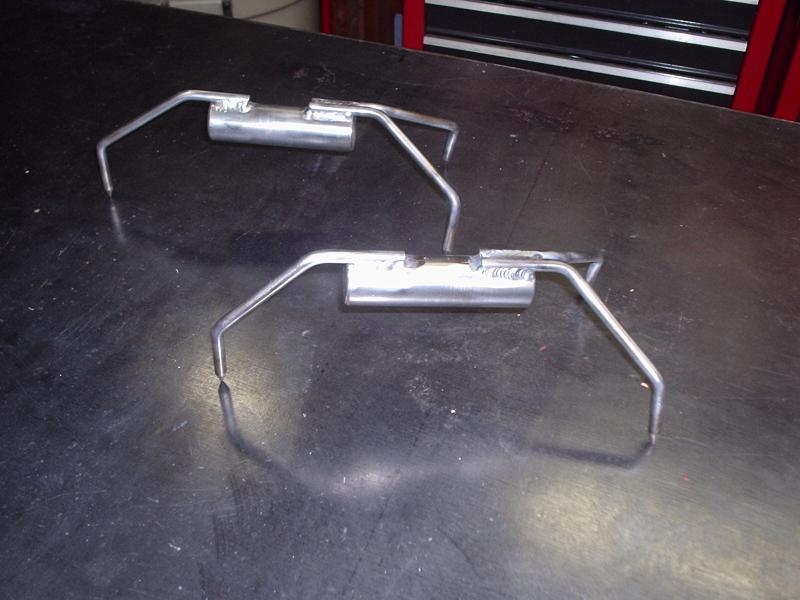

Welders Third Hand with Silicon Bronze Beak

I had a very quick tig job come in the shop the other day where I used

an old raggedy welders third hand to hold down some small gussets while I

got a tack weld on them.

What is a welders 3rd hand?

For the time and effort it takes to make one, a welders third hand is probably one of the most useful tools you can have.

A few pieces of round stock, and a weight....thats all it takes.

I was looking over some posts on our welding forum and came across some

interesting posts of 3rd hand tools and it got me thinking...

I

could use another third hand so after I finished tig welding those

small gussets, I gathered up some scrap pieces laying around the shop

and made one.

Now I am no artist. But for some reason, I thought it would be cool

to add a bunch of silicon bronze weld metal to hold down point to make

it look like a bird skull.

Since 3rd hands kind of resemble a

bird anyway, I thought why not?

Normally I am all about practical stuff and dont like spending extra time or money for stuff that adds no value. But this actually does have a practical purpose.

That big hunk of silicon bronze will help hold parts and will transfer a good ground and not spark.

Why is it important for it not to spark? read on...

Some time ago, I was welding some socket tool inserts into some 4140 steel and noticed an arc spark come off the place where my 3rd hand touched the part.

Now on heat treatable steel like 4140, an arc strike can make a very hard and brittle spot. An arc strike is not a good thing no matter what type of metal you are welding.

So to avoid that from happening in the future, I added some copper alloy weld metal to all three contact points of the 3rd hand tool.

So this third hand I made in this video, will also have silicon bronze weld metal on all three points.

A more practical way to do this could be to weld a small piece of copper tubing on all three points, or some old worn out mig contact tips....or even just wrapping the whole thing with copper braided wire from an old tig torch or welding lead would actually work.

I have made several 3rd hands over the years and I dont ever remember making one that didn't work ...so I dont really think there is any way to screw one up.

So here is what I am asking you to do.

If you have not joined our welding forum yet, you can easily do that right now. You can go there right now and join. Its completely free, there are no meetings to attend, no dues to pay, and by joining, you can post questions, images, use the search function and just enjoy being part of one of the best welding communities out there.

And after you join, why not make your own third hand tool and post the image in the welders third hand thread?