Piggy Bank Welding Project

This is part 2 of a piggy bank TIG welding project using aluminized exhaust tubing, hot rolled steel end caps, threaded pipe fittings, and some copper tubing.

IF you missed part 1 of this welding project you can find it here

In part 1 I tig welded/brazed some threaded pipe couplings on some end caps.

So now its time to cut the aluminized exhaust pipe and weld the end caps.

After that, I cut some copper couplings for legs.

Pulse settings for this Piggy bank welding project

visit weldmonger.com for tig welding supplies

For tigging the copper couplings to the aluminized steel, I found that using .7 pulses per second with 50% pulse on time and 20% background really kept the heat from getting out of hand.

when you weld a small piece of copper, at first, it takes a lot of heat to puddle.

But after a very short time, heat saturates the copper and it gets too hot. ….you have to back off the foot pedal to control the puddle.

but by using pulse settings of .7pps, 50% pulse time, and 20% background, it helped keep things very manageable without having to work the foot pedal much.

Again, I used silicon bronze for joining the copper pieces to the aluminized tubing.

Those same settings worked well on AC too. …with AC balance set to 95% EN and freq set to 250 hz.

I puddle a little nub on the rear cap as an easy holder for some 1/4" copper tubing and that made things go way quicker than trying to hold the copper tubing while trying to get a tack on it.

then I used the tig torch to heat and curl the tubing for the tail.

The last thing was to weld some eyeballs and ears.

I had a few small tabs left over from another job so I figured they might work for ears.

That little magtab really earns its keep around my shop. It makes tacking tabs a breeze.

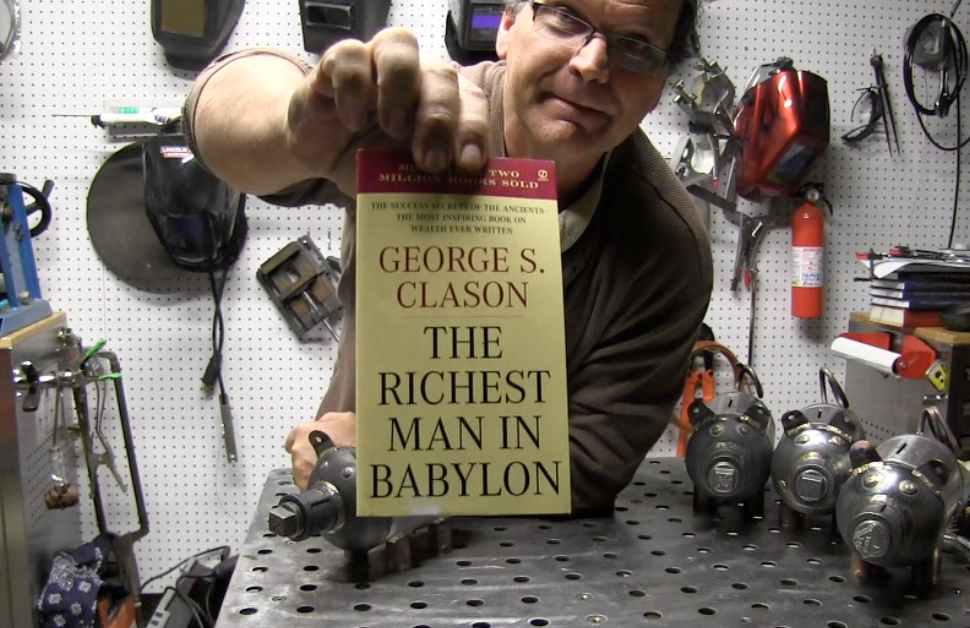

Ok, so here is why I went to such great effort to make these piggy banks.

My Dad gave me a copy of "Richest Man in Babylon" to me when I was a young man.

2 lessons that the book teaches are:

- Pay yourself first. …because part of all you earn is yours to keep…if you insist that it be so.

- Make work your friend.

Its funny how a little book can make an impact on you.

Both my Mom and Dad have been gone for a long time now, but I thank God I had parents who really cared about me.

They both tried to teach me lifes lessons without me having to go thru too many hard knocks.

I'll bet my Dad had no idea that I would remember his gift and now be passing it on.

But that is something I am thinking about and hoping my kids learn the lessons in the book and pass it on to their kids too.

more welding projects