TIG WELDING THIN CARBON STEEL SETTINGS

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

- HOME

- WELDER SETTINGS

- Tig Welder Settings

- Tig Welding Thin Carbon Steel

.023" thickness box cutter blades tig welder settings

thin carbon steel like .023" thickness is best welded using small diameter tungsten electrodes like 1/16" or even .040".

But if all you have is 3/32" tungsten, then sharpening the tip like a needle helps with low amp starts.

18ga .040"-0.048" Carbon Steel outside corner without chill bars TIG settings

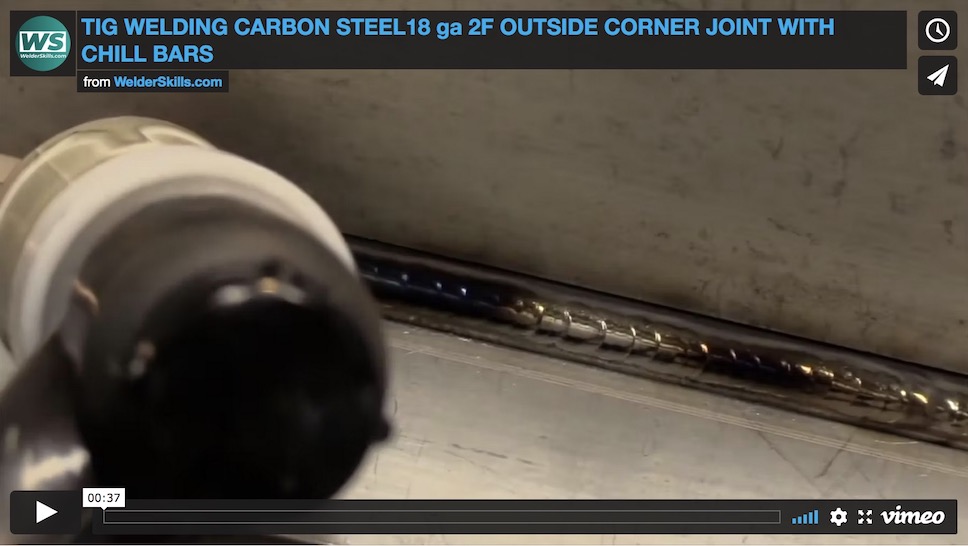

18ga carbon steel outside corner joint using Chill Bars settings

18 ga carbon steel .038" 1G test settings

welder settings for 18 ga lap joint carbon steel

thin wall .038" tube pulse settings on turntable

thin wall .038" tube welded to washer without pulse on turntable

.055" wall square tube tig welder fillet weld settings

.055" wall coped tube joint tig welder settings

.063" wall carbon steel tubing settings for carbon

tig welder settings for laywire technique on thin wall .063"tubing

pulse settings for tig welding .080" carbon steel corner

General tips for tig welding thin carbon steel...

- for the best crisp low amp arc starts, use the smallest diameter tungsten electrode that is practical.( if all you have is a 3/32" then a needle sharp point with a long sharp taper helps)

- When filler metal is required, use the smallest diameter that is practical. ( you can also use a piece of er70 small diameter mig wire)

- aluminum blocks for chill bars can help a lot in removing heat and preventing distortion

- happiness is a tight arc length

- keep your tungsten sharp...if you dip it, resharpen

- pulse settings are shown in several of these videos on tig welding thin carbon steel