What is the Best TIG cup for TIG WELDING Aluminum?

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Tig Cup for Aluminum

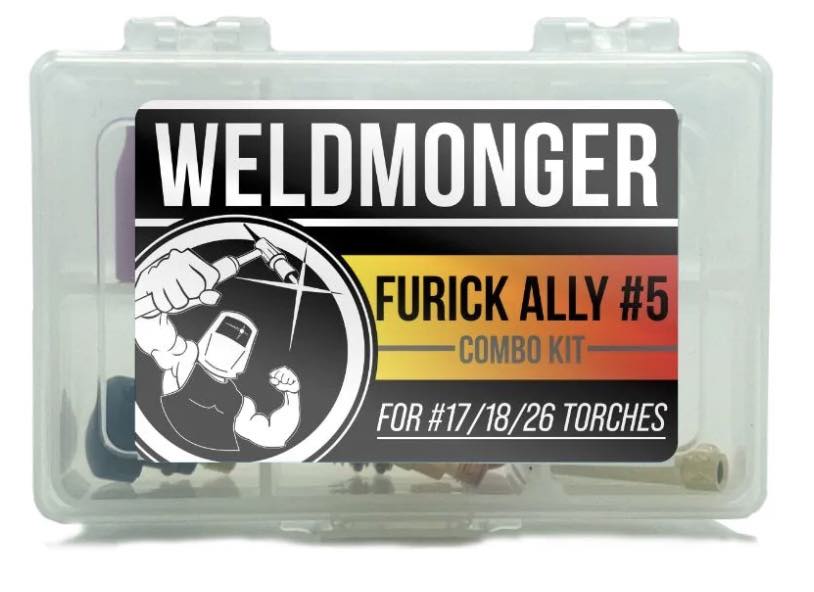

There is a reason so many top welders like a #5 cup for getting full penetration on aluminum. learn more at weldmonger.com

This #5 combo kit includes a clear #5 as well as a ceramic #5 cup along with collet body and all the parts needed to fit your torch. We have a kit for #9-20 style torches as well as 17, 18, 26 style .

Is it a #6 gas lens?

...or a #5 cup with standard collet body?

Does it even matter?

It definitely matters.

But it depends what you are welding.

Video Shows 7 Tips for TIG Welding Aluminum

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

In this video, I want to start the conversation about "What is the best TIG for Aluminum?"

And in future videos, I can address specific situations where certain tig cups seem to work best.

there are lots of options available when it comes to TIG cups.

and certain cups are designed to be used with certain Tig torches.

Lets begin by discussing gas lens style cups

Gas lens cups

Sometimes I like to use a gas lens setup and when I do , I usually try to use the smallest size gas lens cup that provides adequate shielding for the job.

The video shows a fillet weld on a tube that has 1/4" wall thickness so I used a #6 gas lens cup.

A #8 cup would have also been just fine for this application but would have required a bit more gas flow and since I was using a small 200 amp inverter welder along with a 17 air cooled torch, the #6 cup actually helped focus all the arc energy into the puddle instead of using up some for extra cleaning action outside of the bead.

(I know this might sound like total BS to some folks, but cup size and gas flow actually do affect heat input and when you are limited by the amperage of your welder, you learn workarounds)

I also use stubby gas lens setups quite a bit but having more mass in the collet body seems to help with an air cooled torch.

Furick #8 pro clear cup

Another cup I like to use for applications under 200 amps is the Furick #8 pro clear cup (and now there is a #7 that I like even better for aluminum.)

Not only is it a great all around cup for all metals, but its clear so there are times when I look right thru it to weld in corners.

It also helps me see better. I am in my 60s now and this cup really helps light the path and also really helps with me filming.

It works with 9 and 20 style torches simply by slipping an o ring over the gas lens.

For 17, 18, and 26 style torches, an adapter kit is needed.

Stubby Gas Lens kit

I have both water cooled and air cooled TIG torches.

I love having water cooled but I often use an air cooled torch anyway because I make welding videos and the average guy in his garage most often is using an air cooled torch.

When I use a standard 17 style air cooled torch, I almost always use a stubby gas lens.

And when I TIG weld aluminum, I usually choose the #6 cup.

It just seems to be the best all around choice.

In the video, I used a #6 to weld a full penetration butt joint.

Standard #5 cup with collet body

The standard #5 cup is a go to cup for a lot of really good tig welders.

The photo above is a kit designed for use with #9 and #20 torches

One of the main benefits to using a #5 cup is argon savings.

a setting of only 12-15 cfh works in most situations but since flowmeters are not all calibrated accurately, it pays to test out the argon flow setting with a gas flow tester or by actually puddling on scrap aluminum to verify the etch zone.

For me, the #5 cups work good for 1/8" and thinner aluminum.

Another benefit of a standard collet body #5 cup is the narrow profile that can sometimes help you with limited access welds.

Gas Flow Tester by Stronghand Tools

Conclusion

The answer to the question..."what is the best tig cup for aluminum?"

is ...

It really just depends on the type of work.

There are lots of options and there are ways to make one cup work for a lot of different situations...but a #5 definitely is in the conversation.