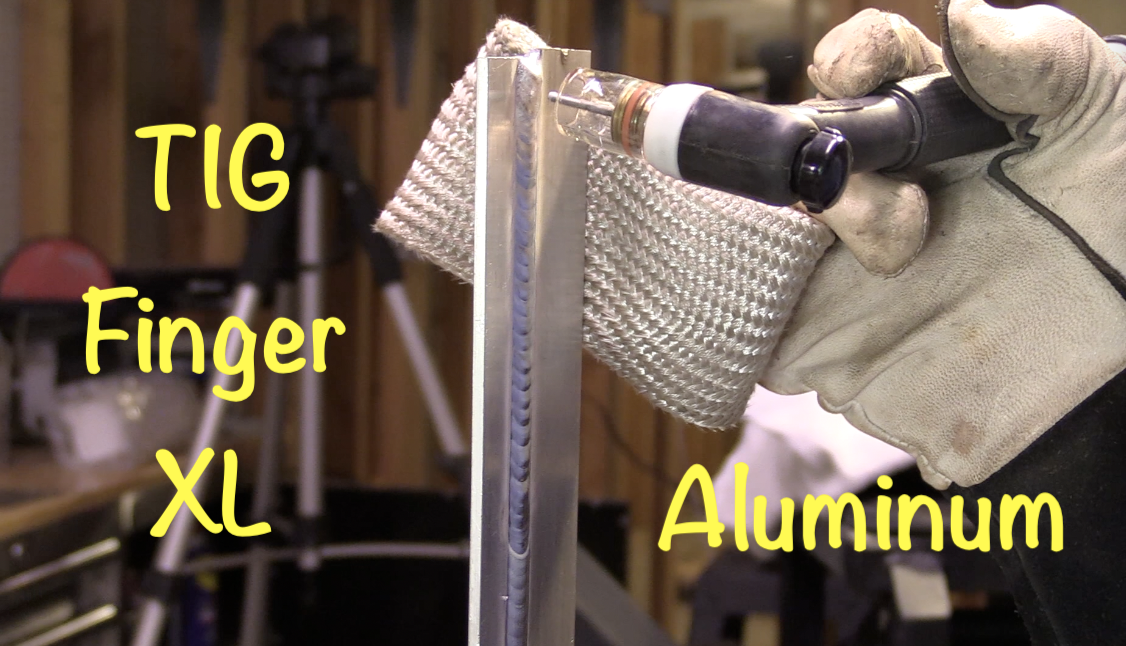

TIG welding an Aluminum 3f lap joint with a TIG Finger® XL

Real life situations for a

TIG Finger® XL

more videos on tig welding aluminum

Details for TIG Welding 3f Aluminum Lap Joint

Base Material Type/Thickness - 6061 t6 Aluminum flat bar .125" (3.2mm)

Prep Method - Acetone wipe followed by stainless wire brush followed by acetone wipe

Filler Metal Type/Size - 4943 3/32" (2.4mm). this is not a typo. 4943 is a hobart filler wire similar to 4043 in the way it flows but properties are better

Tungsten size and prep - 3/32" 2% lanthanated with blunt taper and rounded on tip

Gas Type and Flow Rate - argon 18 cfh

Cup size #8 furick pro clear cup ( normally, I would use a #6 gas lens but the #8 clear cup really helps when filming the arc.

Current/Polarity. AC with AC balance set to 67% EN at 100 hz

Length of Arc - as close as possible without contaminating the electrode

Angle of Travel - torch leaned back 10-20 deg

Manipulation/Technique - move torch ahead to flow puddle down deep into root of joint, pause, lengthen arc, add filler, move ahead with tight arc , repeat

Speed of Travel 5-7 inches per minute

One of the challenges in Tig welding aluminum is to hold a steady arc length so that you avoid duffing the tungsten.

If the arc length is too tight, you will be sputtering the tungsten electrode and having to stop to re sharpen. And when you get aluminum on the tungsten, it really craps up the weld with soot so you just have to stop welding to change electrodes.

That wastes time and really takes the fun out of welding.

if the arc is too long, then it will be difficult to flow the molten puddle into the root of the joint... making it very easy to have lack of fusion in the root.

There are many situations where there seems to be nothing to prop on to steady your hand.

Back around 2010 I came up with the TIG Finger® and then later I made the TIG Finger® XL version for situations where extra heat protection is needed.

This 2 foot long lap joint is just one of many tig jobs where having a prop in your pocket lets you get the job done quickly without burning your fingers.

Other jobs where a TIG finger helps

- sanitary stainless steel tubing in breweries and food service

- coped tube joints in roll cages and chassis work

- pipe welds where walking the cup is not possible or practical

- 4130 chromoly tubing for aircraft fuselages

- injection mold repair where a preheat is required.

- aluminum castings like transmission housings

- stainless steel boat props

- marine tubing for tuna towers

- handrails

- boiler tubing

- small bore stainless pipe....

- any tig welding job that poses problems on where and how to prop and steady your hand.

- 6g pipe tests

"Hey jody just wanted to make a comment on the tig finger. It is by far money well spent I weld mostly thin gauge stainless and like to rest my hand right on the metal when im welding. Even when I repair aluminum diesel tanks for semi trucks I can run 220 amps while resting the ting finger close to the weld with it only gettting warm. Well done. Thanks for the great product" ....Lawrence

---------------------------------------------------------------------------------

"Jody,

this is by far one of the best ideas I’ve ever seen for welding. I work

with an aircraft maintenance company in Orlando, Florida, and that

means A LOT of TIG! I’ve tried the old school trick of cutting a stick

glove thumb and putting it on over my pinky… But with all of the

aluminum and chrome moly, burns were inevitable and horribly painful. I

bought a TIG finger a few months back around Christmas time. By far the

best purchase I made in 2011, no more burns for this guy! Thanks so much

Jody for all you do, any guy that takes time in his day to share his

knowledge, and teach this trade is OK in my book. I wish you the best.

"

John

---------------------------------------------------------------------------------

"First I would like to say that I ordered your Tig finger for myself and a couple of friends.

We all LOVE it. We're seeing more and more

Tig pipe jobs coming up and this has helped a LOT when it comes to being

able to keep one finger on the piece of pipe for stability. Now just

to get a water cooled Tig torch "

~Thanks

---------------------------------------------------------------------------------

"Hi Jody, had my TIG fingers delivered a couple o’ weeks ago, and really, they are great. Last week I had to weld a tricky steel frame with a couple of really nasty spots, and those fingers saved my behind. Without them and with only my gloves I would have had to pause every 30 seconds or so in the tight spots, with them I just went through the job like a hot knife through butter. Thanks a lot and keep welding. Greetings from Berlin, Germany ...Rudi "

---------------------------------------------------------------------------------

"The

tig finger is the best thing you can have for welding tubing in racecar

chassis !! I have never seen anything work this well, no more hot

fingers or bad welds trying to finish in a hot spot this is a great

product well worth the money. Love the tips on aluminum.

"Thanks ,

Mike

" jody,i had to comment on the tig finger.

.. im in the automotive custom fabrication department. i build my chassis, suspension, air tanks, etc etc..

the tig finger is something i will buy from you as long as you sell it!

it speeds up my work, and improved my welds..

IT IS A MUST HAVE FOR TIG WELDING!

.. this website is awesome and you have helped me so much im forever in full support of what your doing here! thanks alot!!!!

"

~Jeff ... Texas