TIG Welding Settings for one inch thick round stock Aluminum on turntable

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Tig Welding Settings Aluminum

- HOME

- WELDER SETTINGS

- Tig Welder Settings

- Tig Welding Settings Aluminum

Our Large diameter Gas lens kit comes with 5/32" setup along with 1/8" and 3/32" and CK worldwide parts

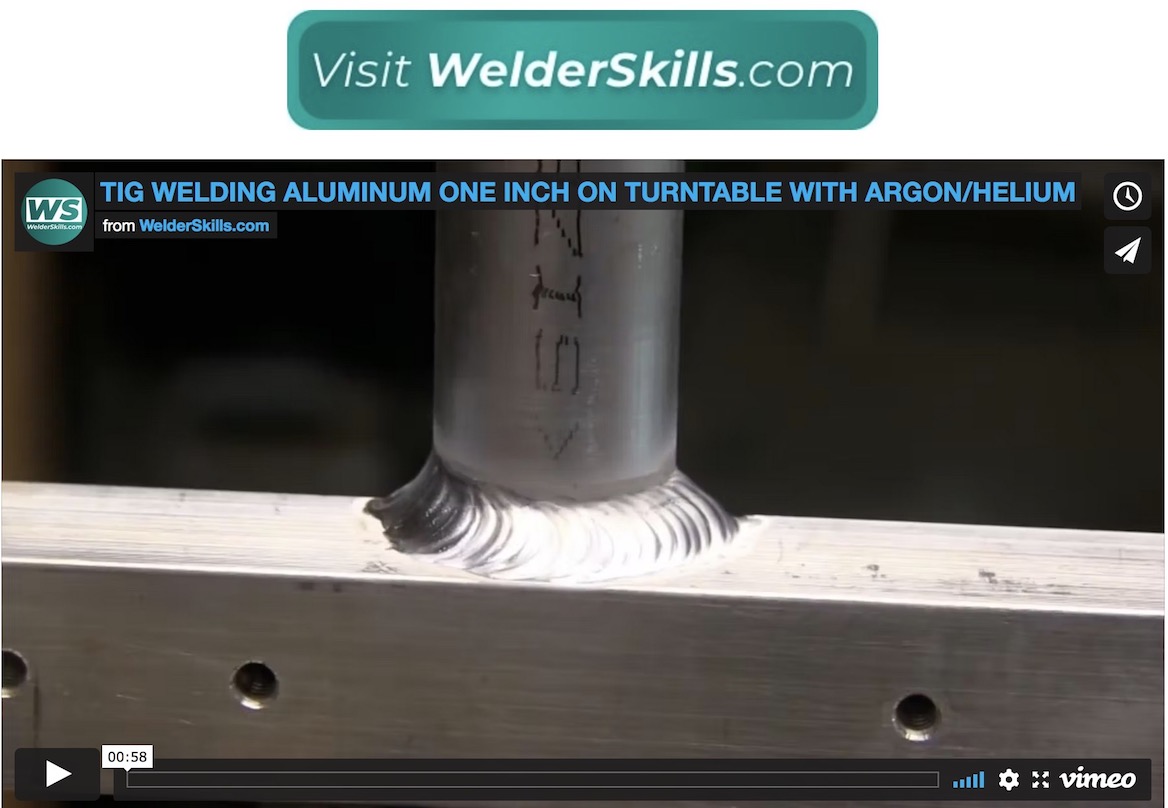

WELD PROCESS = TIG, GTAW, GAS TUNGSTEN ARC WELDING

METAL TYPE = ALUMINUM 6061

THICKNESS = ONE INCH ROUND TO MACHINED FITTING

WELD TYPE = FILLET WELD

JOINT TYPE = MACHINED FIT

POSITION = TURNTABLE WELD

AMPERAGE = 175 AMPS CONTROLLED WITH FOOT PEDAL

TUNGSTEN = 2% LANTHANATED, 3/32"WITH ROUNDED TIP

FILLER WIRE = 3/32” 4043

POLARITY = AC

GAS FLOW = 15 CFH ARGON/HELIUM 50/50 MIX

CUP SIZE = 6

ADDITIONAL SETTINGS = PREHEAT OF 150-200F HELPS

PRE FLOW = MANUAL

POST FLOW = 10 SEC

TIPS: KEEP A FAIRLY TIGHT ARC AND KEEP TORCH ANGLE TO A MINIMUM

Aim for an arc length that is equal or less than the diameter of your tungsten electrode. Torch angle can be forgiving provided your arc length is tight.