TIG Aluminum Travel Speed

- HOME

- TIG WELDING

- Tig Aluminum Travel Speed

Scroll down for Video

In this video, I am TIG welding beads on the outside edge of 3/16" thick 6061 aluminum with the main goal being cosmetics.

A bead just for looks for a TIG finger display

visit weldmonger.com for TIG kits, TIG fingers, TIG torches, tungsten, filler rod, gloves, tig welding machines, and more

When comes to overall heat input, amperage makes a big difference.

But travel speed can also be one of the biggest factors.

A fairly slow travel speed is fine for learning to TIG weld aluminum.

In fact, placing a ruler next to the bead can help you keep the pace of 1/8 inch per second (which is around 7.5 inches per minute)

But eventually, you will want to increase travel speed for certain applications.

If you are in business for yourself and getting paid by the job instead of an hourly wage, increasing travel speed can make a big difference in your pay.

Final Nuggets from this video

- A slow travel speed with medium amperage can put more heat into a part than a fast travel speed with higher amperage.

- A fairly normal travel speed for a beginner tig welder is only about 7 inches per minute.

- If you are just learning , concentrate on making even uniform beads and don't worry too much about travel speed. Speed comes later

- With aluminum as well as other alloys that are prone to porosity, too fast a travel speed can contribute to porosity because impurities don't have time to outgas or escape as the puddle solidifies quickly.

- using pulse settings of 1pps can help you establish a consistent rhythm and travel speed

- A #6 gas lens cup is a great all around cup for tig welding aluminum

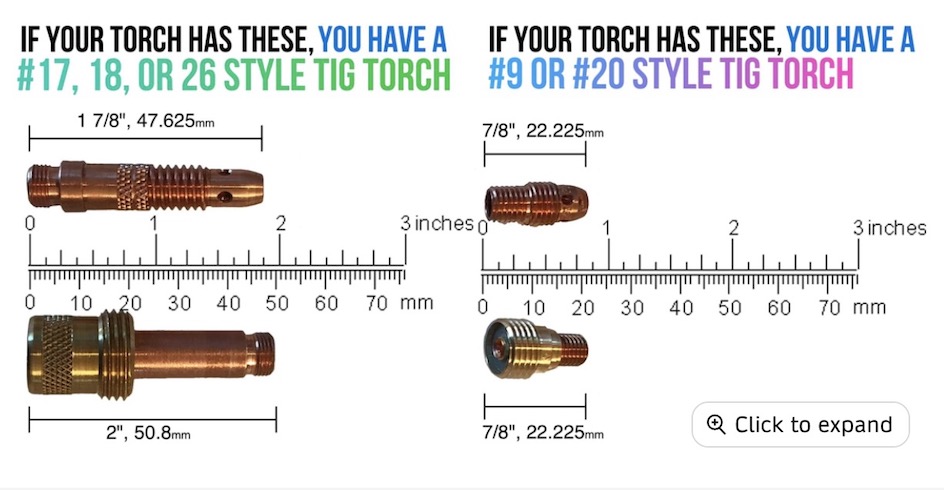

If you have an air cooled 17 style torch, we have a great kit for your torch

If you are still using the standard TIG cups and hardware that came with your machine or TIG torch, I can just about guarantee you will get better results if you upgrade to a weldmonger® stubby gas lens kit.

Aluminum has high thermal conductivity and a low melting point, making heat input important:

1. Heat Input Formula

Heat input in welding is a function of the welding parameters (current, voltage, and travel speed), often expressed in this formula

Heat Input = (Amps × Volts × 60) ÷ Travel Speed (inches per minute)

From this formula, you can see that as travel speed decreases, the denominator gets smaller, resulting in more heat input. Conversely, increasing travel speed reduces the heat input.

- Aluminum conducts heat much faster than steel, meaning the heat you apply to the weld area spreads quickly through the material. This is why aluminum requires more amperage than steel and why it is often helpful to use a preheat for tig welding aluminum thicker than 3/16".

- If your travel speed is too slow, you apply excessive heat to the same area for too long. This can lead to weakened properties in the Heat-Affected Zone (HAZ). In other words, you can weaken the heat affected zone on aluminum by using an excessively slow travel speed.

By increasing travel speed, you reduce the time the heat is concentrated in one spot, limiting the amount of heat absorbed by the base metal.

- Too Slow: Excessive heat input can result in over-penetration or a weld pool that is difficult to control.

- Too Fast: Insufficient heat input can cause lack of fusion or incomplete penetration.

- The right travel speed ensures the heat penetrates just enough into the material for a strong, defect-free weld.

- Welding too slowly wastes time and increases the risk of reduced mechanical properties in the haz.

- A consistent, appropriate travel speed improves productivity without compromising weld quality, especially on large aluminum projects.

The key is finding the right travel speed based on the material thickness, joint type, position, accessibility of weld, and welding parameters to achieve strong clean welds.

There are always exceptions in welding

There are certain welds where travel speed is much of a consideration.

some examples would be:

- oil soaked aluminum castings

- filling in holes

- plug welds

- crack repair