WorldSkills Welding 2022 - Special Edition at Lincoln Electric, Cleveland Ohio

I just returned from an event called World Skills Welding 2022 Special Edition held at Lincoln Electric’s new welding training facility in Cleveland Ohio.

It was amazing and inspiring… and also very humbling.

It was amazing to see the quality of welds being done by such young welders.

But also humbling to learn just how much work goes into the competition from not only the competitors, but also the volunteer experts and educators that helped train the competitors along the way.

I am here to tell you there are still sharp and hard working industrious young men and women out there who aren’t afraid to sweat and get dirty in pursuit of goals.

I was privileged to film a bunch of them all under one roof competing in a welding competition.

From test welds on plate and pipe, to a pressure vessel tested to 1000psi, to aluminum and stainless tig projects, these competitors were tested for skill, endurance and time management skills with a 20 hour time limit over a 3 day period.

Worldskills welding competition is truly the olympics of welding.

And much like the olympics, you don’t just roll out of bed and sign up.

Competitors qualify for WorldSkills Welding Competition thru a long process.

It starts with skills competitions on a local level.

Simple competitions might be something as simple as a 2f 7018 tee joint fillet weld.

If a student shows a certain level of skill and commitment, they can progress to more difficult and more complex competitions.

In the USA, we have skillsUSA where welders start at the local level, then progress to state, regional, and national events.

The winner of the nationals earns the honor to compete on the world stage at world skills.

Think about this for a minute…

How many high school or college age folks do you know who would make the choice to decline football games, parties, and video games to dedicate time to welding training in order to represent their country on a world stage?

World Skills Welding competitors are truly the top .01%

And I am not strictly speaking of welding skill.

Other important character traits like work ethic, problem solving, and even confidence are gained during the journey of competing.

We need more of this type of thing.

And thats why I went, filmed the video, and wrote this article.

Learn more about SkillsUSA and WorldSkills Welding

Here are some resources to help you learn more about skillsusa and world skills.

Day 1 ... phase #1 of the competition is common test welds.

I would use the term “common test welds” but since the test welds are selected somewhat randomly, occasionally something unusual gets picked like an overhead 7018 open root using Alternating current….thats a really tough one that has been part of the completion in the past.

The selected test joints utilized TIG, MIG, Stick, and Dual shield flux core process in a variety of joints and positions (1G, 2G, 3F, and 6g)

And here is something I found very interesting …

Competitors were allowed to use the welding Machine to its fullest capability …for example, they could use short circuit mig, or pulse spray mig….pulse tig or straight current…etc.

So knowing all the features and settings of a welding machine was a big advantage.

The test joints selected for 2022 world skills welding were as follows:

12 mm 2f tee joint fillet weld using dual shield flux core (total of 3 passes)

12mm 3f tee joint fillet weld using gmaw 2 passes

(Both of these tee joints were tested visually as well as with a fillet weld break test)

10mm 2g open root plate gmaw (mig) all the way

16 mm 1g dual shield flux core with gmaw open root

(Both these test plates were scored with visual inspection as well as X ray test)

6g pipe 4 inch schedule 40 tig root and stick cap

This joint was inspected for acceptable root penetration …visual inspection inside and out and then sent for x ray test (RT) at Lincoln electrics new ATF area. ( an ATF is an AWS Accredited Test Facility)

There were time limits set for all the the phases of the competition so time and work flow management is just as important as welding skill because if a competitor does not finish each phase in the allotted time, big points are lost.

Day one was buzzing and I was not permitted to be in the welding area but I still managed to film a few clips.

Day 2 Phase 2 the Pressure Vessel.

