Thin Wall Tubing - TIG Welding &TIG Brazing

What a great Fathers Day gift idea!!

click here to learn more

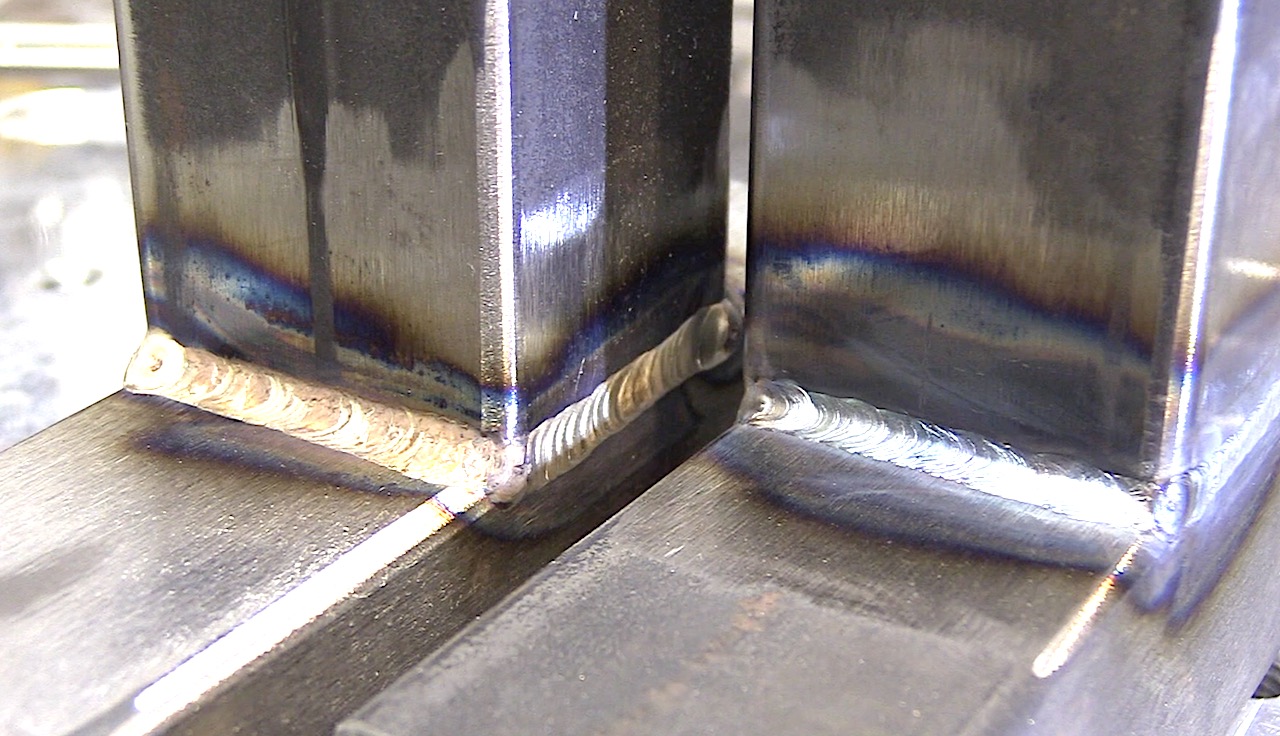

In this video I am doing some TIG Welding as well as TIG brazing on some thin wall square tubing.

One issue I usually have with tig welding thin wall tubing is that it is so easy to penetrate.

I mean obviously you need a certain level of penetration but just not all the way thru.

When you penetrate carbon steel square tubing all the way thru you get oxides in the puddle from the unclean back side of the weld ...and while that is really not a big deal as far as the strength of the weld goes, it does make the puddle wander and makes for a weld that is not as pretty as it could be.

So in order to fix the issue, I like to use a technique called lay wire.

Lay wire technique is simply leaving the rod in the puddle.

By using the lay wire technique along with a larger filler rod, the puddle is cooled off a bit and more deoxidizers are added to the puddle from the filler wire so that oxides and a wandering puddle are not an issue.

