Aluminum TIG Welding Technique - Brad Goodman

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Aluminum Tig Welding Technique

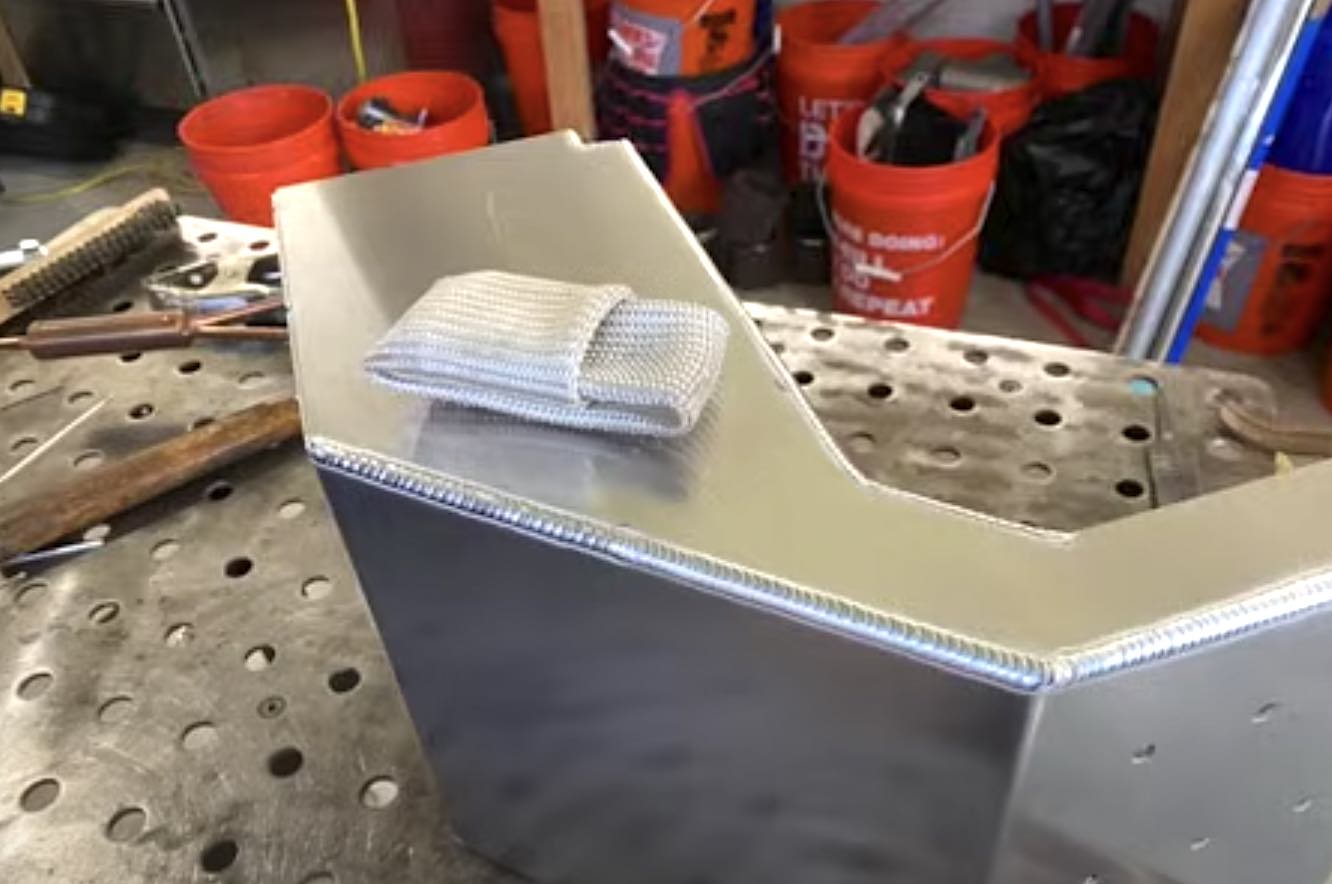

TIG welding 5052 aluminum for a Dog Feeder Project.

Before we dive into welding techniques, If you watched the video already, you saw Brad using a TIG Finger® to glide along those corner joints.

Why not add a TIG Finger® bundle to your cart right now? just click here

If you have welded much aluminum, you know just how uncomfortable it can be propping with bare gloves.

But slide a TIG Finger® on and you can focus on making the weld instead of the blisters you are getting on your knuckles.

Why not add a TIG Finger® bundle to your cart right now? just click here

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

Pumping the foot Pedal technique for tig welding aluminum

Pulsing with the pedal is not necessarily a better TIG welding technique ….it’s just another tool on the toolbelt to achieve a certain result.

Brad owns Goodman Metal Products in Wesson Mississippi.

Brad makes aluminum dog boxes, dog feeders, and also does quite a bit of work for motorsports customers.

Either way, Brads customers want that "stack of dimes" look.

This video of Brad putting together one of his dog feeders shows how Brad gets a fairly large bead along with full penetration on outside corner joints by pulsing with the pedal.

The material is 5052 aluminum .090” thick.

Brad set the amperage to around 180 amps because whenever you are pulsing…whether with the pedal or using pulse settings on the machine, you need more amperage for the peak portion than you do when welding with a constant even amperage.

You might notice in the video that Brad is not backing off the foot pedal a whole lot on the low amp side.

I would estimate, that if pulse settings were used, a background current of 60-70% would closely resemble what Brad does with the foot pedal amperage control.

The benefit of pulsing manually instead of with pulse settings is the adjustments you can make on the fly.

When Brad welds around corners, he pulses current only when he is ready for it and that gives him more control for the parts he makes like this dog feeder.

What is the best filler metal for 5052 aluminum?

For most applications 5356 is the best choice in filler metal for tig welding 5052 aluminum.

4043 is discouraged due to crack sensitive mixtures of silicon and magnesium.

A great filler metal chart for tig welding aluminum is right here