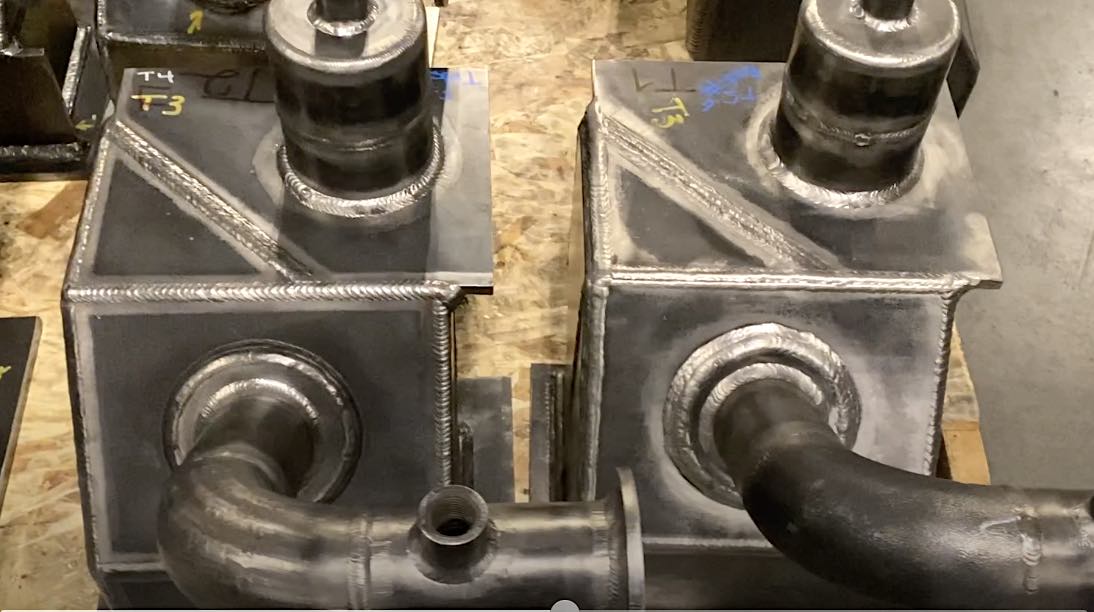

Detailed drawings were available to each welder competing that depict dimensions, weld symbols, and which processes are to be used and where.

All the main welding processes ( tig, mig, flux core, stick) and the vessel has to be welded in position resting on the workbench.

Points can be lost for bead width variation, arc strikes, grinding marks, undercut, porosity, and other defects or indications.

Once the vessel is visually inspected and scored by a team of international experts the vessel is hydro pressure tested to 1000psi.

The smallest leak can cause loss of points and make it difficult to overcome in the overall competition.

