TIG Welding Stainless holes

Tips for TIG welding stainless holes

This video is about Tig welding stainless holes and how to prevent sugaring. ( technically known as granulation or excess oxidation).

Sugaring happens when molten stainless metal is exposed to air.

Aluminum or copper backing clamped tightly to the stainless sheet metal prevents sugaring and allows argon to be trapped along with providing a chill block to prevent distortion.

Settings and procedure

Tig welding stainless with aluminum backing requires a few more amps due to the heat sink chill effect of the aluminum.

but no more than 50 amps was needed to weld these 3 holes

amperage was set to 60 on the CK worldwide MT200 machine set to DCEN.

foot pedal was used to control amperage.

3/32" (i2.4mm) 2% lanthanated electrode

Jazzy 10 cup with 20 cfh argon

1/16" (1.6mm) ER308L stainless filler metal

Solid backing vs Argon Shielding

Sometimes solid aluminum or copper backing is all that is needed.

Sometimes solid backing is even better than argon shielding because solid backing serves as a chill bar too.

For solid backing, I have lots of different shapes of aluminum and copper that I have saved over the years and I use it for tasks like filling holes in stainless.

Argon shielding on stainless holes is best achieved with a small purge box.

An argon purge box is a quick and efficient way to get argon shielding on the back side of stainless for quick repairs like welding holes.

- First hole was welded with no backing

- Second hole was welded with aluminum backing

- third hole was welded with argon backing using a purge box.

Making a purge box

Here are some pretty old images showing one way to make an argon purge box.

I took them way back in 2007 before smart phones and I carried around a small Kodak digital camera.

The ones I made used stainless steel sheet metal about .040" to .063" thick.

A piece of 1/4" tubing runs the hole length of the box and has holes drilled every half inch or so.

The holes are facing the back so the argon diffuses better.

I used copper wool for the diffuser material but other materials work too.

I used perforated copper for the surface that will be held near the weld because stainless is more likely to weld to the back side whatever you are welding.

because the purge box uses 1/4" tubing, the clear fiber reinforced tubing that you find at big box store like home depot works fine.

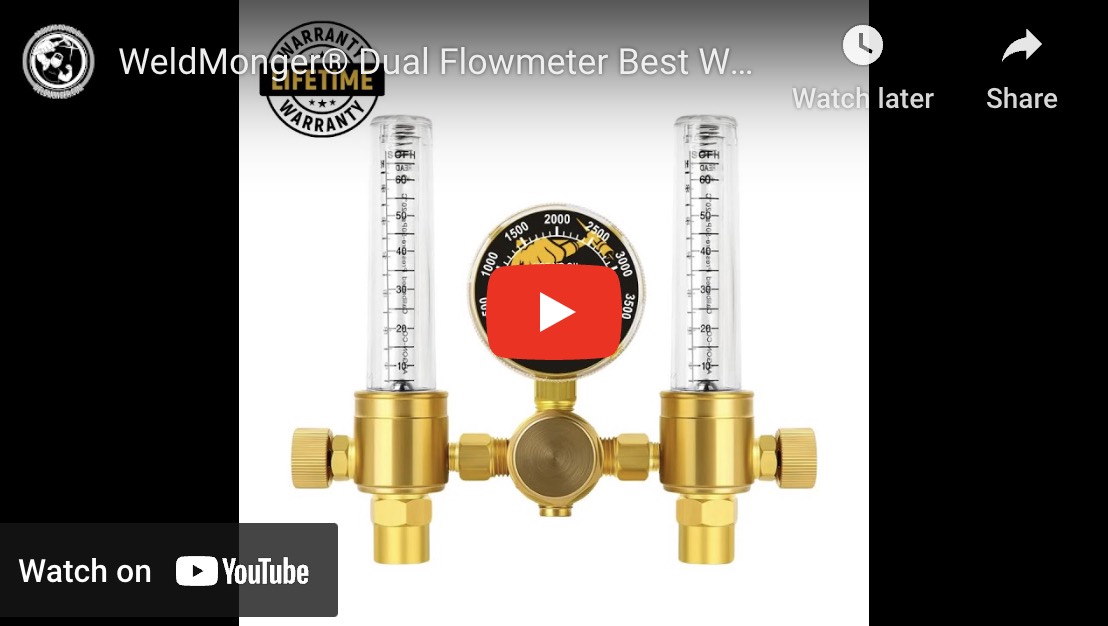

But the one thing you need to make all this happen once you make your purge box is a dual flowmeter.

...Or if you have 2 cylinders of argon, 2 single flowmeters will get the job done.