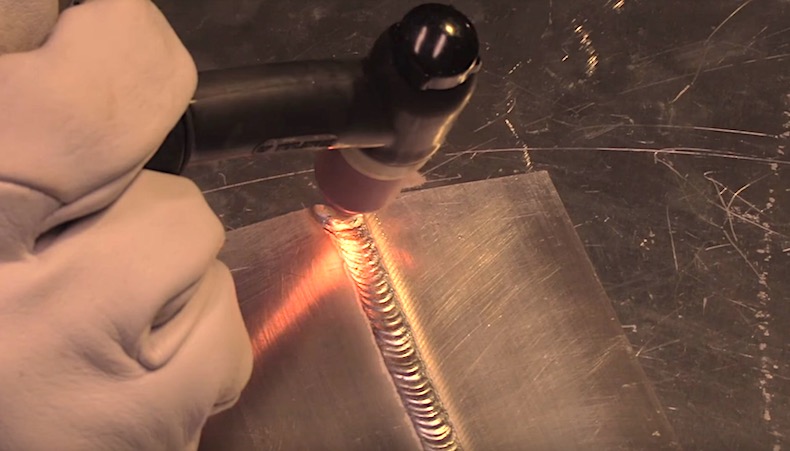

TIG Welding an Aluminum Butt and TEE joint

This video demonstrates TIG welding Aluminum Butt and Tee joints.

There are different objectives for each.

Full penetration is usually needed on Butt joints....while a Tee joint is usually a partial penetration joint.

basic settings are 100-140 amps using foot pedal.

at times, i used nearly 140 amps but when the aluminum gets soaked with heat, I used the foot pedal to use less amperage.

AC balance set to 30% cleaning, AC frequency set to 100 hz using advanced square wave.

pre flow set to 1.5 sec and postflow set to 8 sec. 3/32" 2% lanthanated electrode, and 3/32" 4943 filler metal.

I have learned that 1.5 seconds on preflow provide for much cleaner arc starts.

4943 welds a lot like 4043 but has better overall properties than 4043.

for the butt joint, I used a #6 cup with 15cfh of argon, and for the Tee joint, I used a #8 furick pro clear cup to aid with filming the arc.

Aluminum Tee joint

I increased the flow rate to 18 cfh for the #8 cup but all other settings were same as the butt joint.

For the Tee joint, I usually extend the electrode further than I do for a butt joint.

that is because in order get adequate penetration into the root of the joint, it requires a tight arc length is needed to push the puddle into the root.

I also lengthen the arc while I add filler metal in order to prevent tungsten contamination.

The #8 furick cup allows me to see it all happen.

One of the best ways to get better at tig welding aluminum is to weld the "aluminum drill".

Thats what I call padding beads on plate.

The slowest thing to develop is usually your filler wire feeding hand.

And welding a pad of beads on aluminum plate requires your filler wire hand to improve and get more proficient.

Try to keep the hot tip of the rod shielded in the argon envelope while not flicking the electrode.

Its not easy at first, but as you weld a whole bunch of beads, you will get more accurate and comfortable with your wire feeding hand.

And try different ripple spacing, try different size filler wires, try all kinds of things and find what works for you.

This is also a good time to see the difference in tungsten electrodes.

I like 2% lanthanated for almost everything.

But there are other electrodes that work well on AC.