Welding 4130 chromoly with a 400f Preheat

scroll down for videos on tig welding 4130

- HOME

- Tig Welding 4130

- Welding 4130 Chromoly

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

Check out Tig Fingers, Furick Cups, kits, and more...click here to visit the store

more videos on tig welding 4130 chromoly

dual flowmeter for purging

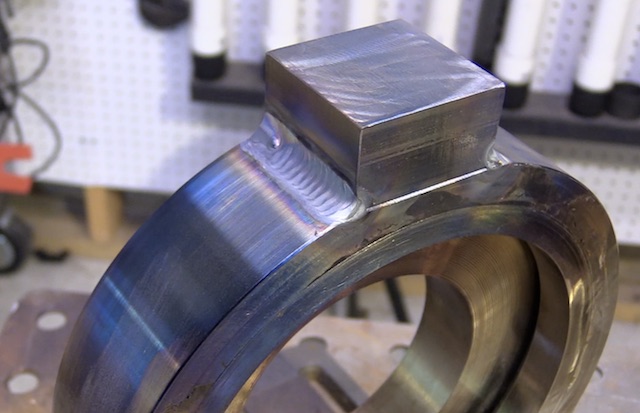

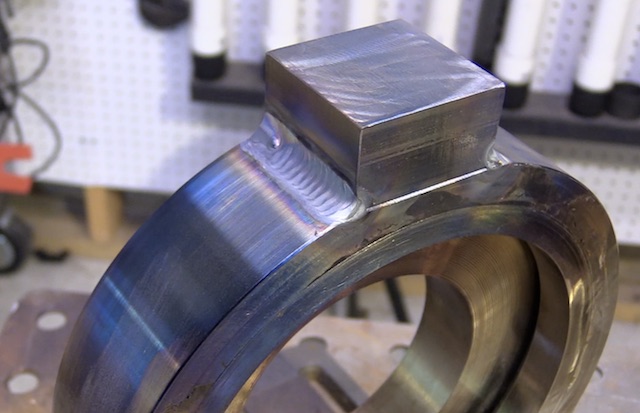

A hot job came in the shop the other day...

and it involved tig welding some pretty thick chunks of 4130 chromoly.

my machinist friend and job shop owner needed a thick piece of 4130 chromoly steel welded in order to meet a customers deadline.

So I thought I would bring you along with me.

It was a simple job, but there are still a few things to talk about...

like...

Filler metal selection for tig welding 4130 chromoly, preheat, and more

A quick talk with my friend and I learned that this part would be black oxide coated after welding and stress relief. (I made a video a while back showing the black oxide process)

That meant that I needed to weld it with a rod that would respond to black oxide coating.

I might have chosen an ER309 filler for this job but ER309 filler metal contains too much chromium and will not blacken the same as the 4130 base metal.

I also learned what the part does in service. and that it will be load tested to 900 lb.

900 lb is not that much for 2 - .250" leg fillet welds so that was not really a concern as far as matching filler metal to match the strength of the base metal.

And, the part was only going to have a furnace stress relief type heat treatment ...not a strengthening heat treatment....so using 4130 filler material was not a requirement.

So I chose er70s-2. and a 400f preheat

er70s-2 wire will blacken, and will provide a ductile weld that is unlikely to crack.

I used 2 passes on each side to meet the .250" fillet weld requirement on the drawing....and I kept the heat above 400f during the whole welding operation.

Then I reheated the entire part and let cool slowly to room temperature before delivering the part.

Welding Procedure for Tig Welding 4130 chromoly

Base Material Type/Thickness. 4130 chromoly / 1-1/4" thick

Prep Method - machined surface, acetone wipe only

Filler Metal Type/Size - ER70S-2 3/32". (32mm)

Tungsten size and prep 3/32" (2.4mm) 2% lanthanated blunt taper 60 degree

Gas Type and Flow Rate - argon 25cfh

Cup size #12 clear furick cup

Current/Polarity 160-170 amps DCEN

Length of Arc. - 3/32" (2.4mm) or less

Angle of Travel 15-20 degree

Manipulation/Technique - move, pause, dip for first pass, lay wire wave second pass

Speed of Travel -6-7 inches per minute

preheat - 400F min

- HOME

- Tig Welding 4130

- Welding 4130 Chromoly

Similar project with AISI 4140 and preheat

grab a tig finger at weldmonger.com

A few years ago, I welded a part for this same job shop owner made out of 4140 steel.

4140 is very similar to 4130 except that has a bit more carbon content and therefore sometimes requires a higher preheat.

In this video, I used a 500f preheat. First, I warmed the part up on a propane cooker, and then I used a rosebud torch to reach over 500f.

These parts were a tight fit so I heated the part with the hole first, then inserted the round part and heated it all to around 550f so that I could be sure it was at least 500f before welding.

I kept the temp up to 500f until welding was done, then reheated and let cool slowly.

I chose er70 filler rod for these parts also for the same reasons as the 4130 part...black oxide coating, and because the strength was taken care of with smart design.