Tig Welding Carbon Steel

This page is about TIG welding carbon steel.

From beads on plate, to padding beads on plate, to corner, lap, and tee joints.

3 Mistakes to Avoid when TIG welding carbon steel

- Using an arc length that is too long

- Too much torch angle

- not shielding the hot tip of the filler rod

- Clean your metal...ok thats 4 but it's important

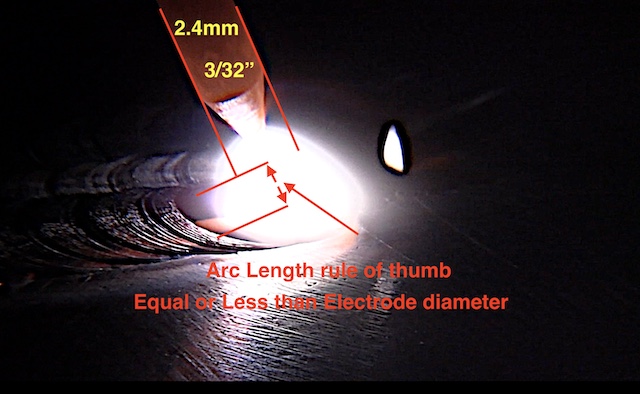

ARC LENGTH

For tig welding carbon steel an arc length that is equal to or less than the electrode diameter is a good rule of thumb.

In the image above you can see that the arc length is slightly less than the 3/32" (2.4mm) tungsten diameter.

The thinner the metal, the tighter the arc should be. Generally speaking

Keep in mind that is just a rule of thumb... there are always exception in welding.

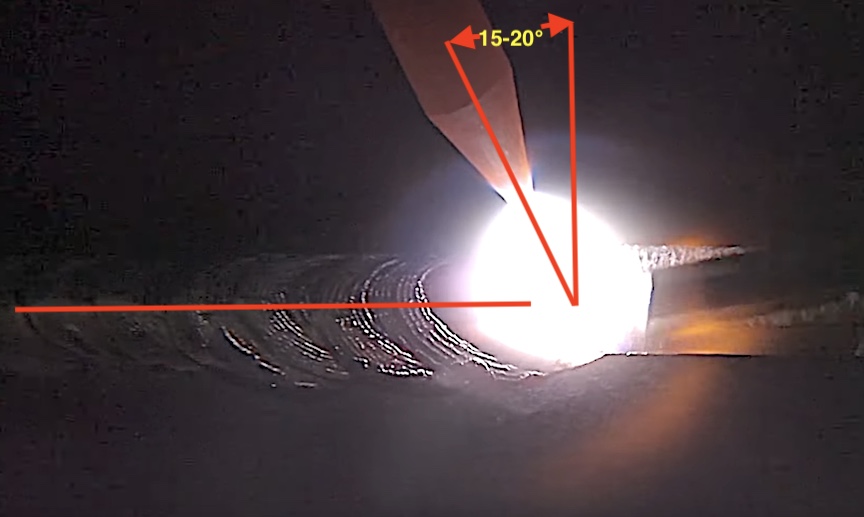

What is a good torch angle to TIG welding carbon steel?

Shoot for only about 15 degrees and just know that torch angle can be very forgiving provided your arc length is tight enough.

There are also situations where a strange torch angle is the only way to get the thing welded.

For those times, you just do what is required.

But for wide open tig welding jobs on the workbench where nothing is in your way, maintaining a consistent torch angle of about 15-20 degrees works well.

Why worry about shielding the hot tip of the filler rod?

Most every carbon steel or alloy steel weld puddle flows better if the puddle remains free from excessive oxidation.

Oxides in the weld puddle make it sluggish.

Keeping the hot tip of the filler rod shielded in the argon envelope prevents adding oxidation to the puddle.

