Welcome to your Crash Course on down and dirty Welding Metallurgy.

Disclaimer...Everything in this Down and Dirty Metallurgy course is OVERSIMPLIFIED!!

Welding Metallurgy sounds about as exciting as Quantum Physics.

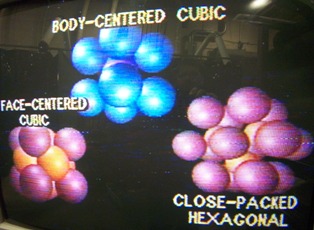

Would you like to learn all about body centered cubic, face centered cubic, and hexagonal closed packed crystalline structures?

Me neither!!!!!

The best welders I know don’t know a thing about microstructure of metals and you know what ?

They don't need to Know!!

Here is the one down and dirty thing you need to know in order to be a good welder, fabricator, and craftsman:

Are you ready? Don’t miss this!

Carbon steel, cast iron, low alloy steels like 4130 chromoly, and straight chromium stainless steel like 410 all harden from heating and then quick cooling.

Almost everything else does not harden from heating and quenching.

Did you hear what I said? I know it seems simple but honestly, if you understand this one thing, you will stand head and shoulders over 90 percent of the people you work with. Even the engineers and inspectors. I am serious here! I have worked with PhDs, and engineers for several years and I stand behind what I am saying here. Most of them are smart folks, but they are not welders and most of them just dont have a "hands on" feel for the affects of heat on metal.

Heat affects different metals in different ways but it’s really not all that complicated.

Welding produces enough heat to melt the metal so there will always be a heat affected zone next to the weld where the metal got really hot and then cooled pretty quick because of the relatively cool metal surrounding the weld. Think of heating up something red hot and then dunking it in a bucket of cold water. That’s what happens when you weld something. But it only happens in a narrow zone next to the weld.

Carbon steel, cast iron, low alloy steels like 4130 chromoly, and straight chromium stainless steel like 410 all harden from heating and then quick cooling.

Almost everything else does not harden from heating and quenching. If you don’t get this yet, read it again. And then again. And then again, And then again.

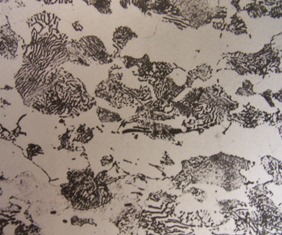

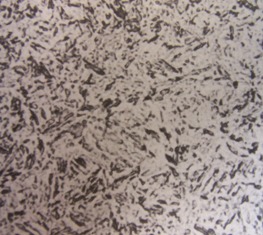

Check out These Pics of 4130 Chromoly before and After Heating and Quenching

Learn more about Tig welding 4130 chromoly

The Photo on the left is a Normalized microstructure. The 4130 chromoly was heated and then allowed to cool very slowly.

The photo on the right shows a totally different microstructure. A very hard and brittle one called martensite.

Ok... Here is the Key to Understanding Down and Dirty Welding Metallurgy!Here it is so you can read it again…. because this is the key to Down and Dirty Welding Metallurgy:Carbon steel, cast iron, low alloy steels like 4130 chromoly, and straight chromium stainless steel like 410 all harden from heating and then quick cooling.

Almost everything else does not harden from heating and quenching.

Neither Stainless or Aluminum harden from quick cooling.

Have you got it?.

learn more about welding steel

Custom Search

If you signed up for the 7 Day Crash Course, Be Sure to Check your Email for Your next lesson on Down and Dirty Metallurgy

Leave welding metallurgy and visit home page