How to Vertical Stick Weld

- HOME

- STICK WELDING

- How to Vertical Stick Weld

Did you search for "how to vertical stick weld?

Well, you found the right place because I have more short videos on this topic than any other website.

Are you wanting to know how to vertical stick weld uphill or downhill?

I need to give you a heads up that not all electrodes will weld downhill.

There are a few exceptions but for the most part, 6010 and 6011 rods can weld both uphill and downhill.

But 7018 electrodes should not be used for welding vertical downhill.

Stick Welding uphill in a vertical position can be a bit more challenging than welding in flat or horizontal positions because of gravity and the fact that its harder to get steady and comfortable, but with practice and the right technique, you can achieve good results. Here's a step-by-step guide on how to vertical stick weld for beginners:

- Safety first: Before you start welding, make sure you have the necessary safety equipment. Sparks and fire balls are more likely to land on your arms when doing vertical stick welding so a long-sleeved welding jacket or flame-resistant welding sleeves can prevent burns. You also need to wear welding gloves, and boots and make sure you are working in a well-ventilated area or use proper ventilation equipment.

- Prepare your metal: Its ok to practice on hot rolled steel without cleaning but you will get better results with clean metal.

- Set up your welding machine: Adjust the welding machine settings according to the thickness of the metal you are welding and rod you are using. Different manufactures of stick rods go to a lot of effort to list amperage and polarity for each electrode so it can save you time and effort to refer to the manufacturer's recommendations for the specific electrode and amperage settings. Ensure the machine is grounded properly.

- Choose the right electrode: Select the appropriate electrode for your project. Different electrodes have specific characteristics and are designed for different types of metals and welding positions. For vertical welding, choose an electrode with good vertical welding capabilities and penetration.

- Position yourself: Stand in a comfortable and stable position where you can have good visibility of the weld joint. Ensure you have a secure footing and maintain a balanced posture throughout the process.

- Strike an arc: Hold the electrode holder firmly in your dominant hand and rest your other hand on a stable surface to provide support. Position the electrode at a slight angle (around 10-15 degrees) against the metal surface. Tap the electrode against the metal to create an arc, then quickly lift it back to establish a stable arc length.

- Control the arc length: Maintaining the correct arc length is crucial for a successful weld. The arc length should be approximately the same as the diameter of the electrode. Practice keeping a consistent distance by adjusting your hand speed and movement.

- You might need a slight weaving motion: When welding vertically, you sometimes need to use a slight weaving motion to allow the bead to flatten out. For a vertical uphill single pass fillet weld, or the first pass in a multiple pass weld, a slight upside down V motion really works well

- Control travel speed: The speed at which you move the electrode along the joint is important. If you move too slowly, the weld may pile up too much and give you a convex or ropey weld. If you move too quickly, or dont hold a tight enough arc length, you might get undercut on the edges of the weld (the toes)

Vertical uphill stick welding requires practice to develop good technique and control. The best way to get practice is padding beads uphill with the stick rod you need to learn.

How to vertical stick weld downhill

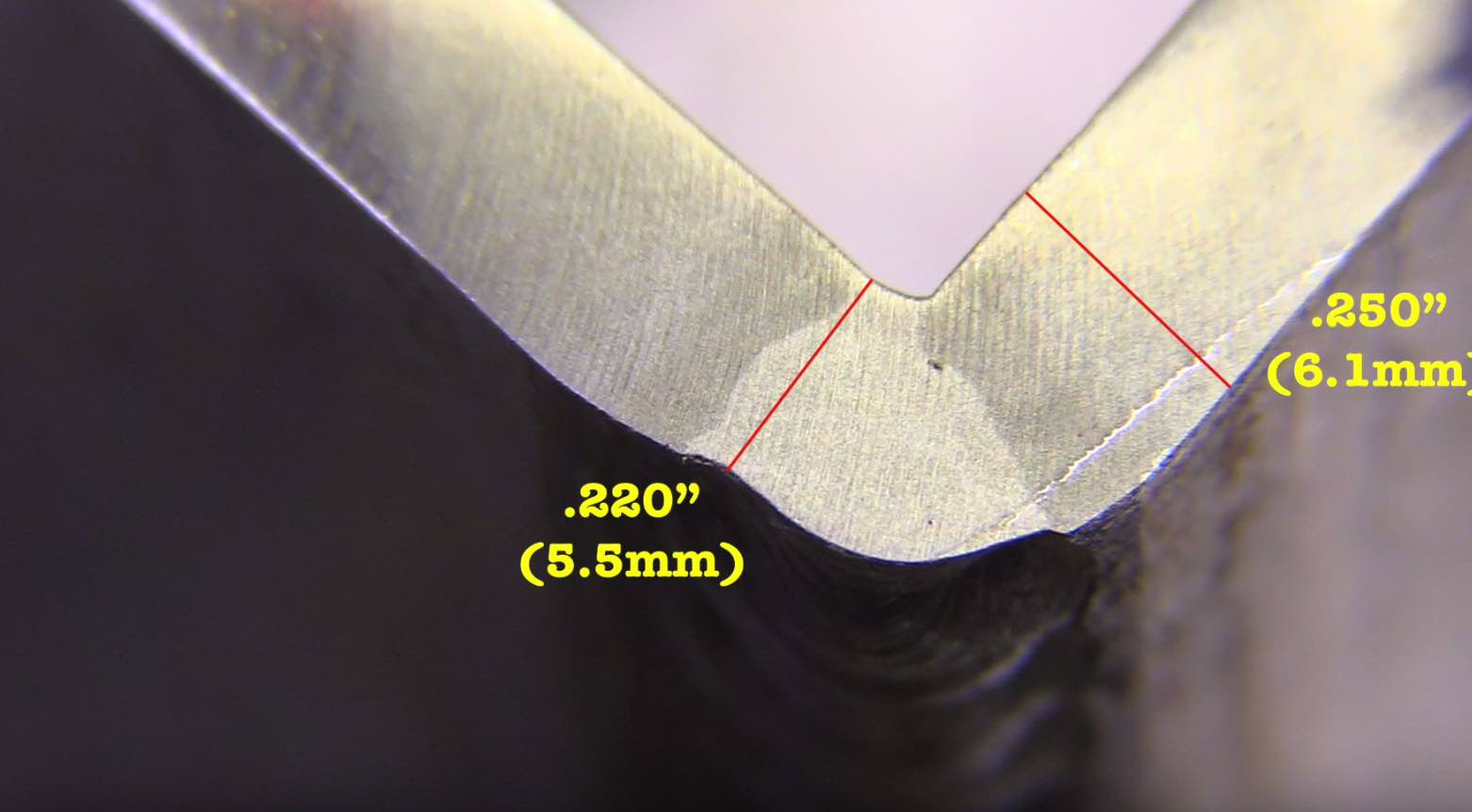

For structural welds, stick welding downhill is generally not recommended. However, for open root pipe root joints using 6010 or other XX10 electrode like 7010, its industry standard in the oil and gas industry. You really need to follow the guidelines provided by the welding procedure specification (WPS).

The welding procedure will specify uphill or downhill.

I have a whole series of videos on stick welding both downhill and uphill using 6010 here....