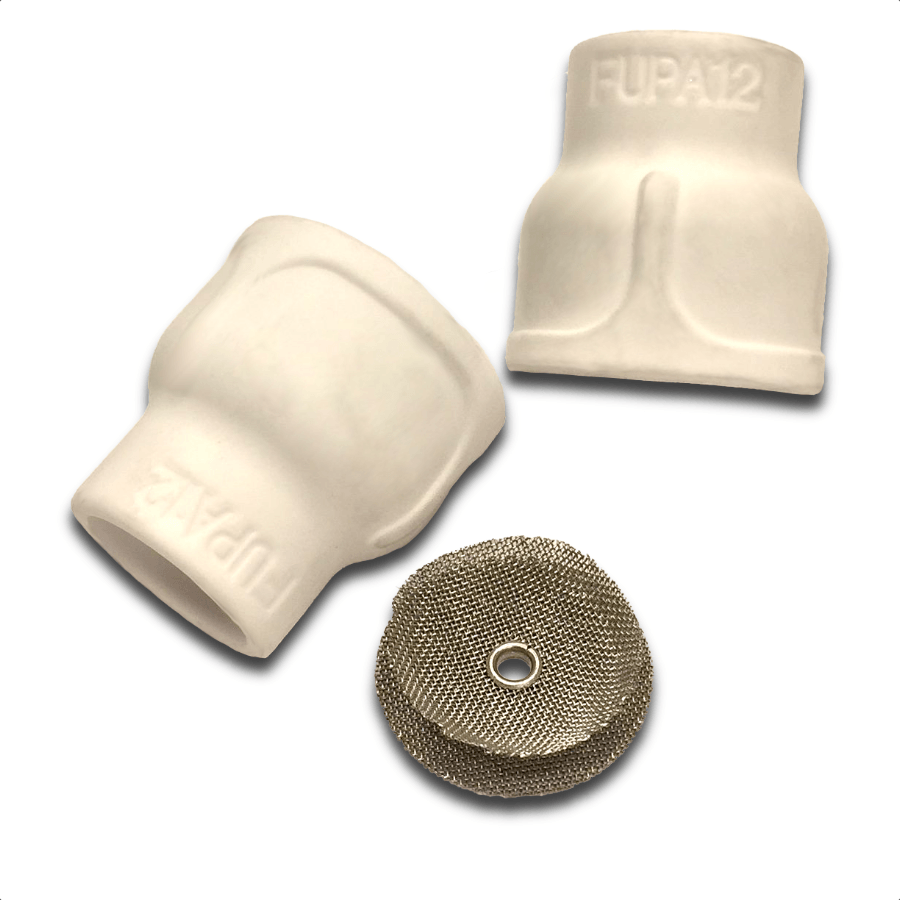

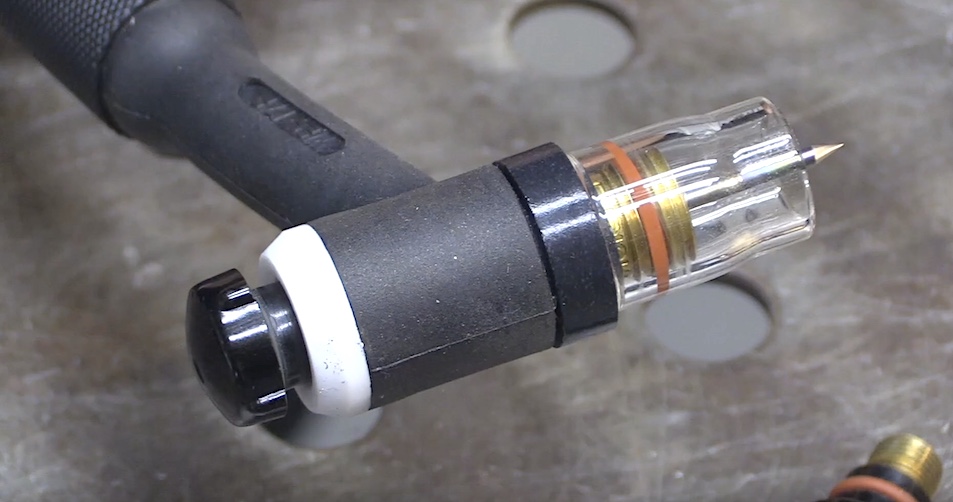

Gas lens cups like the clear 8 pro, Jazzy 10, and Fupa 12 all do a great job of shielding the puddle and give you a larger argon area to shield that hot tip.

You will see a big difference on carbon steel and 4130 chromoly.

And a huge difference on stainless steels.

Notice how completely silver the weld is in the video below.

The furick 12 with 25 cfh works great for tig welding carbon steels, 4130, and stainless.

Weldmonger Furick Arsenal kits available at Weldmonger.com

Arsenal kits have been upgraded to include weldmonger 4 thru 8 pink ceramic cups, a clear 8 cup, jazzy 10 ceramic, furick 12 ceramic, and a BBW clear cup.