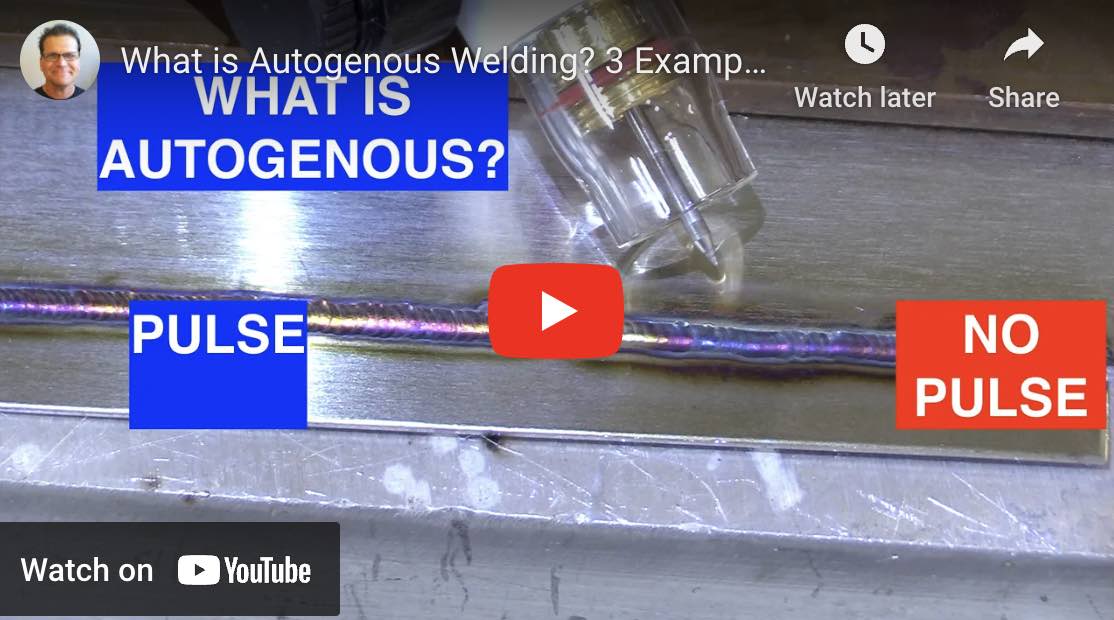

What is autogenous tig welding?

Autogenous is a fancy term for welding without using filler rod.

Sanitary stainless tubing is welded without filler metal.