Weldtec Water Cooler, SW320 torch, and a Dynasty 280

see more tig welding videos

shop weldmonger.com for tig fingers and more

In this video I hooked up a Weldtec water cooler to my Dynasty 280dx tig welder.

I have been meaning to get this done for quite a while because using a 150 amp air cooled torch on a 280 amp welder limits what you can do.

I recently got the expansion card that will allow me to use all types of amplitude settings on AC and I want to be able to explore all the capabilities of the machine when it comes to thicker aluminum.

Why WeldTec?

Right before I retired from Delta TechOps, we hooked up several Weldtec Water Coolers to some new Dynasty 200 tig welders being set up to weld engine parts.

We tried using a different small compact tig cooler but they were just too loud.

When you are enclosed in a booth, you really notice continuous noise from a cooler.

The Dynastys were quiet with "fan on demand" so the extra cooler noise seemed unecessary.

The Weldtec is pretty quiet compared to others I have used like miller, Dynaflux, and Everlast.

That was in 2010 and they are still running fine as I write this here in July of 2019.

That is the main reason I chose to go with Weldtec.

Other reasons are:

- If I ever need to upgrade to a higher amperge cooler, I can just order a larger capacity tank that goes on the bottom.

- Replacement parts are readily available for Weldtec water coolers

- Its stainless steel and wont rust

SW320 speedway torch

There are several different styles of water cooled torches.

I have always preffered the #20 style becasue of all the cup and gas lens options it allows.

The SW320 torch is rated for 320 amps and my Dynasty 280 will never exceed the rating for the torch.

I also like the feel of the SW320 torch with the hump on the handle.

It lets me conrol the torch on small tubing where rotating the torch handle is needed in order to maintain the right torch angle.

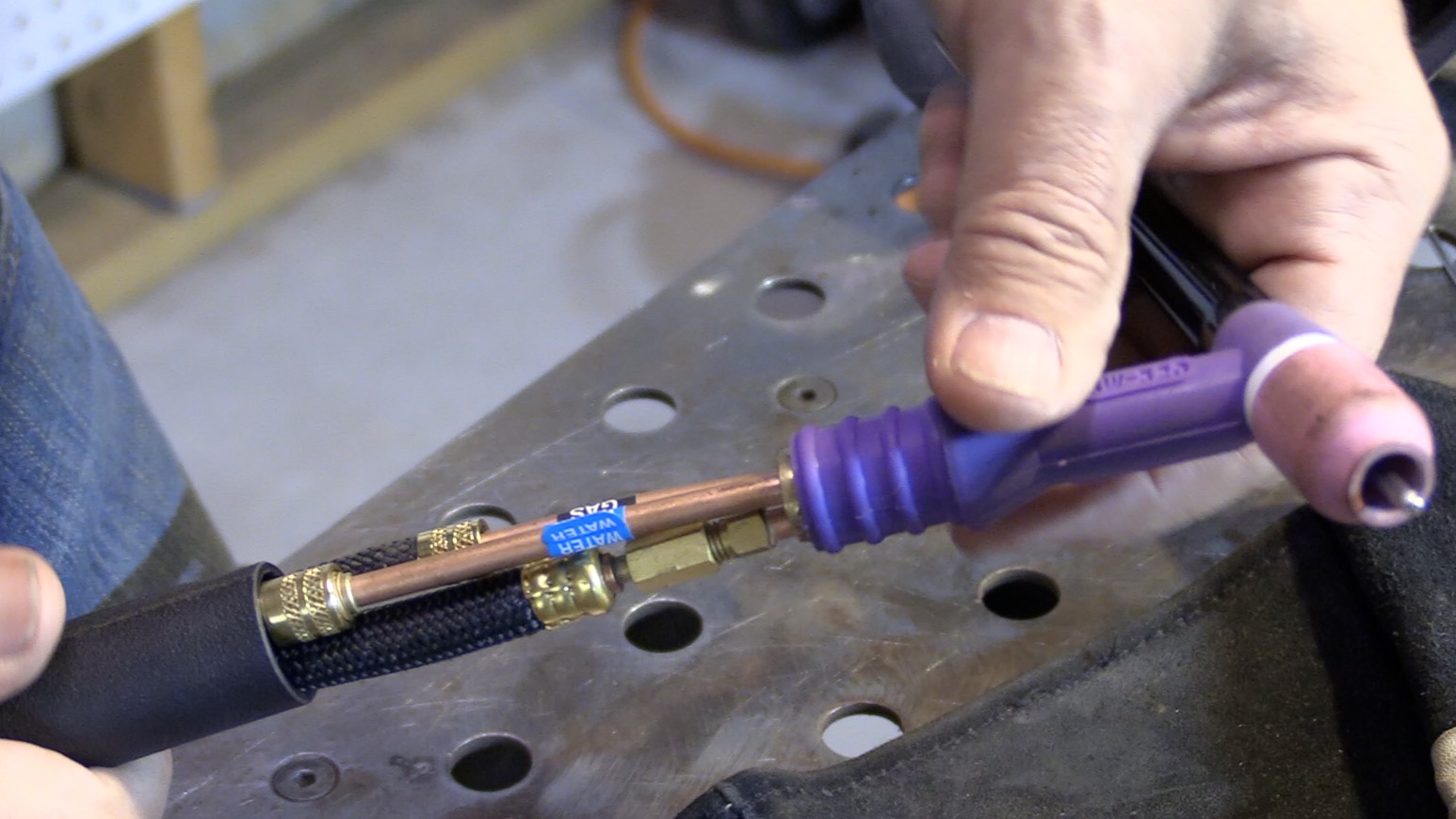

Dinse Adapter

Most newer inverter tig welders require a dinse adapter in order to hook up a tig cooler.

It would be great if one dinse adapter worked for all machines.

Sadly, thats just not so.

Some machines have a gas thru style dinse so its important to identify which style dinse your machine needs before hooking up a water cooler..

Once you identify which dinse adapter you need for your machine, hooking up your water cooler is pretty simple if you follow the instructions.

Its fairly simple if you follow the instructions...But it is possible to get it backwards.

The main thing to remember is that the water or coolant needs to reach the torch head first before the power cable.

you can see lots more information on weldtec water coolers, dinse adapters, and more at http://www.tectorch.com/