Is Super MissileWeld® just 312 Stainless?

- HOME

- TIG WELDING

- Super Missile Weld 312

312 TIG ROD vs SuperMissile Weld at weldmonger.com

TIG welding filler metal is in stock at Weldmonger.com

What is super missileweld® TIG rod?

Is super missile weld simply 312 stainless TIG Rod?

probably not exactly but they might be very similar

I first heard of super missile TIG Rod when I worked for the TechOps division of Delta Airlines.

One of the shops used it a lot to tack weld hot rolled steel fixtures.

These fixtures were only tack welded and not welded out and so they relied on the strength of the tack welds.

The lead mechanic told me it saved time and he liked having the super missile rod around anyway for odd jobs.

I was working in the metallurgical lab at the time and one of my jobs was operating the XRF spectrometer that we used to identify metals.

So I analyzed a piece of super missileweld® TIG Rod in the XRF and it came up a pretty close match for 312 stainless TIG Rod.

That doesn't mean Super missile rod is exactly the same as 312 stainless because certain elements are hard to detect with XRF.

Then I did some research into maintenance welding rods and I learned that sometimes companies will take a really useful dissimilar metal rod like 312 stainless and give it a catchy name and charge a premium for this "special rod".

And that brought back a memory when I worked at a boilermaker fab shop and encountered a box of Eutectic 680 stick rods and one of the old timers said “you can weld almost anything with that stuff”.

Good chance that eutectic 680 was also a variation of 312 stainless.

Calling a tig rod a catchy name like supermissileweld® instead of the AWS classification number also frees companies up to change the composition a bit….add a bit of boron, silicon or heck even sawdust if they want...because if they don't claim to meet any AWS spec, then they are free to add elements to make the rod even more forgiving than it already is...And 312 stainless tig rod is already very forgiving when it comes to crack sensitivity or hardening due to dilution.

312 stainless TIG Rod is usually way cheaper than super missile weld rod.

Maintenance rods like supermissileweld® typically do not list what is in them. The seller tends to want to keep that a secret.

I suppose sometimes if the composition has been tweaked, that might be a trade secret and proprietary information

But I suspect often times the composition is not provided because it would let the cat out of the bag and remove the super mystery factor.

Here is the nominal composition of 312 stainless TIG Rod

C = 0.15 max

Cr = 28.0 – 32.0

Ni = 8.0 – 10.5

Mo = 0.75 max

Mn = 1.0 – 2.5

Si = 0.30 – 0.65

P = 0.03 max

S = 0.03 max

Cu = 0.75 max

312 stainless TIG Rod is particularly advantageous when the alloy

content of the steel to be welded is unknown.

Features:

Tensile strength - Up to 120,000 psi

Yield strength - Up to 85,000 psi

Ductility - Up to 35% elongation in 2" Hardness as deposited - 200 to 300 Brinell Work hardens

Impact resistance - Excellent Heat resistance - High Frictional resistance – Excellent Abrasive resistance - Mild

