Open Butt Tig Root Pass Techniques

- HOME

- TIG WELDING

- Tig Root

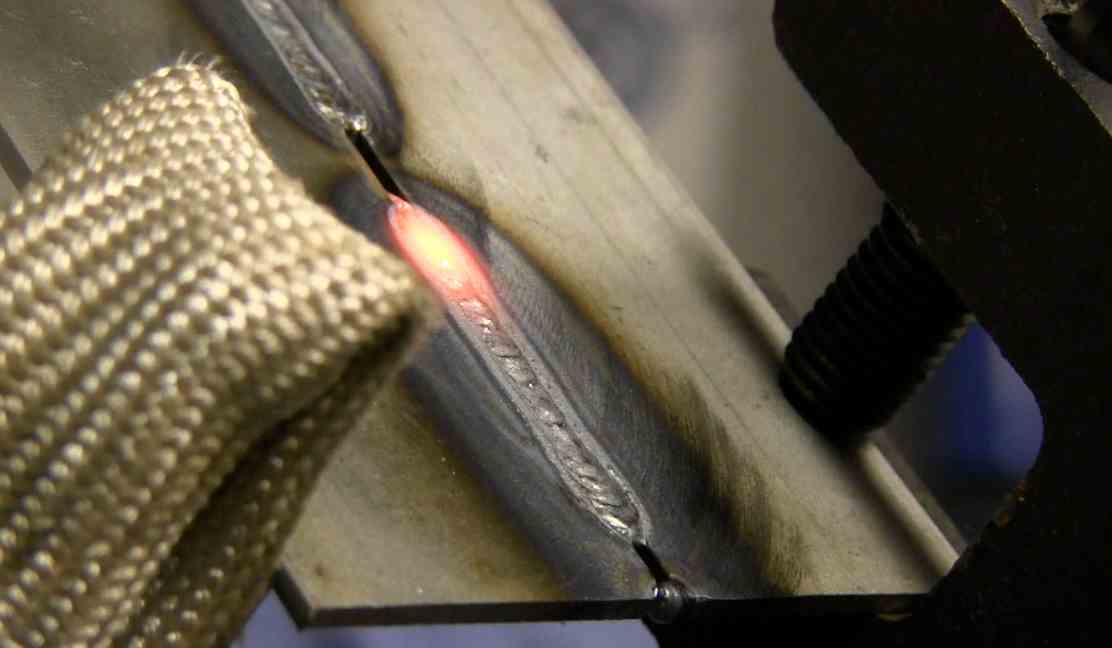

In this video, I am using beveled plates from Triangle Engineering (trieng.com) to dial in the amperage settings for a Tig root pass...on 2" sched 80 pipe.

Can you use plate to verify amps needed for a GTAW root on a pipe test?

This video seems to show that you can.

And since plates are cheaper and easier to reuse than pipe, why not?

TIG Finger Short Videos

Propping on hot aluminum 5f tube to plate weld

If you have every had to prop on aluminum, you know how quickly your knuckles start to heat up.

Propping with a TIG finger® TIG welding aluminum dog feeder

3G weld cover pass Freehand with TIG finger

Tig root Details

The Test plates I got from Triangle Engineering are 3/8" (9.5mm) thick and beveled to 37.5 deg.

After cleaning the mill scale from both sides, I gapped the first plate to almost 5/32" (4mm) and used a 3/32" (2.4mm) rod.

At 90 amps, using a tight arc and very limited side to side movement, a keyhole formed and allowed me to dip rod to fill it.

The important thing to do in order to make sure the root pass pokes thru...is to add rod frequently and also to push a bit of extra rod into the puddle...while also making sure not to weave too wide.

The keyhole should be fairly small and controllable.

if frantic wire feeding is needed to fill the keyhole, that means less amperage should be used.

For the dip keyhole root method, here are the details.

37.5 deg bevel +- 2.5 deg

0 land, 1/8" (3.2mm) gap, 3/32" (2.4mm) filler rod.

90-95 amps

laywire tig root method

The scheme for laywire gtaw root pass on a 37.5 deg bevel plate or pipe is

1/8" (3.2mm) gap, 0 land, and 1/8" (3.2mm) filler rod.

90-95 amps

absolutely zero side to side weave motion is used.

a forward and back motion works best here.

Using a tight arc and minimal torch angle, a slight forward and back motion of the electrode helps push metal on the back side of the plate or pipe.

I freehand the tig root pass to avoid any sideways motion.

Once the root pass is welded, let the piece cool to below 150 f

You should be able to put your hand on the plate without getting burned.

The second pass or hot pass is welded at either the same amperage as the root pass or only slightly hotter...

Amps needed depends on how heavy a root pass... usually 10 amps more is enough.

The goal of the hot pass is to adequately fuse to the root pass without disturbing the back side.

...that usually means using the same or only slightly more heat and moving along quickly...and not spending much time across the middle of the root.

I like to use a 1/8" (3.2mm) rod for the second pass but sometimes, depending on the thickness of metal layed down on the root, a 3/32" (2.4mm) works best.

Watch more tig welding videos