How to TIG Weld Cold Rolled Steel - Corner and Lap Joints

This page is about how to tig weld cold rolled steel corner joints and lap joints.

Cold rolled steel has a cleaner finish than hot rolled steel and does not have a thick layer of mill scale like hot rolled steel.

Cold rolled is usually clean enough that it can be tig welded without cleaning or prep work.

But it will weld even better if you take the time to clean it.

A flap disc followed by a wipe down with acetone usually works just fine.

I like to use a gas lens for tig welding cold rolled steel as well as most other metals...and I used a jazzy 10 clear cup (helps with filming) and a furick 12 ceramic cup for the lap joints.

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

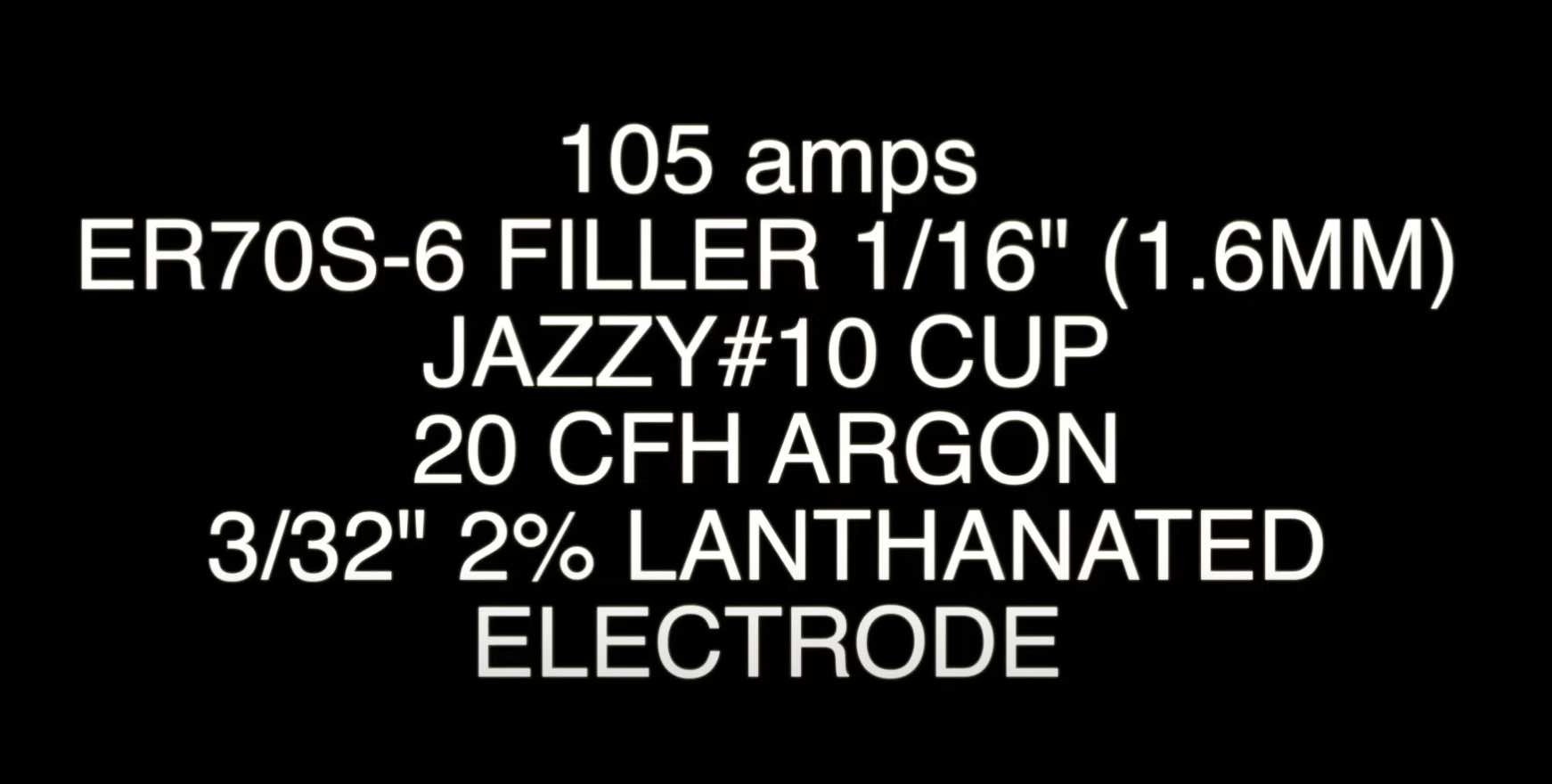

corner joint settings for 11ga cold rolled steel

lap joint settings for 11ga cold rolled

I hope you enjoyed this page about how to tig weld cold rolled steel corner joints and lap joints.

If you are interested in any of the gear used in the video you can learn more at weldmonger.com. That is my online store and that is how I support these videos.

Some thoughts on tig welding cold rolled steel

Every now and then, when I am tig welding cold rolled steel, I get an irregularity that is hard to understand.

It usually happens when I have a slight pause in my travel speed.

After a lot of thought, I think I finally understand what happens.

Cold rolled steel is a bit stronger than hot rolled steel due to the cold working process. Than means the grains in cold rolled steel are elongated from the rolling process.

When cold worked steel gets hot enough, elongated grains recrystallize into blocky grains.

I believe that is when you will see a puddle quiver or wander a bit.

I have been tig welding a simple bead on cold rolled plate and things are going along just about perfectly when all of a sudden, the puddle acts weird and I get a very irregular ripple in the bead pattern.

I first thought it was just me. Because believe me...I am perfectly capable of screwing up a bead even after 45 plus years of welding.

But because I get to review the film like a monday morning quarterback, I replay things in slow motion sometimes.

That is why I have come to the conclusion that tig welding cold rolled steel is more difficult to make look good than 4130 chromoly or even hot rolled steel.