How to Weld Titanium (TIG Tips)

- HOME

- Welding Titanium

- How to Weld Titanium

Watch my Best 3 Videos on How to Weld Titanium here

Table of Contents for How to Weld Titanium

Identify to make sure it's Titanium

Shielding the welded side with a Big cup or trailing shield

Practical example of a Titanium Bike Frame build

The Most Commonly welded Grades of Titanium

These are the basics of how to tig weld titanium...

The 3 C's of tig welding titanium are...

- clean

- clean

- clean

The Weldmonger Furick Arsenal Kit has all the cups you need for titanium, chromoly, aluminum, and other alloys

Clean the metal and filler metal with acetone, use clean gloves and shield any area that will get red hot with argon.

The 3 biggest mistakes to know when learning how to tig weld titanium

It helps to know some things that can go wrong with titanium because these mistakes can scrap a part and parts made from titanium are usually ver expensive.

1. First and worst is...not recognizing that the part you are welding is actually titanium.

Titanium can display a finish or sheen that resembles stainless steel or inconel and if you weld titanium with any other filler rod than a titanium filler rod then guess what? you will start hearing "tink!! tink!! tink!!" and that is the bead letting you know its cracking and that your day just got worse.

When a filler metal like stainless steel or nickel alloy mixes with titanium it creates brittle intermetallic compounds that are brittle like glass.

When this happens, the entire bead will need to be removed along with a little extra base metal.

Removing a 1/4" gap of metal might just scrap a part....or at the very least require a patch and a lot more work.

Think about someone asking you to weld an exhaust component and to you it looks like stainless and maybe you have seen a bunch of stainless exhaust parts that look just like this one.

But actually it is not stainless. It's .032" thick titanium.

Its a one inch long exhaust crack and you weld with it using a stainless filler rod with a bead about 3/16" wide....The entire bead plus a little extra will need to be ground out and now you have a 1/4" wide gap to fill on .032" thick titanium...Not Good!

The same thing can happen just by accident if you leave other filler metals on your work table while tig welding titanium.

So best practice is to clean your work area and remove any filler metal other than your titanium filler metal from your table.

And remember that if you accidentally use a titanium filler rod on a stainless part, you will have a bad day.

The best way to identify titanium is with a spark test using a sanding disc.

Pick an area where a few grinding marks wont compromise the part and use a sanding disc around 120 grit and apply just enough pressure to make sparks. Titanium sparks are almost white and much brighter than any steel sparks.

2. The second biggest mistake is not purging the back side on full penetration welds

Titanium is what is known as a reactive metal.

It reacts with elements like oxygen, nitrogen, and hydrogen in the air when its molten or even red hot and forms brittle compounds and also a brittle oxide layer known as alpha case.

Not purging the back side of a full penetration stainless weld is bad enough but a stainless unpurged weld might actually last a while for some applications .

.. But not purging the back side of a full penetration titanium weld is horrible and the weld wont hold up very long for any application where the weld is stressed even a little bit.

3. 3rd Worst thing is not using a big enough cup or trailing shield

Using a standard small cup for tig welding titanium just wont do.

You risk contamination of the molten puddle and at the very least, excess discoloration which for most welding codes is cause for rejection.

In a fixture with chill blocks a jazzy 10 cup can work but on jobs where chill bars are not possible, something like a furick BBW is the ticket to provide a large blanket of argon shielding and a silver weld.

4. The 4th worst thing is not cleaning the metal.

The first 2 mistakes are much worse than this one.

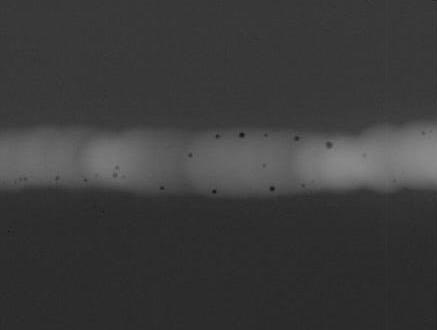

But not cleaning titanium before welding usually will result in porosity.

so if the weld will be subject to x ray testing, not cleaning it will almost always fail an x ray test.

x ray negative of an .040" titanium butt joint with porosity due to not cleaning

Mike Zanconato Shows us how to tig weld titanium bike frames

The most common grades of titanium

The most common grades of titanium that are TIG welded are:

1. Grade 2 (Commercially Pure Titanium)

- Description: Unalloyed, medium strength titanium.

- Most commonly TIG welded titanium grade.

- Uses: Aerospace, chemical processing, medical equipment, marine components.

- Welding Notes: Excellent weldability. Requires very clean conditions and proper shielding (argon gas coverage).

2. Grade 5 (Ti-6Al-4V)

- Description: Titanium alloy with 6% aluminum and 4% vanadium.

- The most widely used titanium alloy overall.

- Uses: Aerospace, medical implants, high-performance automotive parts.

- Welding Notes: More challenging than Grade 2 due to higher strength and potential for microstructural issues. Welded often in inert gas chambers or with trailing shields.

3. Grade 9 (Ti-3Al-2.5V)

- Description: Titanium alloy with 3% aluminum and 2.5% vanadium.

- Known as “half-6-4” (half the alloying content of Grade 5).

- Uses: Aerospace tubing, bicycle frames, sporting goods.

- Welding Notes: Easier to TIG weld than Grade 5. Good balance of strength, formability, and weldability.

4. Grade 1 (Commercially Pure Titanium - Extra Soft)

- Description: Softest and most ductile of all grades.

- Uses: Chemical processing, marine, medical applications.

- Welding Notes: Welds very easily. Great for forming and corrosion resistance.

5. Grade 3 (Commercially Pure Titanium - Higher Strength)

- Description: Stronger than Grades 1 and 2 but less ductile.

- Uses: Industrial applications where slightly more strength is needed.

- Welding Notes: Welds well, but may require more attention to shielding due to higher reactivity.

TIG Welding Considerations for Titanium (All Grades)

- Argon shielding is critical — use 100% argon with proper flow rate.

- Back purging and trailing shields often required to prevent oxidation.

- Contamination is your enemy — titanium absorbs oxygen, nitrogen, and hydrogen easily when hot, leading to brittle welds.

- Use a dedicated brush and clean gloves to handle titanium before welding.

- Color is a clue — clean silver welds = good. Blue, purple, or gray = less than optimal shielding.