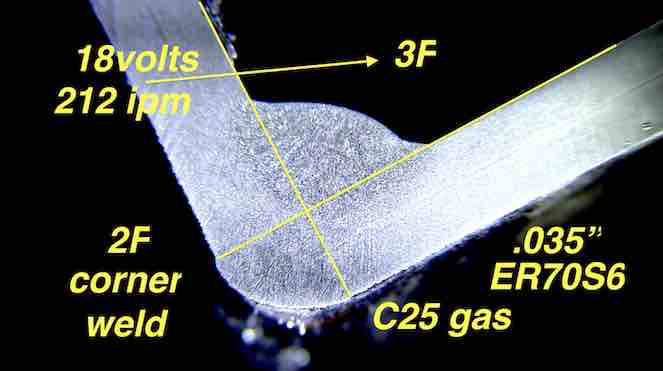

Uphill MIG welding settings along with a 2F horizontal outside corner joint

- HOME

- MIG WELDING

- Uphill Mig Welding Settings

learn more about the MIG 180 at weldmonger.com

I think of my Mig180 mostly as a Great Little MIG Welder with a great arc and nice small mig gun that feels great in my hand... but it also Stick welds, and even comes with a spool gun for aluminum.

just look at all that comes with it... That is a lot of bang for the buck!

Uphill MIG welding refers to the welding position where the weld joint is positioned at a vertical and upward angle relative to the welding direction.

In contrast, flat position refers to when the weld joint is horizontal or parallel to the ground. The welding settings for uphill are usually lower than for flat or horizontal position.

Voltage and Amperage: Uphill welding generally requires lower voltage and wire speed settings compared to flat position welding. This is because uphill welding involves gravity and requires a bit less heat input to get adequate penetration and fusion in the joint. The lower voltage and wire speed settings help to avoid excessive convexity in the bead due to gravity pulling down on the molten puddle.

Downhill Mig is much quicker and easier but once you get to around 3/16" thick, downhill short arc mig welding just doesn't penetrate enough.

It is slower and more difficult to get a good looking weld going uphill with short circuit mig welding....but its the way to go on 1/4" and thicker for anything important.

- Travel Speed: In uphill welding, the travel speed tends to be a bit slower compared to flat position welding. Slower travel speed allows for better control over the weld puddle and helps ensure good penetration provided a technique is used that plays the arc to the leading edge of the weld puddle.

- Gun Angle: The angle at which the welding gun or torch is held can also vary between uphill and flat position welding. In uphill welding, the gun angle can be dead nuts 90 degrees or slightly leaned back a bit.

- Shielding Gas Flow: The flow rate of the shielding gas can also differ between uphill and flat position welding. Uphill welding often requires a slightly higher shielding gas flow rate to provide adequate protection to the molten weld puddle. nozzle diameter also determines the gas flow rate needed.

- Stickout: with short circuit mig welding, a short stickout helps a lot with vertical uphill welding. some nozzle tip combinations have the contact tip recessed way back in the tip resulting in a long stickout. I sometimes trim the nozzle if I cant get the right nozzle tip combo. I really like the contact tip to be flush with the nozzle for short circuit mig and I find it really helps.

Cleaning mill scale prior to mig welding

Cleaning mill scale prior to MIG welding is an important step to ensure proper weld quality and fusion. Mill scale is a layer of oxide that forms on the surface of steel during the manufacturing process. It can really hinder fusion and penetration on mig welds.

Here are a few methods you can use to clean mill scale before MIG welding:

- Wire brushing: Use a wire brush or a wire wheel attached to an angle grinder or a drill to remove the mill scale. This method is somewhat effective for light to moderate mill scale found on square tubing.

- Grinding: If the mill scale is thicker or more stubborn, you can use a grinding wheel or abrasive disc to remove it. An angle grinder with either a hard rock or flap disc can be used for this purpose. There are hard rocks designed for mill scale like Walter flex cut mill scale wheel and masonry hard rocks can work well too.

- Chemical treatments: There are various commercially available chemical products specifically designed to remove mill scale. These products typically require applying the chemical solution to the surface and allowing it to react with the mill scale before rinsing it off. Follow the manufacturer's instructions for proper usage and safety precautions.

After cleaning the mill scale, it's helpful to remove any remaining debris, such as dust, oil, or grease, from the surface. Use a clean cloth, solvent, or degreaser to ensure a clean and contaminant-free welding surface.

Remember to wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a respirator if necessary, when performing any of these cleaning methods. Additionally, always follow proper safety guidelines and adhere to the instructions provided by equipment manufacturers and chemical product manufacturers.

It's worth noting that the ideal method for mill scale removal may vary depending on the specific application, material thickness, and available resources. If you're unsure or dealing with a complex project, consult with a welding professional or expert for guidance.

Shielding gas for uphill mig welding settings - short circuit mig welding

The most common shielding gas used for short-circuit MIG (Metal Inert Gas) welding is a mixture of 75% Argon and 25% Carbon Dioxide, commonly known as C25 or 75/25. This gas mixture provides a good balance of arc stability, weld penetration, and spatter control. It is suitable for welding mild steel and some low-alloy steels. The high Argon content helps stabilize the arc and promotes good weld bead appearance, while the Carbon Dioxide enhances the arc heat and penetration.

Pure Co2 is also a good option for short circuit mig welding but the ranges for voltage and wire speed are tighter...getting the sweet spot settings dialed in with Co2 gas can be a bit more difficult.