TIG Welding Basics part 3

Why do you need Alternating Current for TIG welding aluminum?

Why Cant you Tig Aluminum using DCEN and pure argon?

Why cant you TIG aluminum using DCEP?

Read on or watch the video to learn all about these questions and more.

What exactly is DCEN aka Straight Polarity used for in TIG welding?

Welding Current flows from negative to positive.

So when the electrode is negative, that means the current is flowing from the tungsten electrode into the metal being welded.

That is why TIG is so precise and why on steels, stainless steels, inconel, titanium, etc...a small precise puddle is easy to establish quickly.

What about DCEP aka Reverse polarity

Opposite from electrode negative, the current flows from the metal up through the electrode and that causes the electrode to get really hot...really quick. It makes tigging on dcep very limited.

I say limited because there are actually a small handful of applications where dcep is used for tig.

one example is on magnesium castings.

There is an old TIG report from Union Carbide where DCEP as well as using a 50/50 mix of argon/helium actually provided good results on magnesium castings like aircraft gearboxes.

At a previous job where I worked, this was the process for GTAW mag....until it was changed when tig welders with square wave technology and AC balance became the norm.

Is Alternating current actually a mix of positive and negative current?

Listen, I am no PhD or engineer so technically, I am not sure that statement is correct.

But for the purpose of knowing the effects of welding polarity on TIG , it sure helps to think of AC as a mixture of both good and bad aspects of DCEN and DCEP.

What is the AC balance setting?

On the machine I used in this video, there is what Lincoln calls Auto Correct AC balance.

What that means is that while there is no adjustment knob for AC balance, the machine automatically adjusts the ratio of EP and EN while you weld.

The level of oxidation on the surface of aluminum can affect the level of cathodic etching needed to break up the oxide film.

So this Lincoln TIG 175 senses the resistance and adjusts on the fly.

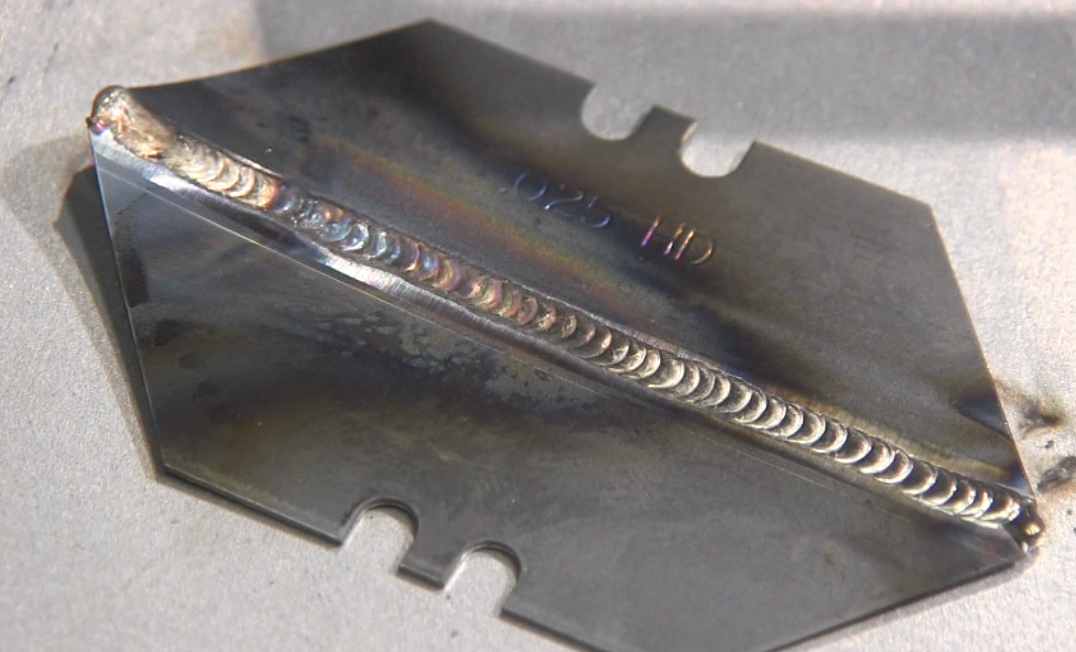

Now personally, AC balance is a setting I like to be able to adjust manually, but results speak loudly and it ran a good bead on aluminum.

I would guess from the band of etching on the edges of the aluminum beads I welded, that the machine default setting is around 65-70% EN.

Watch more TIG Videos