Welding Cart Project part 5....done

One of the main reasons for building this welding cart was to be able to have 2 gas cylinders fastened securely at all times.

I like to have argon, as well as helium available to me so I can handle a wide variety of welding situations.

for

the back of this welding cart where the gas cylinders will go, I made 2

brackets out of 1/8" thick (3.2mm) cold rolled steel.

I

had several pieces of 11ga cold rolled in my shop that were 2x6 inches long so I decided those

pieces would make a pretty decent rack for 2 gas cylinders....all I had to do was cut a few pieces down to 4.25" for the end pieces.

So

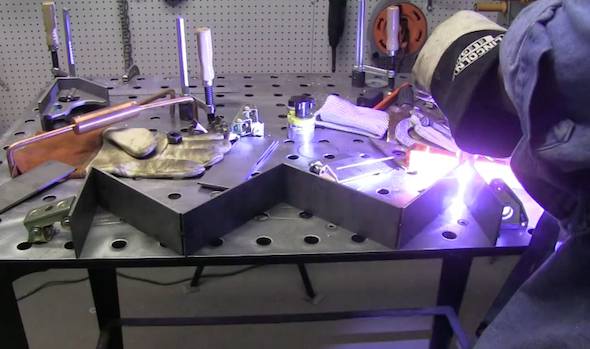

for this video, I am going to fabricate a rack for 2 gas

cylinders....and to do that I used some small magnets to hold the pieces

on the table so I could get a few tack welds on them.

each piece is 6 inches long and the 2 pieces on the ends are 4.25" ...and the whole assembly is just a bit over 17 inches.

Since

the cart itself is 18 inches wide, that leaves just the enough room for

a nice fillet weld on the outside edges of the assembly.

Tig welding the outside corners on the welding cart cylinder bracket...using aluminum backing

For tig welding outside corner joints on carbon steel or stainless

steel, you will get a better looking weld with less discoloration and

less distortion by using a heavy piece of aluminum for backing.

A

heavy chunk of copper works even better but copper scrap is expensive

and harder to find than aluminum and aluminum works almost as well.

This trick is especially handy for stainless steel welds.

I

save every piece of aluminum I can and keep them on hand to use as

backing and for chill bars. Sometimes I go to a lot of effort to clamp

aluminum backing in place but for stainless steel sheet metal, it is

worth the effort....the back side of the weld usually comes out almost

as if I had used argon backing gas....and the puddle flows better too

from less oxidation being pulled in from the back side.

Granted,

for these carbon steel pieces, backing was really not needed but I used

backing anyway because it only takes a few extra minutes and the welds

usually turn out much better.

After the pieces were all welded on the table, I drilled some 3/8" holes in the end pieces and then welded them to the cart.

The 3/8" holes are for eyebolts that will hold the chains that secure the gas cylinders to the welding cart.

Why a bracket for 2 cylinders?

Previously,

if i wanted to mix helium and argon for tig welding on thick aluminum, I

would roll a tank of helium up close to my welder and fasten it to the

cart using a big Zip Tie or short piece of chain.

What I want to

have is both argon and helium available all the time where I all need to

do is turn on a valve to mix argon and helium.

There are 2 situations where I need to have helium available:

1. for mixing helium with argon for tig welding on AC on thick metal. ( thicker than 1/8" .125" or 3.2mm)

2. for welding aluminum on DC with pure helium.

I will go into both of these topics briefly below and more in depth in later articles....

and explain how to do each in future videos ....stay tuned.

For tig welding aluminum on AC,

mixing even 20-30% helium in with argon makes a big difference.The

aluminum puddles immediately, and it just welds cleaner and

better....and if you have ever welded thick aluminum with pure argon,

you know that it can take several seconds for the metal to soak enough

heat to establish a puddle. With helium mix, puddling is almost

immediate even on really thick aluminum. That is because helium provides

a hotter arc.

For DC welding aluminum, pure helium provides a hot enough arc to break thru aluminum oxides ...if you do everything right...its pretty finicky.

Some think that DCEN tig welding aluminum is for emergency situations

only....that high quality welds cannot be made using DCEN and pure

helium. Thats not true. Its finicky, but in the hands of the right person, its amazing what it can do on thick aluminum.

DCEN tig welding on aluminum can make high quality welds.

DCEN provides deep penetration and can make a good looking weld but like I said it takes a bit of finesse.

( I am currently working with a real pro at DC aluminum welding and hope to have a good video out very soon)

One area where welders fail when trying to weld aluminum on DC is not

using adequate gas flow. Since helium is lighter than air ...and argon

is heavier than air, it takes a lot more cfh to properly shield a weld.

If you dont take that into consideration, you wont get good shielding

and you wont get a decent weld.

A tight arc, a gas lens, a clean

sharp tungsten, and keeping the hot tip of the rod shielded under the

cup all help in making a good tig weld with DCEN and pure helium.

So Back to the welding cart....

For a tig welding cart to be really useful for me, it needs to have a spot for 2 gas cylinders. One for argon, and one for helium.

See more welding projects like this welding cart