TIG Welding Steel and Heat Input

- HOME

- TIG WELDING

- Tig Welding

I just watched a YOUTUBE video on Tig welding steel on the

lincolnelectric channel and I thought I would continue that conversation

with a video of my own.

The welding instructor in the video is Karl Hoes and he did a great job of breaking down the subject of heat input and affects of travel speed on heat input.

I had the pleasure of meeting Karl while on a visit to the Lincoln Electric welding school and so it is no surprise to me that he did such a good job explaining heat input in that video. Thats just the kind of welding instructor he is. Able to explain things in a way that makes sense to students as well as a youtube audience.

As I watched the video, I had some ideas on some things I would like to add in a video of my own... and so that is what I did.

The fact that you are reading this at this very moment tells me you are interested in learning more about welding. Heck, I do too...even after over 36 years in the trade.

I am always looking to learn something...And I did learn a few things while shooting this video.

1. I learned to always check gas lenses. ( had had a defective one and saw some sparks in the film while editing it)

2. travel speed makes more difference than I thought. I knew it was a big player, but I learned in most situations, it makes more difference than voltage or amperage.

3. because I was setting the machine and then going "full pedal" I learned that 80 amps is about the lowest amperage I would ever use to weld 11ga cold rolled steel...but 140 worked great as long as I could keep up with filler rod dips.

4. Pulsing at 200 pulses per second was interesting but that will come in a future video

So here is how this heat input video played out...

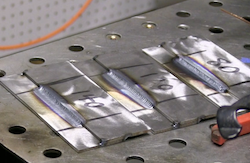

- I cleaned several pieces of 11 ga steel with a flap disc so that the bare bright metal would not only weld better but would show distinct heat zones.

- for the first joint, I set the tig welder to 80 amps. A low setting for this thickness of .125" or 3mm. But I wanted to go low to exaggerate the effect.

80 amps required an extremely slow travel speed and it took me a full minute to travel 3 inches. so the travel speed was 3 inches per minute. - For the second joint, I increased amps to 120 and as expected that amperage was just about right. That old one amp per thousands ( 40 amps per 1 mm) really holds true in carbon steel up to around 160 amps.

This time it took was 35 seconds... much less time to travel the 3 inches than the first joint and the heat zone was smaller than the weld done at 80 amps. - For the 3rd joint, I bumped amps up to 140, and had to increase travel speed to keep up, it only took 25 seconds to travel 3 inches...and the heat zone was smaller than either of the other two previous welds...very interesting.

I wondered what would happen if I increased amps to 160 and then just ran over the wire so that is exactly what I did next and that weld took 15 seconds and guess what? You guessed it...a narrower heat zone.

Wow. I used twice the amperage than the first weld and wound up with less heat input.

So what is the takeaway in this video on Tig welding and heat input?

Well heat input is not something to be

afraid of. But it is something to figure in to a welding procedure

because heat affects different metal in different ways.

- the cold rolled steel in this video would be affected from excessive tig welding

heat input because the cold worked metal would lose strength from

recrystallization of the elongated grains.

- a low alloy high strength steel might be affected by either too much or not enough heat input. Not enough heat input might cause the heat affected zone to develop hard brittle areas while too much heat input might cause grain growth, or softened areas.

- On a heat treated aluminum alloy like 6061 t6, excessive heat input will weaken the heat affected zone severely .

- On 304 stainless, excess heat input can cause carbide precipitation.

Heat Input affects metal properties

So the main takeaway from this video is this...,

Heat affects different metals in different ways.

That

is why welding procedures are used for critical welds. A proven weld

procedure will help to keep heat input within a range that produces

welds with acceptable properties.