What is Blue Tungsten used for?

scroll down for Videos

- HOME

- TIG WELDING

- Blue Tungsten Used for

If you just search for "what is blue tungsten used for?" then you found the best page on the web.

The video below shows switching back and forth from steel to aluminum using blue tungsten for both

The answer to the question "what is blue tungsten used for?" is....

Everything!

2% lanthanated is blue tungsten and is one of the very best all purpose tungsten electrodes I have used.

I use it for every metal...

Carbon and low alloy steels like 1010-1020 steels, 4130 chromoly, stainless steels, nickel alloys, aluminum, magnesium, titanium, cobalt, tool steels, copper alloys...,..Everything....even pot metal.

Other good alternatives are E3 ( purple) and CK LaYZr ( chartreuse)

But 2% lanthanated tends to hold up better at high amperage.

More Tungsten Tips

- There is no one single color tungsten that is the best for everything.

- some tungsten types excel at low amp starts and restarts.

- E3 and LaYZr are 2 examples

- Some tungsten holds a sharp tip longer on DCEN.

- 2% thoriated and 2% ceriated are 2 examples

- Some tungsten holes a rounded tip longer at mid amperage ranges on aluminum.

- E3 and LaYZr ( these work almost identical to me)

Best practices on cutting and sharpening tungsten electrodes

- Some tungsten splits very easily so it is best to cut using a grinder or diamond wheel.

- Some authorities are adamant that you shouldn't even snap tungsten even when scored with a grinder but I have never had a single issue doing this.

- Just make sure to score it at least 2/3" thru before breaking.

- A dedicated tungsten grinder with diamond wheel is nice to have but not completely necessary ...especially for beginners.

- Just make sure all your grinding marks run lengthwise

What size tungsten should I use? Does it matter?

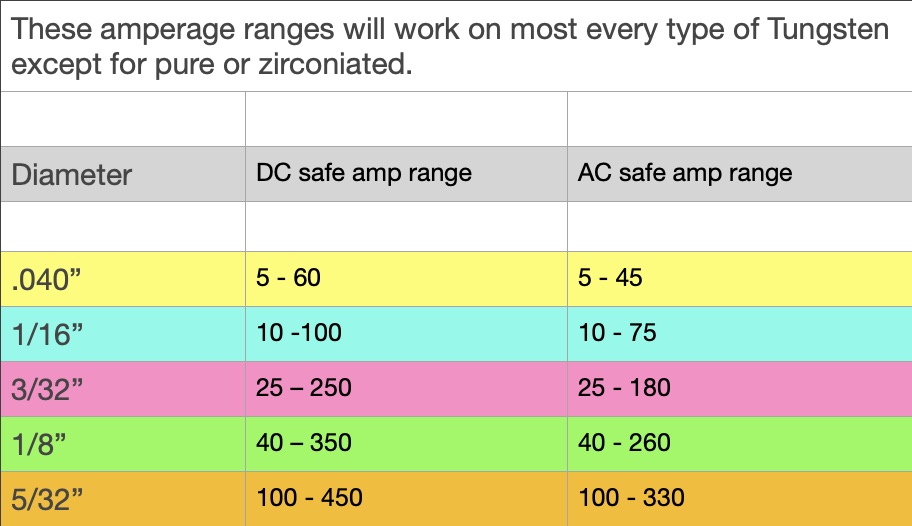

A 3/32" diameter 2% lanthanated tungsten will usually handle anything a 200 amp tig inverter can do.

When you start to approach 200 amps on aluminum, stepping up to a 1/8" tungsten makes sense.

In fact, some folks like to keep a 1/8" tungsten in the torch for almost everything....even really thin metals.

Nothing wrong with that but you will usually need to sharpen the tip differently for thinner metals.

It is possible to weld razor blades and coke cans using a 1/8" tungsten with a properly tapered tip.

There are a few drawbacks to using a 1/8" tungsten for everything:

1/8" tungsten costs more

takes longer to sharpen and wears out a diamond wheel faster than smaller diameter tungsten.

might require a larger cup if you like using a #4 or #5 for certain jobs

One last thought:

I have a 200 amp AC/DC TIG welder that has been shown in over 30 videos and all I have ever used with it is 3/32" 2% lanthanated tungsten. (blue tungsten)