Pulse TIG settings PrimeWeld TIG325x

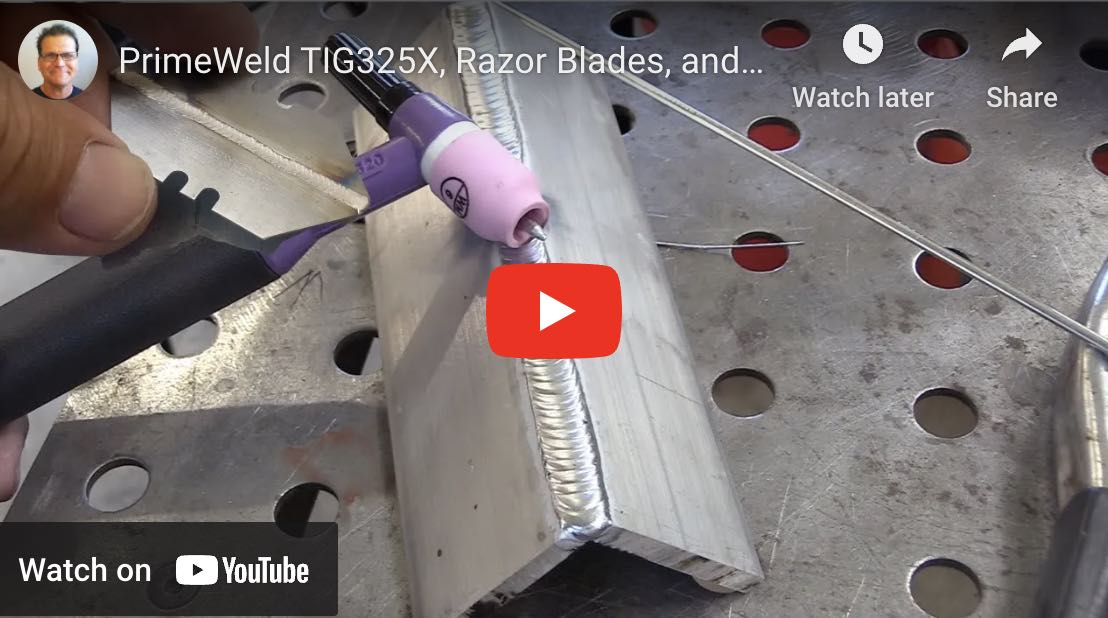

The video below shows 7 tips for TIG welding aluminum

There is no one size fits all pulse setting that works for every application.

The following pulse settings work well on a 16ga stainless outside corner joint if you are trying to limit distortion and discoloration

1 pulse per second

5% background

30% pulse duty

Chill bars can help a lot too when it comes to limiting distortion.

Pulse TIG settings for different thickness and metal types

Primeweld TIG325x Videos

I like the digital readout feature on the primeweld tig 325x. It makes setting pulse rates easier.

water cooled package shown below with ck 20 torch

Learn more about PrimeWeld deals at weldmonger.com

The 3 main settings for pulse tig are

- pulses per second (pps)

- background current ( a percentage of peak pulse)

- pulse duty ( sometimes called peak pulse or pulse width which is the percentage of time the peak pulse is on)

Pulse tig can be helpful but is not always a benefit in manual welding due to the weldor making sub conscious adjustments.

That said there are several applications where pulse settings can help control heat and distortion.