Will not respond to heat treatment

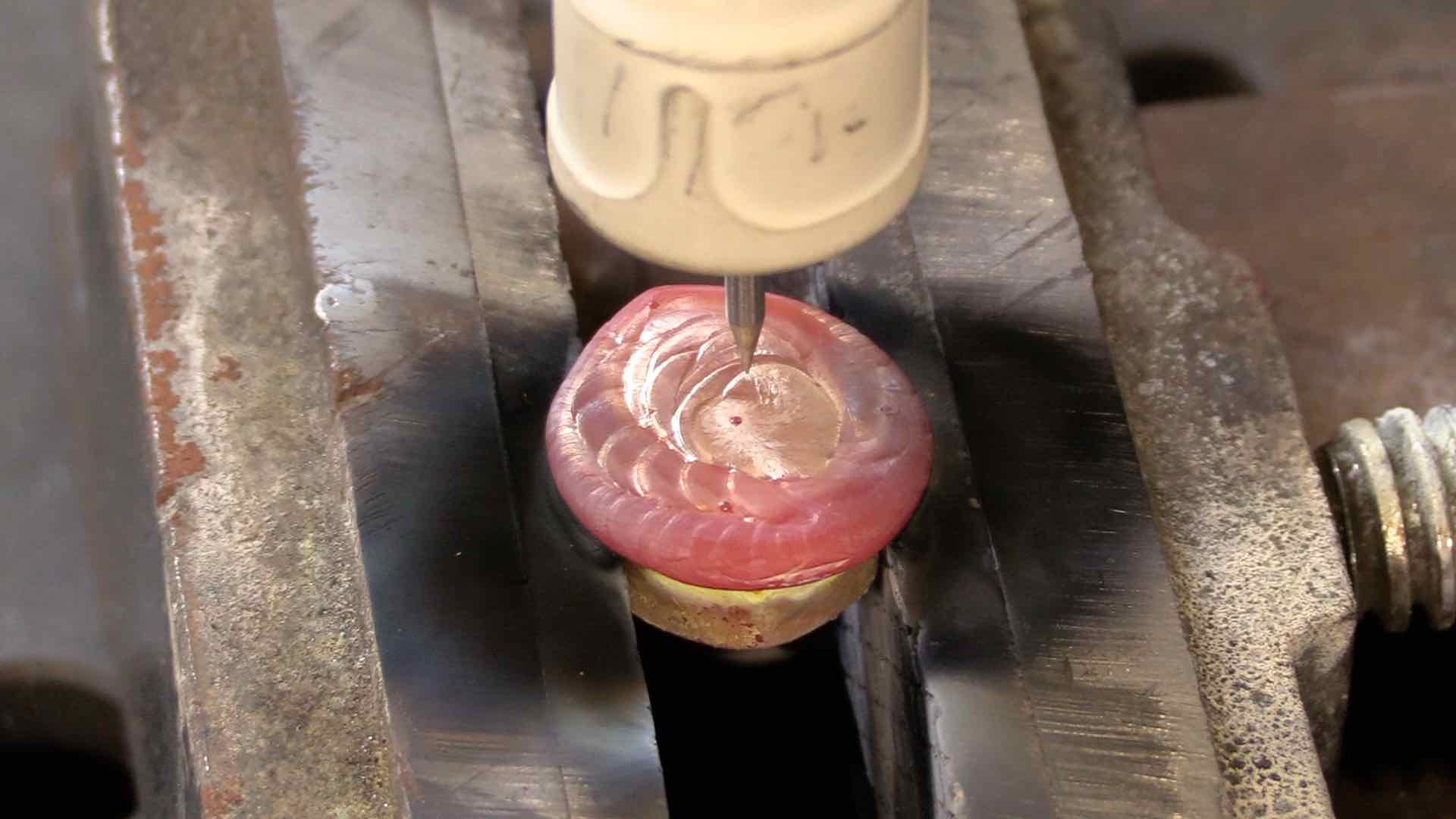

I did a favor for someone recently and I welded a high carbon steel spring loaded pin like the kind you see on gym equipment.

The pin had sheared and showed a fractured surface that looked like this.

A brittle fracture with no bending . partly due to no radius in the corner.

I probably should have turned the job down but I said I would give it a go.

So here is how I approached this little job.

First, I ground down the flat ledge to remove the fractured surface.

