Tig Welding Repair on a C Clamp

A friend of mine accidentally walked off and left a c clamp "stack cut" situation for a little too long.

He asked me to weld it for him so "tig welding a C clamp" is what this weeks video is about.

But...this welding repair got me to thinking...and that is always dangerous.

How many folks would think that this C clamp is cast iron?

It does have kind of a Cast look to it ....but it is definitely Not cast iron.

But how do you know for sure when something is cast iron?

IF only there were a simple down and dirty test?

Watch the video and you will see how I check for hardenability of a metal before I attempt a weld repair.

Ok, I will go ahead and spell it out here too.

Spark testing using a grinder is one piece of information that can help you identify metals.

But spark charts do not always a give a clear answer.

The surest method I have tried is to use a tig torch to puddle a very small area very quickly.

What

happens when you do that is the metal exceeds any transition

temperature required to harden and then the surrounding cool metal acts

as a heat sink to quench the puddled area fast.

Then use a file on it. If it cuts easily, its not cast iron...and its not very hardenable.

If it does not cut at all, and it has the appearance of cast iron. It most likely is.

Cast iron has a whole bunch of carbon.. upwards of 2% and sometimes way more.

Compare that to mild steel which only has .1 to .2 percent. thats

point 1 to 2 percent ...one to two tenths of a percent. So cast iron

has more than 10 times the carbon content than mild steel does.

Cast

iron has so much carbon that when you puddle it with a tig torch for

just a half second, it will harden that spot a lot. Thats why we

preheat cast iron for welding...to slow the cooling rate to prevent

excessive hardening.

But like I said...the C clamp is definitely NOT made from cast iron. The tig puddle test confirmed it.

Besides,

Cast iron would be a poor choice for a material to make a C clamp

anyway. It would break without warning if you stressed it too much.

So now that I know that. All I need to worry about is prepping the

metal by grooving a V with a grinder and by sanding to bright metal all

around the joint.

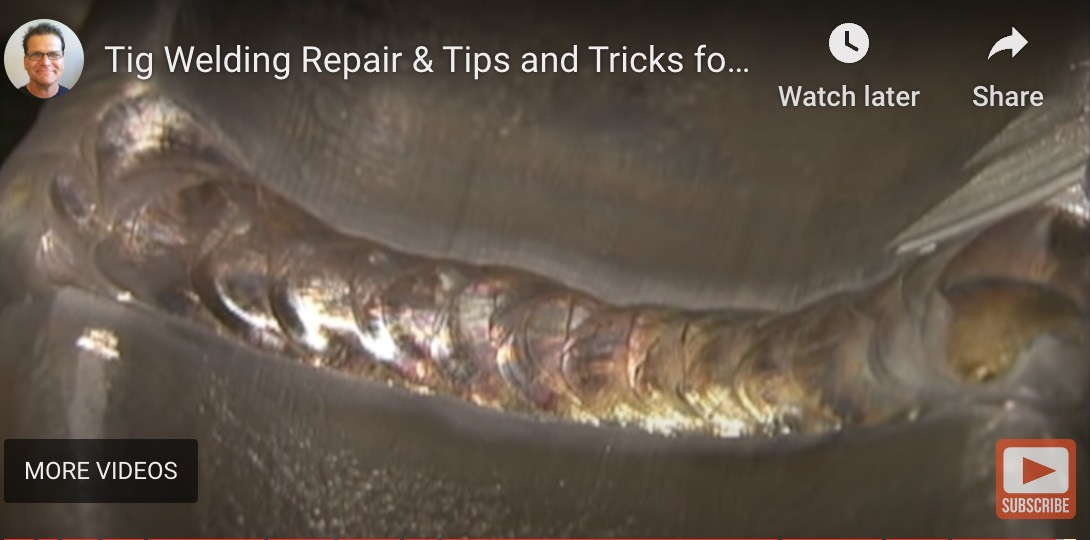

I tig welded it all the way out using several passes of 309 ss tig wire.

309 stainless tig welding wire is a good all around maintenance rod. I have

at least one detractor in NZ who says using 309 on steel is a

"crutch". That may be true but sometimes its a dang good crutch.. and

it is often a good choice for quick repairs like this when you are not

sure exactly what grade of steel you have.

exit this tig welding repair video page and see more tig welding videos