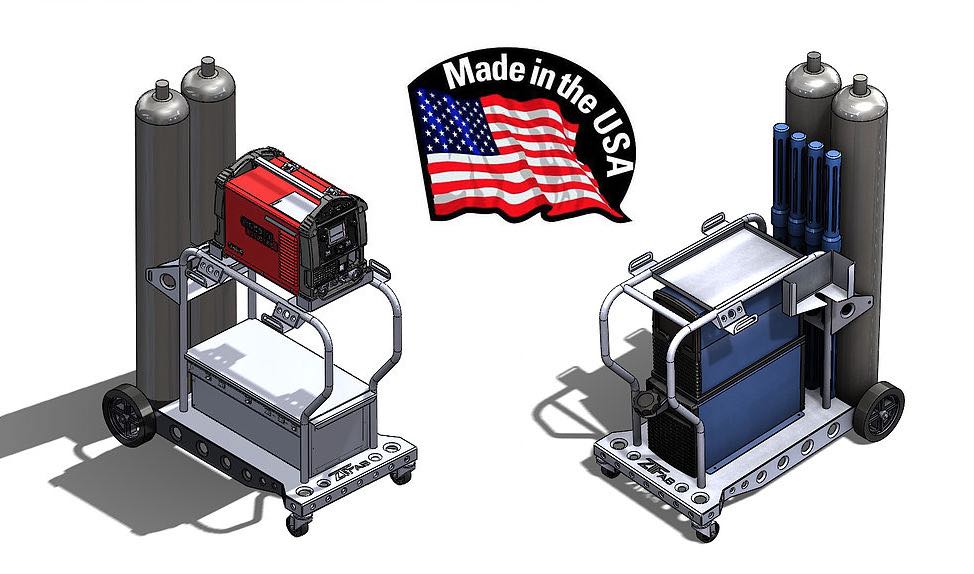

Ztfab welding carts

"ready-to-weld" carts designed by a real welder.

My friend Paul Brinegar of Zero Tolerance Fabrication is better known on welding forums as ztfab.

Paul

does a lot of welding and fabrication for the motorsports industry as

well as other customers and now he has designed his own line of welding

carts.

Ztfab welding carts are cnc plasma cut and dimple die punched and come with heavy duty casters, cast iron solid rubber wheels with grease fittings, and are designed to hold 2 cylinders.

For the most part, every welding cart I have every bought was lacking.

Either too small, too flimsy, or just not designed well.

I built 2 of my own welding carts recently and they work much better than anything I ever bought...but they were time consuming to build.

Now Paul (Ztfab) has created his own line of "ready to weld" carts that are easy to assemble and weld.

you can learn more at all-a-cart.com

or just click the image below

Tig Brazing with silicon bronze

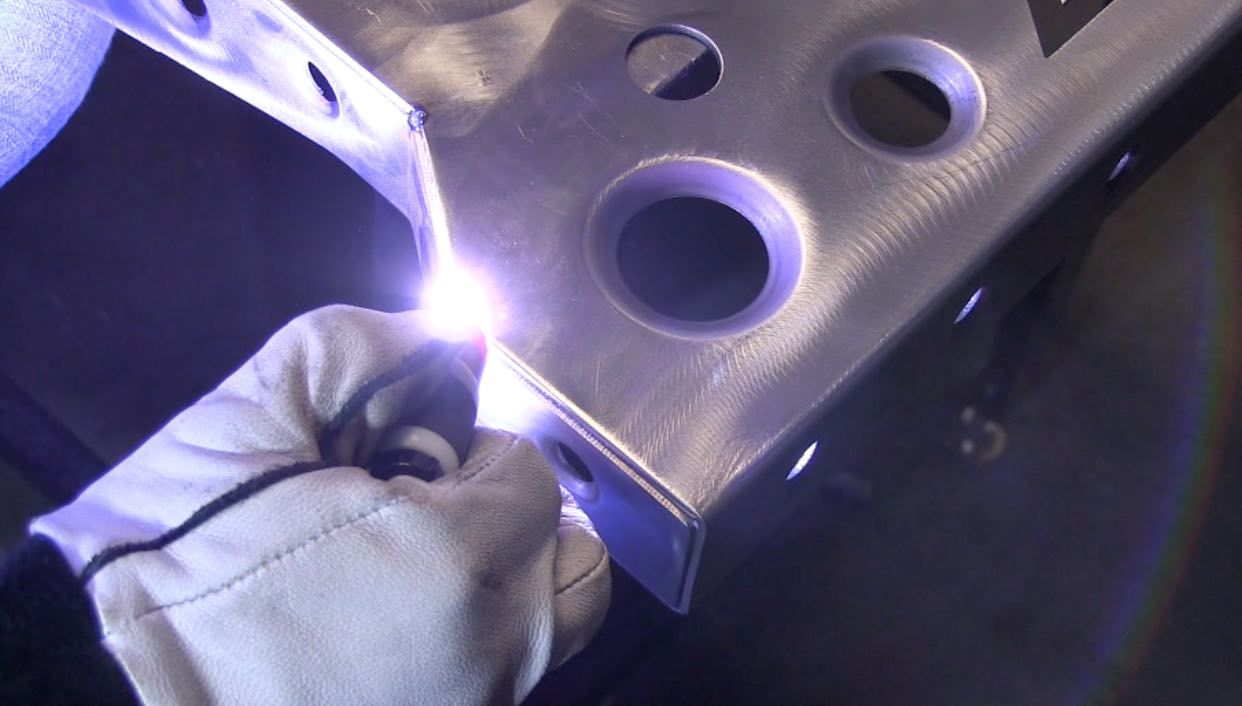

Normally, I would not use silicon bronze for a project like this but these carts are designed so well, that silicon bronze will be plenty strong enough and I wanted to get some practice and also wanted to try some pulse settings.

For tacking up the pieces, I used 160 amps and a quick stomp on the foot pedal.

This is my preferred method of tack welding on projects like this...

I usually set the amperage to 1.5 to 2 times what I would weld with but I only use a short burst of amperage either with a torch switch or by just stomping the pedal and letting of quickly.

Welding vs Brazing vs Soldering

Technically, silicon bronze is a brazing rod when used on carbon steel or other metals that have a much higher melt point.

Welding actually melts the base metal

Brazing does not melt the base metal and is over 840 deg F

Soldering does not melt base metal either and is under 840 deg F

Silicon bronze filler rod has a tensile strength of around 50-60 ksi which is much lower than mild steel filler rod which is usually 70ksi minimum.

But again, the strength of this cart lies in the design.

Wall thickness on this cart is around .100" on the sheet. I used a large fillet size with the silicon bronze filler rod to make sure I got enough strength.

Short burst fusion tacks are a quick way to tack weld using only one hand while holding the fit with the other hand.

Experimenting using 2 pulses per second and lay wire technique worked out pretty well.

The Lincoln TIG 200 square wave has pulse feature with the back ground current and pulse time being fixed at around 50% each.

ZTfab welding carts fit almost every tig inverter out there

There are ZTfab welding carts designed for most of the popular welding machines like the Lincoln TIG 200 square wave, and the Lincoln power mig 210mp, Miller dynasty and maxstar and more.