TIG welding-tig stainless steel

The Best Videos on TIG welding tig stainless steel on the web...

Sometimes stainless steels are welded without filler metal and the term for that is autogenous

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

For stainless steel kitchen and food processing equipment made from sheet metal, certain welds are made without filler metal. Some call it "fuse welding" but the official term for tig welding without filler metal is "autogenous"

Sanitary stainless tubing .063" wall thickness is commonly welded without filler.

One of the main objectives with welding stainless steel is to maintain the stainless properties.

Stainless steel is usually specified for corrosion resistance in environments where carbon steel will not last.

But if you use the wrong practices, you can destroy the corrosion resistance of stainless steels.

Here are a few things to avoid in order to keep stainless steel stainless.

- using carbon steel wire brushes or wire brushes that have been used on carbon steels

- keeping the base metal too hot for too long

- using grinding wheels that have been used on carbon steels

- welding stainless parts on a carbon steel surface

- not purging full penetration welds

Heat input, sensitization, and carbide precipition

Heat Input

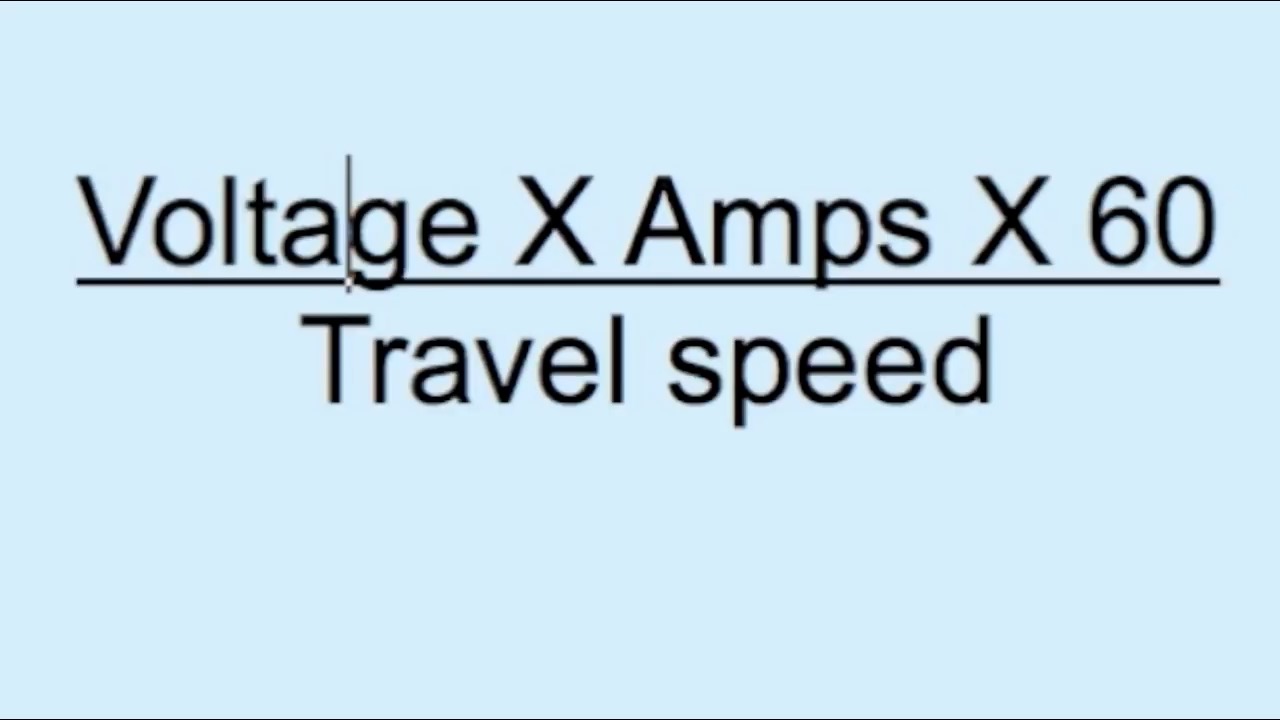

Heat Input in welding refers to the amount of energy provided to the weld area. It is a crucial factor in determining the weld's characteristics and quality. Heat input is influenced by the welding current, voltage, and travel speed, and can be calculated using the formula:

Heat Input=Voltage×Current×60 divided by Travel Speed

High heat input from either excess amperage or too slow a travel speed or both, can lead to several metallurgical changes in the material being welded.

Sensitization

Sensitization is a metallurgical phenomenon that occurs in certain stainless steels, particularly austenitic stainless steels, when they are exposed to temperatures in the range of 800°F to 1500°F (427°C to 816°C). During this temperature exposure, chromium carbides can form at the grain boundaries. Sensitization makes the stainless steel susceptible to intergranular corrosion, where the grain boundaries corrode preferentially.Carbide Precipitation

Carbide Precipitation refers to the formation of carbide particles, such as chromium carbides (Cr₃C₂), within the metal. In the context of welding, carbide precipitation occurs when the stainless steel is heated to the sensitization temperature range. The carbon in the steel combines with chromium to form these carbides, depleting the chromium content in the nearby regions of the metal.Relationship Between Heat Input, Sensitization, and Carbide Precipitation

Summary

- Heat Input and Carbide Precipitation:High heat input during welding can increase the temperature of the metal into the sensitization range (800°F to 1500°F).Prolonged exposure to these temperatures allows carbon and chromium to migrate and form chromium carbides.This precipitation occurs preferentially at the grain boundaries. So it is not temperature alone but time at temperature that causes sensitization and carbide precipitation

- Carbide Precipitation and Sensitization:The formation of chromium carbides depletes the chromium content in the areas adjacent to the grain boundaries.Chromium is essential for the corrosion resistance of stainless steel. When it is depleted, the areas near the grain boundaries become less resistant to corrosion.This condition is known as sensitization, making the material prone to intergranular corrosion.

- Heat Input and Sensitization:Controlling heat input is crucial to prevent sensitization.Lowering the heat input can reduce the time the metal spends in the sensitization temperature range, thereby minimizing the risk of carbide precipitation.Techniques such as faster travel speeds, lower current, and voltage settings can help manage heat input.

Heat input during welding significantly impacts the metallurgical properties of stainless steels. Excessive heat input can raise the temperature of the metal into the sensitization range, leading to the formation of chromium carbides at the grain boundaries. This process, known as carbide precipitation, depletes the chromium content in adjacent areas, resulting in sensitization and making the steel susceptible to intergranular corrosion. Controlling heat input is essential to prevent sensitization and maintain the corrosion resistance of stainless steels.