TIG Welding Stainless Pipe Root and Hot pass in 2G with purge

Scroll down for Videos

- HOME

- Tig Welding Stainless

- Tig Welding Stainless Steel

- Tig Welding Stainless Pipe

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

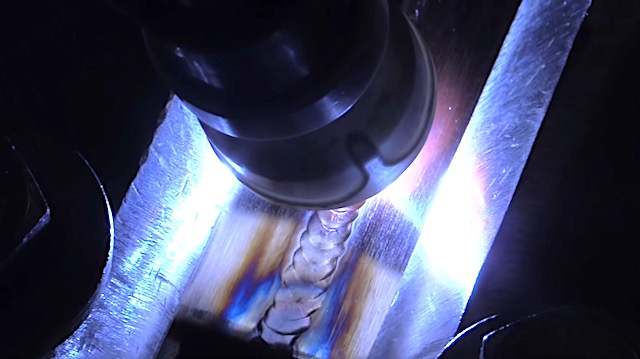

This video shows the difference between bridge tacks and penetrated tacks along with purging and root pass techniques with clear arc shots and settings.

I get a lot a questions about the tape I used for purging and it is high temp tape for powder coating and works great for purging stainless pipe so that you can see thru and inspect tack welds and root penetration.

Stainless steel requires argon shielding for the penetration side of open roots and one of the best ways to get purge gas is with a dual flowmeter.

A dual flowmeter lets you get a purge without 2 argon cylinders and that can be a pretty big deal if you are toting them up stairs or from the truck into the job site.

Sanitary Stainless Welding

Another type of tig welding stainless pipe is sanitary tubing.

Sanitary tubing is used for breweries, hemp processing, food and beverage, and pharmaceutical applications.

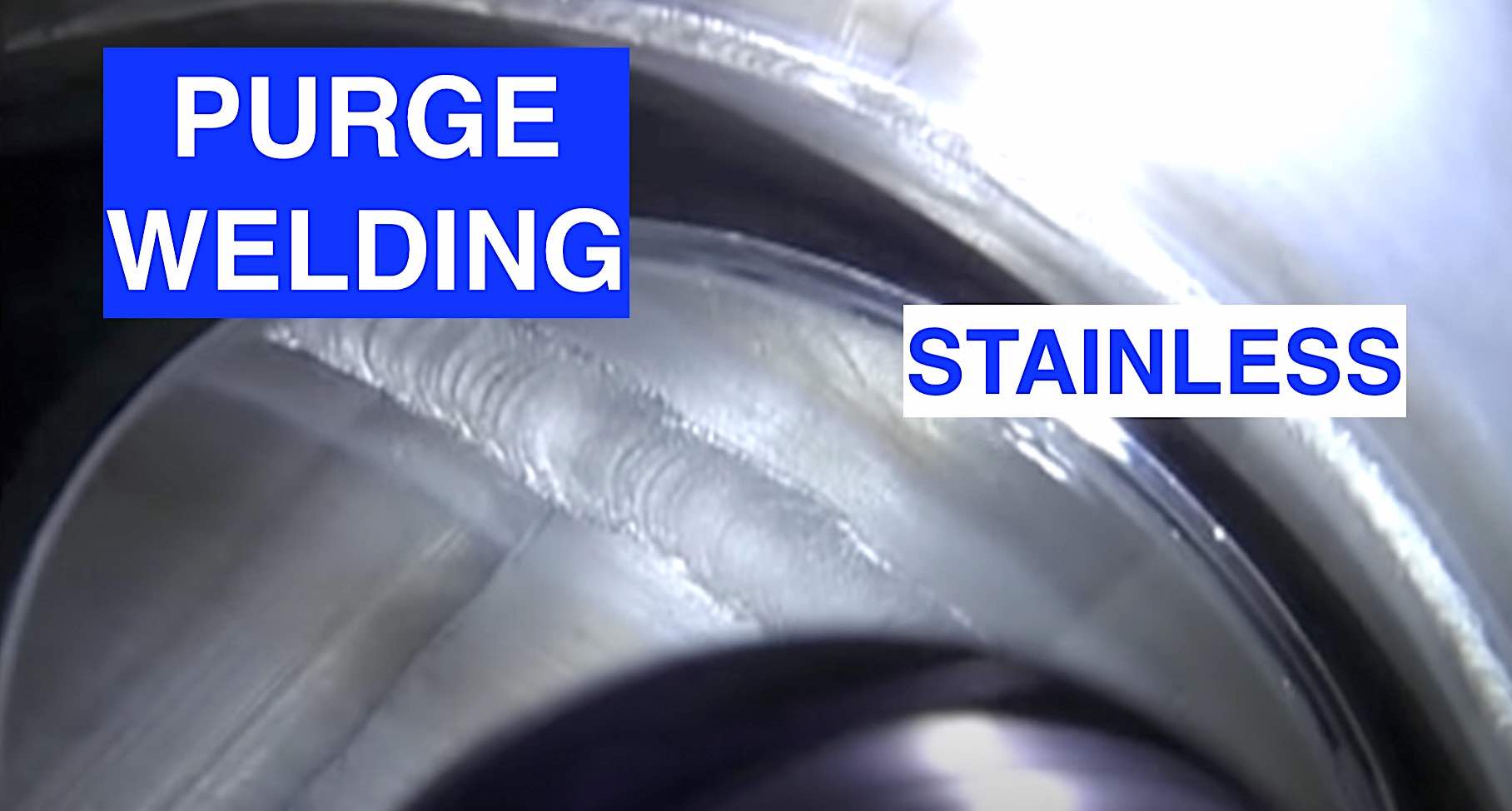

With sanitary stainless welding, the quality of the inside of the root pass is the main thing.

It must be silver and free from an crevices that might trap bacteria.

Getting a perfect purge is the way to get that high quality penetration that wont trap bacteria.

Sanitary stainless is mostly done without filler metal.

The fancy word for that is autogenous welding.

TIG Welding Stainless Pipe flange to pipe

In this video both walking the cup and freehand techniques are shown while welding a stainless flange to carbon steel pipe using ER309L tig rod.

Arc shots show technique and exact settings and techniques are shown.These same settings will work on stainless pipe welds whether you are using a scratch start rig or a foot pedal.

best practices for tig welding stainless pipe

- amperage will usually be about 2/3 what is used for carbon steel

- use only stainless wire brushes that have been dedicated to stainless steel

- use only abrasives that have been dedicated to stainless

- make sure purge is right before welding the root. check all joints and vents to make sure they are properly taped and allow enough time for the argon to completely displace any pockets of air inside the pipe