Tig Welding Stainless Steel Settings

scroll down for links to various stainless weld settings

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

- HOME

- WELDER SETTINGS

- Tig Welder Settings

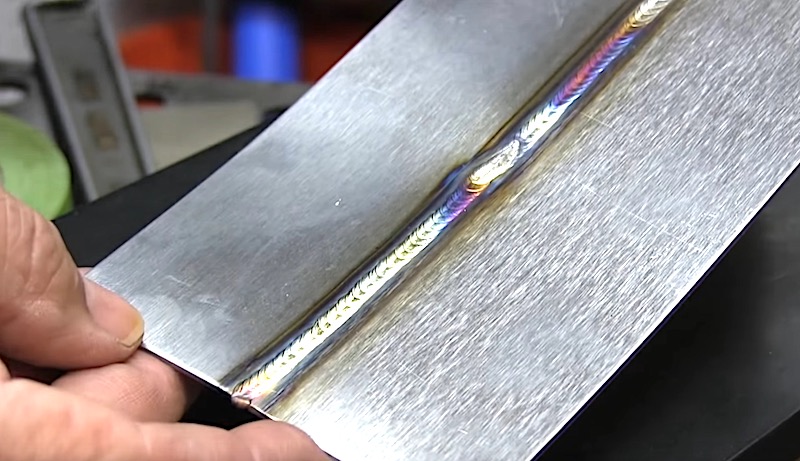

- Tig Welding Stainless Steel Settings

settings for tig welding stainless steel .120" wall coped tubing

stainless steel shaft keyway repair settings

settings for tig welding stainless steel 16 ga lap joint 2f

tig welding stainless steel hole fill repair in .050" thickness

tig welding stainless steel sanitary tubing purged .063" thickness

tig welding stainless steel 11ga outside corner 2f fillet weld settings

stainless steel 18 ga 2f corner joint settings

settings for tig welding 16ga stainless steel outside corner joint

tig welding stainless steel 11ga sheet to pipe pulse tig settings joint

walking the cup on 1/2" wall stainless tubing

walking the cup on 1/4" plate using er309 stainless filler rod

carbon to stainless purged pipe root er309

carbon to stainless pipe hot pass settings

Tips for TIG Welding Stainless Steel

- Heat builds up in stainless steel due to low heat conductivity and once heat builds up, it is hard to outrun.

- 3 Second rule...get the puddle established and moving within 3 seconds

- Travel speed is one of the biggest factors when it comes to overall heat input...a slow travel speed with low amps can often overheat stainless more than a higher amperage with faster travel speed.

- Heat sinks in the way of fixturing or chill bars can help a lot to remove heat from stainless and prevent heat from building up.

- A gas lens setup helps. TIG cups like the Jazzy10 make a big difference and help prevent discoloration

- keep the hot tip of the filler rod shielded in the argon and snip the end between restarts if the tip gets discolored.

- purge the back side with argon on full penetration welds...when not possible, often copper or aluminum backing can help trap argon from the torch and provides adequate results.

- Use only stainless steel wire brushes that have only been used on stainless (a good practice is to label and keep your stainless brushes stored separately from carbon brushes.)