115v Mig Settings - wire feed speed and voltage

If you like this video on 115v mig settings, have a look around....there are many more videos here on all types of welding.

learn more about the MIG 180 at weldmonger.com

Balancing the voltage and wire feed speed is somewhat like getting an air fuel mixture just right on a carburetor.

You cant just dump fuel in without mixing in enough air to help it burn efficiently.

The engine will run with an unbalanced mixture, You will still get from point a to point b....but the tailpipe might smoke and the car wont be as fun to drive

Or...if you have never adjusted a carburetor, think about the Bass and treble knobs on a stereo sound system. you have to balance them out to get the sound you like.

It is true that wire speed controls amperage but if you don't have enough voltage to burn the wire efficiently, then you wind up with either a lot of spatter, a ropey weld, or some other issue.

Fortunately, wire speed does not have to be exact...there is a fairly wide range of wire speeds that will work.

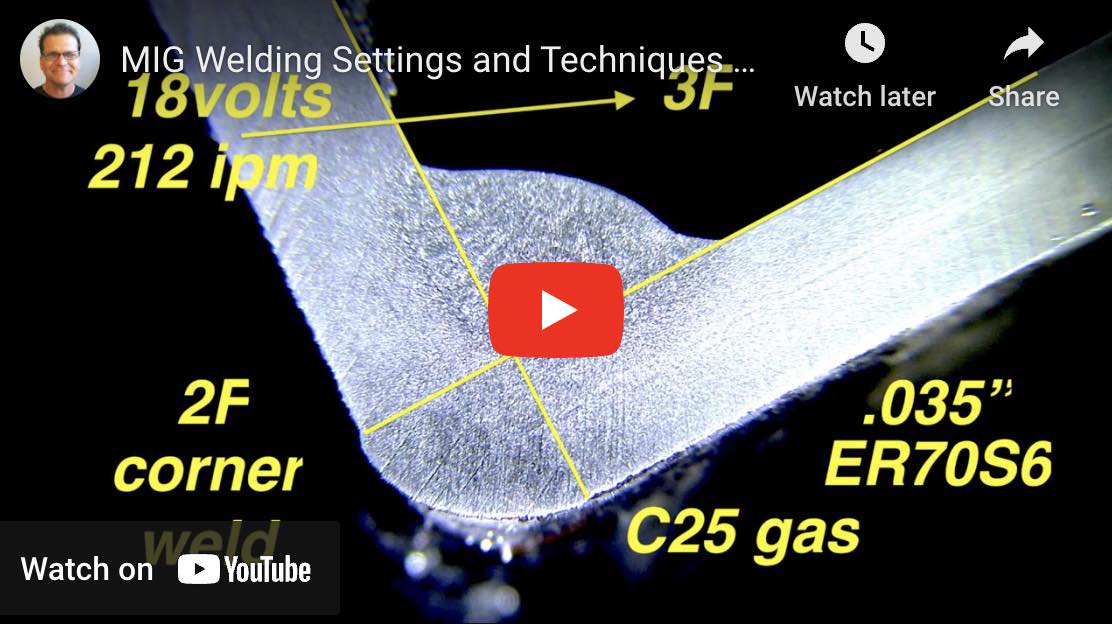

I have a whole page if different mig welder settings for the most common joints and welds right here and each page has a 30 second video with settings and quick arc shots. This is especially helpful for folks who dont weld everyday.

Question from reader on 115v mig settings...

hi,

I have a miller 115 volt welder and there are voltage settings on the welder, what does that indicate and what settings should it be on? thanks

mig settings answer

Here is my down and dirty explanation for 115v mig settings.

If you are using .023-.025" bare wire with argon/co2 gas mix, your wire feed range is 100-400 inches per minute.

100 being for the thinnest steel you can weld,

400 ipm would be used for the absolute thickest steel the machine would handle.

Voltage is another story. I suggest you try setting the wire feed speed first. then get a piece of scrap metal the same thickness you want to weld and adjust the voltage until you get a nice bacon frying sound.

Too little voltage and it will snub and sound like a drive by shooting.

Too much voltage and the wire will try to burn back into a ball or the sound will be a rattle or hiss.

You will see....its very hard to describe but just try it.

so if you wanted to weld 20 ga. or about .030" thick. you would set the wire feed speed to 100. if it does not read in inches, just pull the trigger and count to 6 seconds, measure in inches and add a Zero.

10 inches would equal 100 inches per minute.

Cant find what your looking for? Try Custom Search.

115v mig settings not what you were looking for? see more mig welding tips

What should my MIG gas be set at?

What should my MIG gas be set at?

MIG gas flow rates for short circuit mig welding should usually be set to 25-30cfh but it depends on the nozzle size. Smaller nozzles require less flow rate than larger nozzles

what settings should I use for mig welding?

what settings should I use for mig welding?

For short circuit mig welding, voltage will usually be in the 14-24 range.

14 volts might be used for really thin metal and 24 volts for 3/8" thickness. and wire speed can be as low as 50 and as high as 750 depending on wire diameter.

MIG settings charts can be helpful but are designed for flat fillet welds and are not all that helpful for vertical uphill welding...that is why I have made a special page for mig welder settings right here that also shows vertical uphill and overhead welder settings.