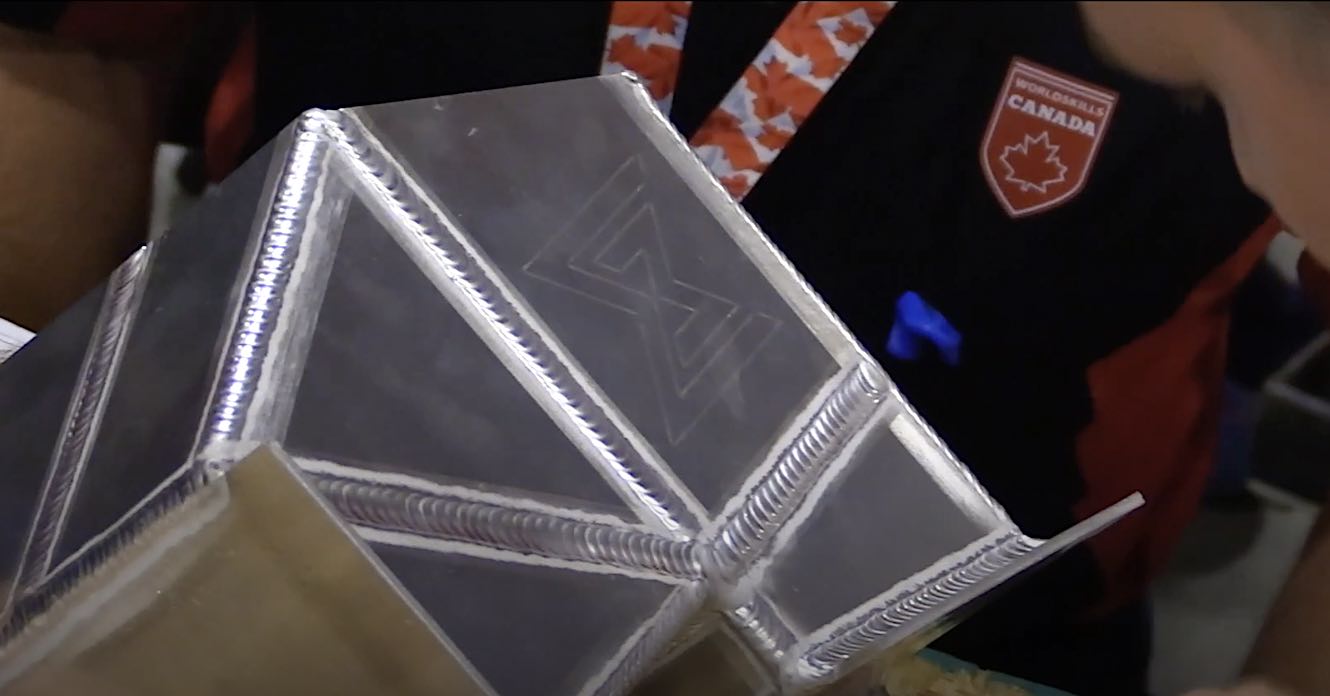

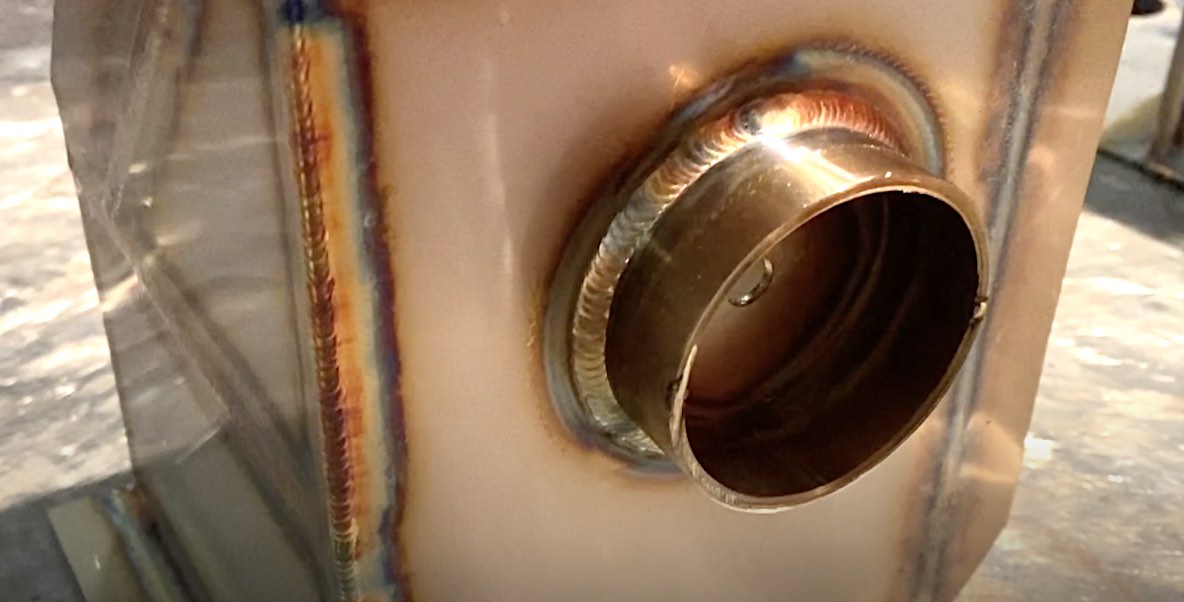

Phase 3....Aluminum and Stainless TIG projects

The last phase involved both Aluminum and stainless tig projects that also are required to be welded without changing positions of the welds.

The stainless project was last and requires the most time management skills because of the nature of stainless steel in retaining heat and also the gas purging requirements.

A good mix of butt joints, outside corners, and tee joints are designed into both the aluminum and stainless tig projects.

Again the competitors were permitted to use the welding machines to their fullest capabilities so I saw a lot of pulse tig going on on the stainless project.

The scoring on the aluminum and stainless tig process was strictly visual but fillet weld gages were used to verify minimum weld size and calipers were used to measure bead width variation.

The criteria for bead width variation is more stringent than most welding codes.

The bar is set high for these competitors and that is what will prepare them well for a career in welding.

Or anything other field for that matter... because the work ethic, skill of learning how to learn, and commitment to excellence they build on the journey to worldskills welding competition will transfer over into anything they do.

Did you know?..

There are over 800 videos over at welderskills.com from beginner stick welding to advanced TIG... to down and dirty repair videos on farm equipment...to 6G Pipe certification test videos.

Whether you are a student working on passing a welding test, hobbyist, or a working welder who wants to sharpen up, I want to encourage you to take the free 7 day test drive and get access to all the courses and over 800 videos.

Get in there and lets all get better together.

Its easy to sign up…and even easier to cancel with no hoops to jump thru.

Invest in yourself,

See you in there.

Jody