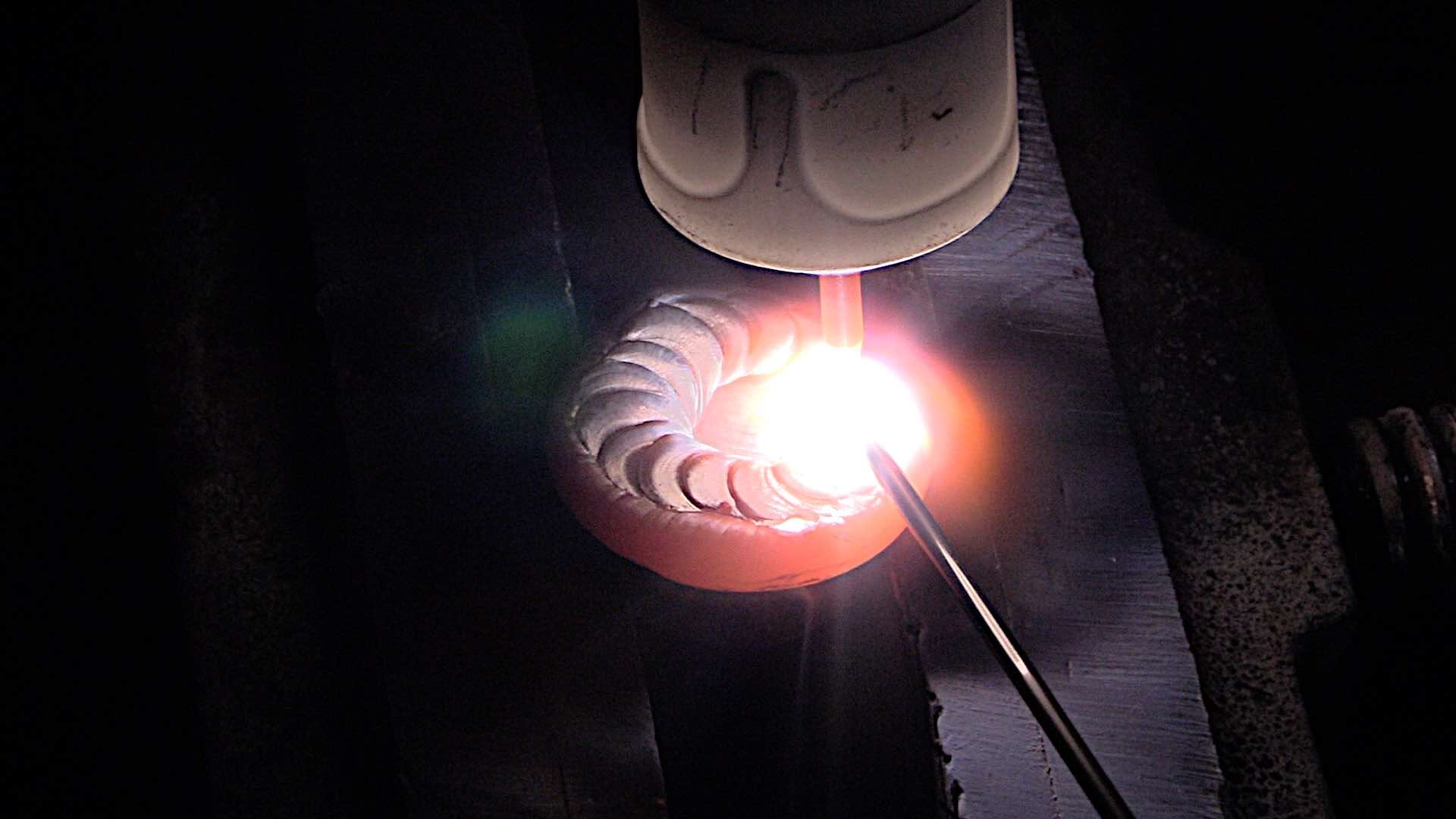

Next, I ran a very small bead of 312 stainless around the edge of the ledge to preheat the part. I used a furick jazzy 10 cup for this to keep all the red hot area shielded with argon.

Then I buttered the surface to be welded with 312 TIG Rod.

After that cooled I sanded the surface smooth.

Then I put the short piece of pin in a drill and used a grinder to put a taper on one end.

Next, I made a center punch mark on the center of the piece with the ledge so that I could center up the sharp point I made on the pin.

Once I had it in place and centered, I used a third hand tool to hold the pin in place.

Small parts like this get red hot all around and weld better if you can keep all sides shielded with argon.

So I used some aluminum foil to make a damn to trap argon on the back side.

When I first tack welded the piece I let the arc heat up the pin for a few seconds as kind of a preheat. The actual pin I welded was only around 1/2” long and only about 5/16” diameter so it got red hot quickly.

I welded the pin out using 312 stainless TIG Rod and let it cool slowly and left the weld on the pin.