(Another thing that sometimes helps is using ER70S-6 filler wire.)

I would normally use .045" or 1/16" rod for .062" wall square tubing but I find that using 3/32" wire and a lay wire technique works better for me.

TIG Brazing at 2 pulses per second

I have been working on some pulse settings for silicon bronze tig brazing for a while now and I think I found a sweet spot for thin wall tubing.

2 pulses per second

33% pulse time

33% background

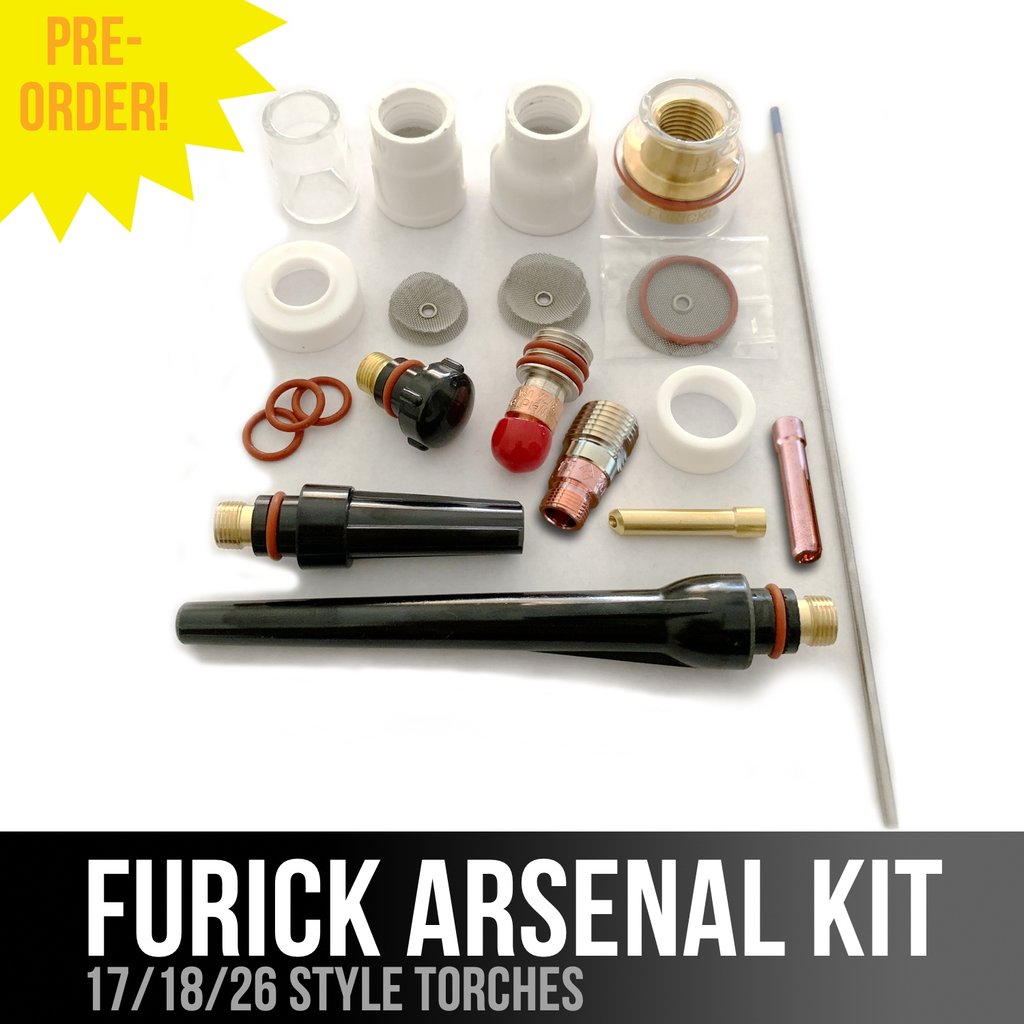

At these settings, I can either use lay wire or dab filler wire and the pulse current along with the JAZZY 10 cup at 22cfh seems to really help control the puddle and keeps it free from oxides